– 8 –

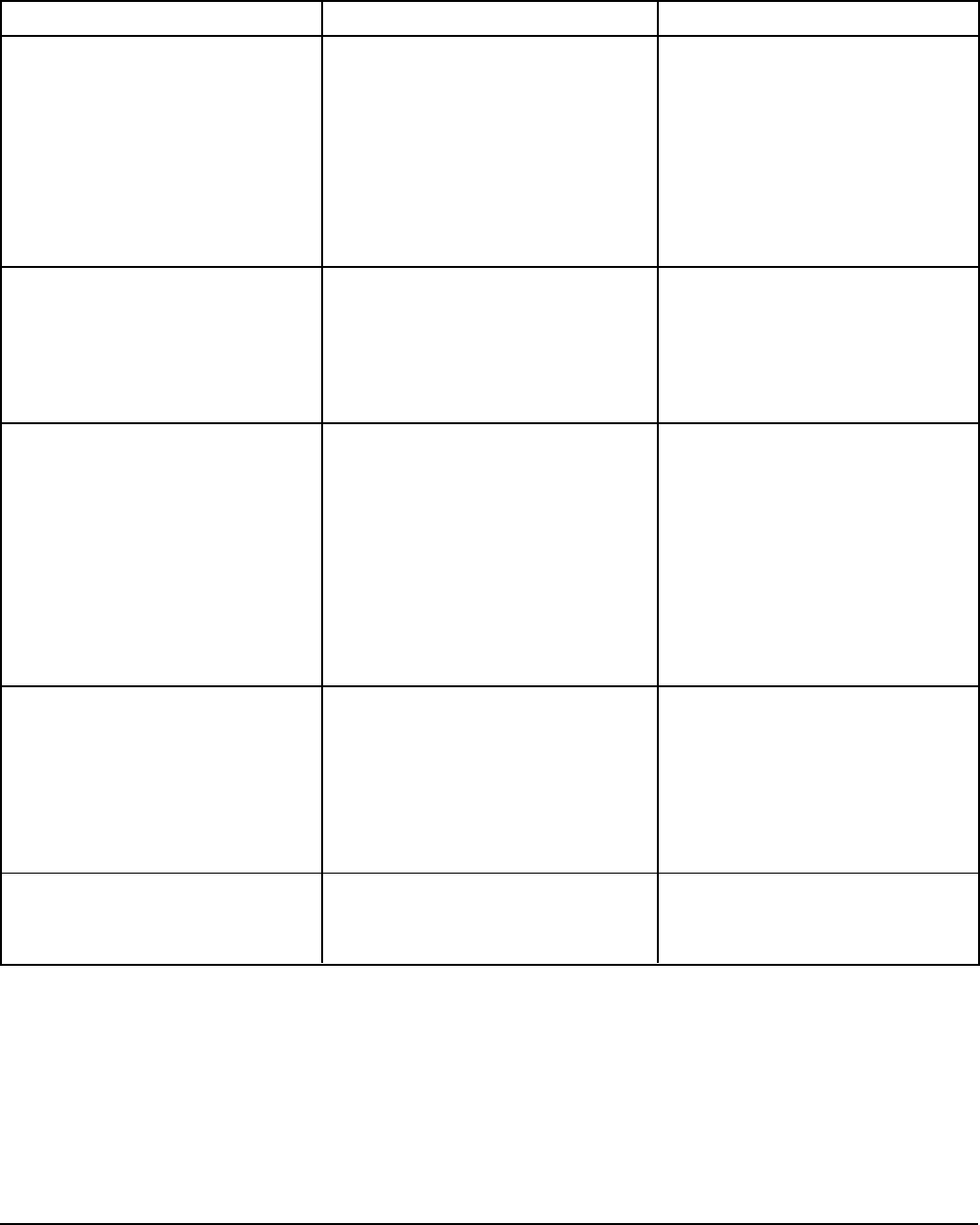

TROUBLESHOOTING

FAULT

Motor won't start.

Machine stops while operating and

won't restart.

Low output or bad cutting results.

Scraping sounds.

Cutting tool locked to shaft.

POSSIBLE CAUSE

A. Feed hopper not locked in

correct position.

B. Pusher plate raised.

C. Fuse or circuit breaker

interrupting power.

A. See B and C above.

B. Motor is overloaded and motor

is too warm.

A. Wrong cutting plates were

used.

B. Slicing, shredding, dicing or

Julienne cutting plate is not

OK.

C. Excessive feeding pressure.

A. When dicing, dicing grid not all

the way down to proper

position.

B. Locking screw not mounted.

A. Product built-up in machine.

REMEDY

Make sure feed hopper is locked

correctly.

Turn pusher plate clockwise and

lower it.

Have electrician check circuit.

Allow the motor to cool; motor

protector will allow restart when it

has cooled.

Refer to CUTTING TOOL GUIDE.

Make sure plates are intact and

sharp.

A light feeding pressure is best for

most products.

Stop machine immediately.

Remove dicing grid and clean side

wall and ledge in cutting tool

chamber.

Mount the locking screw.

Carefully rotate the cutting tool

clockwise with a little force.

FORM 33530 Rev. A (3-98) PRINTED IN U.S.A.