– 2 –

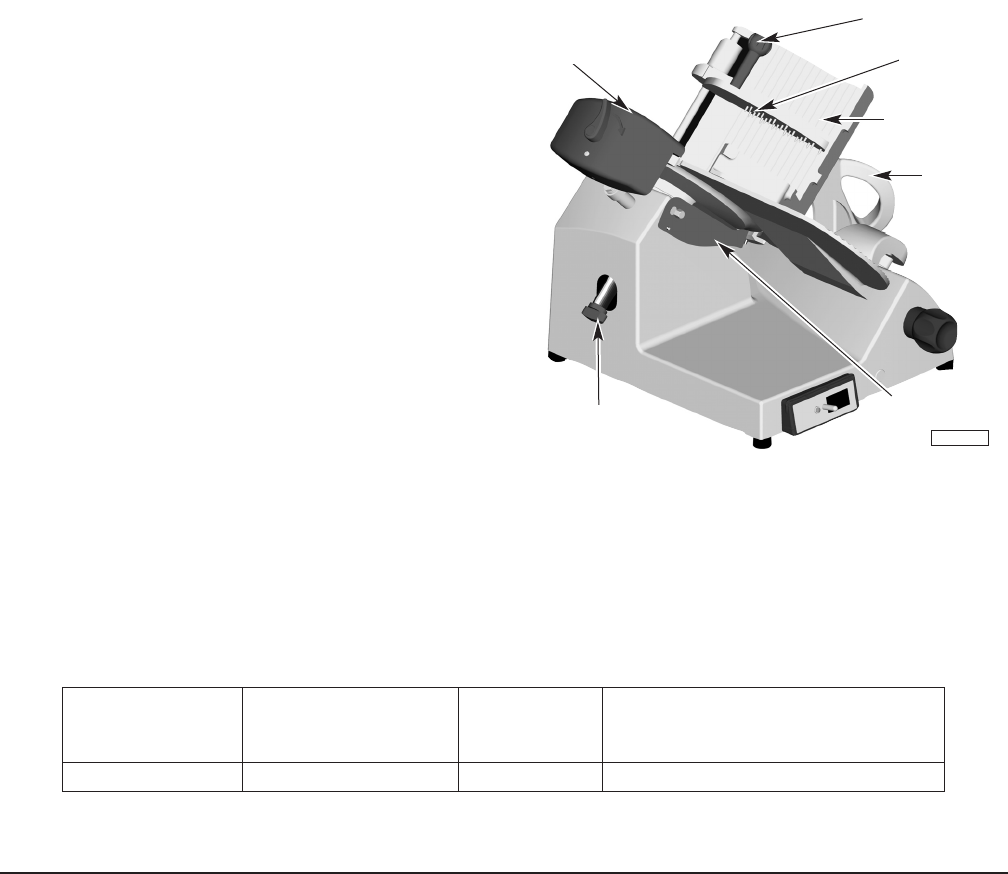

MEAT GRIP

MEA

T GRIP HANDLE

SHARPENER

CARRIAGE TRAY

CARRIAGE

HANDLE

PL-41551-1

KNIFE COVER KNOB

DEFLECT

OR

Installation, Operation and Care of

EDGE SLICER

SAVE THESE INSTRUCTIONS

GENERAL

The Edge slicer is equipped with a

1

⁄

3

HP motor. A cord and plug is furnished as standard equipment.

The slicer knife is chrome-plated forged carbon steel. The slicer base, carriage tray support arm,

knife cover, ring guard and gauge plate are made of smooth-finish anodized cast aluminum for easy

cleaning. The rear-mounted meat grip is hinged on the rod behind the carriage tray. The top-mounted

knife sharpener is removable for cleaning.

The Edge slicer must be thoroughly cleaned and sanitized after installation and before being used.

Refer to Cleaning, page 3.

INSTALLATION

UNPACKING

Immediately after unpacking the slicer, check for

possible shipping damage. If the slicer is found to

be damaged, save the packaging material and

contact the carrier within 15 days of delivery.

Prior to installing the slicer, test the electrical service

to make sure that it agrees with the specifications

on the machine data plate. The data plate is located

on the right side of the slicer base.

The CARRIAGE TRAY SUPPORT ARM is secured to the

slicer by turning the K

NOB below the SUPPORT ARM

clockwise until snug (Fig. 2).

Mount the SHARPENER on top of the slicer (Fig. 1)

by lowering it onto its post. The S

HARPENER can be

removed for cleaning.

The DEFLECTOR (Fig. 1) should already be mounted

below the knife.

ELECTRICAL

WARNING

: THIS MACHINE IS PROVIDED WITH A THREE-PRONG GROUNDING PLUG. THE

OUTLET TO WHICH THIS PLUG IS CONNECTED MUST BE PROPERLY GROUNDED. IF THE

RECEPTACLE IS NOT THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN.

ELECTRICAL DATA

Model Volts / Hertz / Phase Machine Amps

Minimum Circuit Ampacity

Maximum Protective Device

AMPS

EDGE 120 / 60 / 1 3.5 15

Compiled in accordance with the National Electrical Code, NFPA 70, latest edition.

© HOBART CORPORATION, 2002

Fig. 1