5

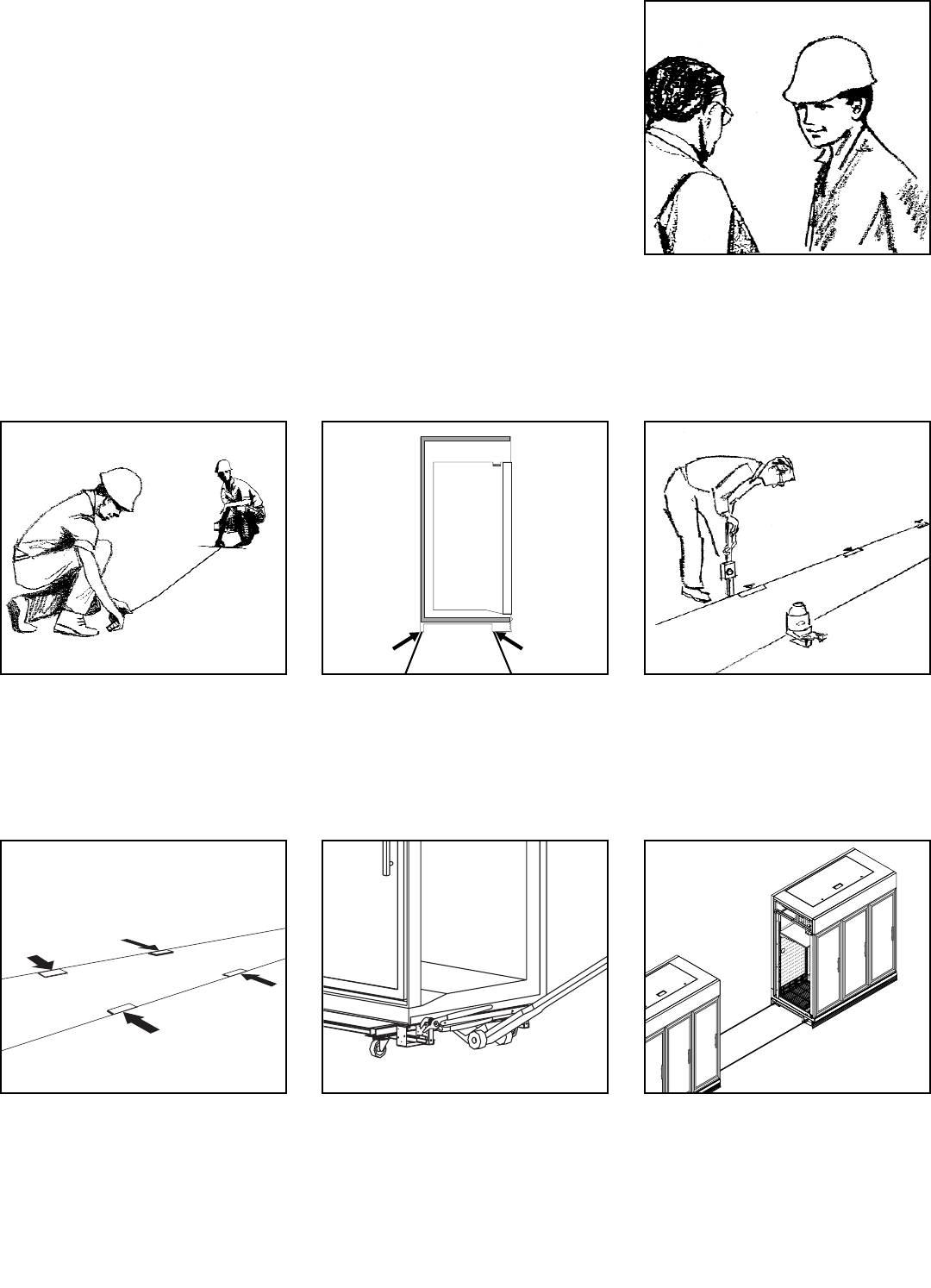

Set Shims On Basehorse Locations

Locate basehorse positions along chalk

lines. Spot shim packs at each

basehorse location.

4

Level Floor. Use Laser Transit

Leveling is necessary to assure proper

case alignment. Locate highest point on

chalk line as reference for

determining height of shim-pack

levelers. A laser transit is recommend-

ed for precision.

7

Position Next Case In Line Up

Roll case approximately 6’ from adjoin-

ing case. Remove casters on the end

nearest to the next case. Allow casters

to remain on opposite end to assist in

pushing cases together - then remove

them.

6

LINE UP &

TRIM OUT

BASE RAIL

BASE RAIL

1

Consult With General Contractor

Ask the general contractor if there have

been changes in the building dimen-

sions since the print you are using was

issued. Also, ask the points of reference

from which you should take dimensions

to locate the cases.

2

Snap Chalk Lines

Mark floor where cases are to be

located for the entire lineup.

3

Snap Lines On Base Rail

Locations

Snap lines where base rails are posi-

tioned, not the front or back edges of

the cases. See case cross section

drawing, page 3, for rail location dimen-

sions.

6

Position First Case In Lineup,

Remove Casters, Level

Roll first case into position. Raise case

from end under cross support using

“J” bar. Remove cotter pins, casters,

and outriggers. [CAUTION! Keep hands

from under case] Level case on shims.

Now that cases have been positioned and leveled, you may

proceed to trim-out case lineup. Trim parts have been

designed to be applied easily with only a small number of

fasteners required. Most external parts are adjustable to

achieve almost invisible, snug-fitting joints and a high level

of excellence in fit and finish.