Crathco

®

5000 Series Manual Page 19

Ann

ual Maintenance (cont.)

4. Remove dasher assembly, inspect stator bearings and replace shaft seal set. (See Care and Cleaning).

5. Remove rear panel and inspect "V" belt.

6. Inspect the drive shaft square hole for wear (rounding-out).

7. Check drive shaft and motor shaft bearings for excessive wear.

8. Reinstall side and back panels.

9. Re-connect power supply.

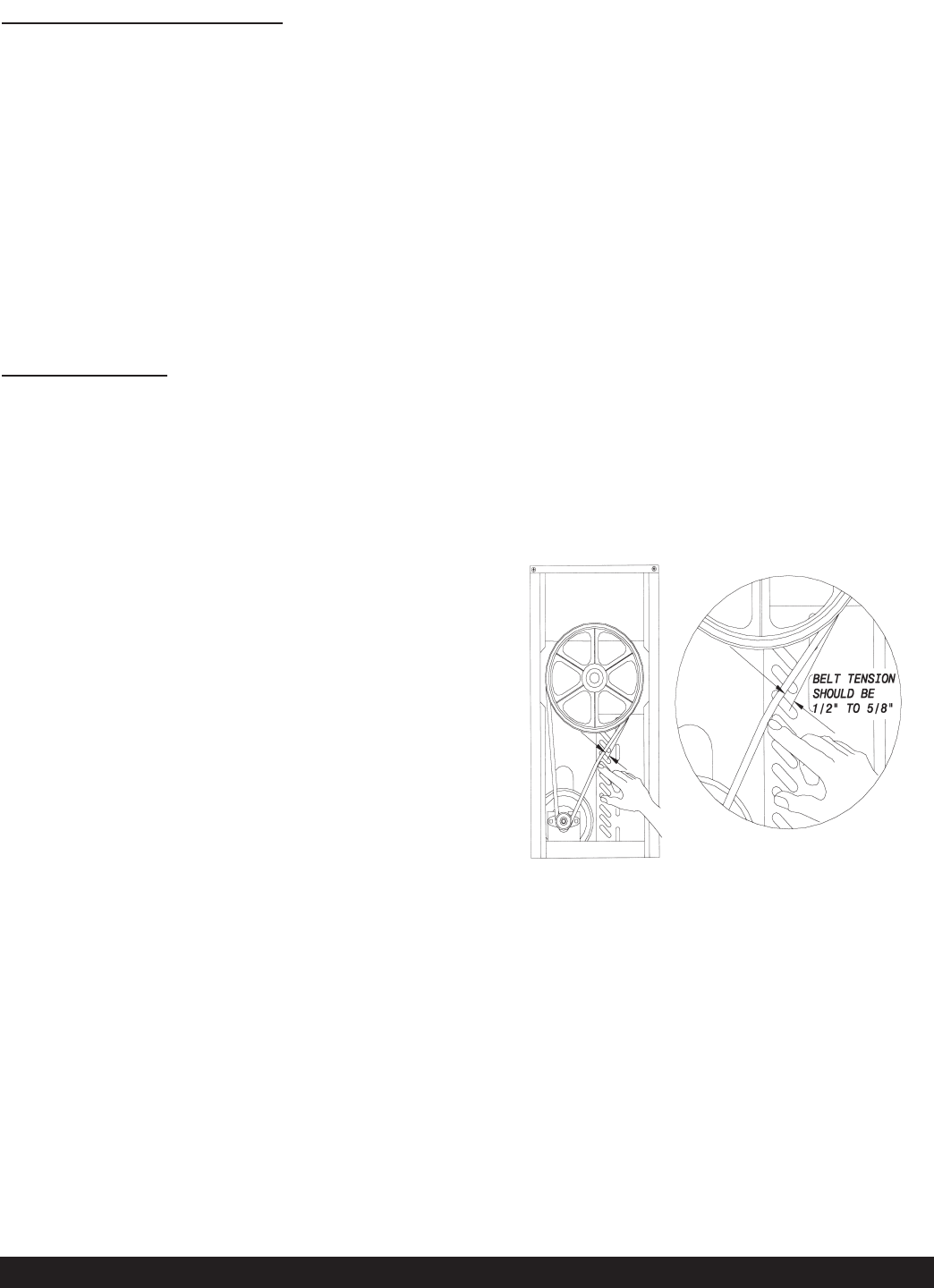

Belt Adjustment

Check the belt tension. The proper belt deflection is 1/2" overall. If the deflection is more than 1/2" the motor will

need to be lowered. If the deflection is less than 1/2" the motor will need to be raised. Follow this procedure to

adjust the motor to achieve proper belt tension.

1) Unplug the machine and remove both side and the rear

panels.

2) Locate the motor flange bearings (#W038.0009). These

are the pillow block bearings that hold the motor to the

cradle. The motor is double shafted and the shaft extends

through a bearing on each end. The bearing is held to the

motor cradle by two allen bolts on each bearing.

3) Loosen the allen bolts on each bearing. Do not loosen the

set screws that hold the bearing collar to the motor shaft.

4) Lower the motor or raise the motor as needed. The motor

must be kept level from front to back. Do not lower or raise

only one end of the motor. This will result in excessive belt

wear and belt noise.

5) Tighten all four allen bolts down. Align the motor pulley with the top pulley if needed.

6) The motor pulley should be in alignment with the large (driven) top pulley. Use a straight edge along the

top pulley.

7) If the pulleys are not in alignment, remove the setscrew from the motor pulley and move either in or out as

needed.

8) Reinstall the setscrew. Use non-permanent loc-tite on the setscrew and tighten it back down on the motor

shaft. Be sure the setscrew is tightened down flat on the motor shaft.

9) Return the unit back to service.

CAUTION: Unplug the machine before performing any adjustments. This procedure

must be done by a qualified technician.

ƽ