12

CLEANING STAINLESS STEEL

SURFACES

–

Generally soap and water will be

sufficient for most cleanings when done of-

ten and regularly. When necessary, sev-

eral cleaning agents can be used. Some of

themare Comet, Bab-O, Liquid NuSteel,

Cooper’s Stainless Steel Cleaner, and Al-

len’s Stainless Steel Cleaner.

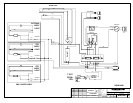

REFRIGERATION

–

The GSVM models employ a refrig-

eration system using a hermetic compres-

sor. The GSVM4060 and GSVM4072 sys-

tems employ a capillary tube for refriger-

ant flow control. The capillary tube is sol-

dered to the suction line pull-out coil for

proper heat exchange. If the capillary

should become plugged or damaged for

some reason it is best to replace the whole

heat exchanger with a new one. Consult

the factory for the proper replacement.

The GSVM-5272 employs a bleed

port type expansion valve for proper re-

frigerant control.

As stated previously, these cases are self-

contained with the condensing unit

mounted at the bottom. They are

equipped with a hermetic compressor and

a capillary tube. The condenser is of fin

and tube construction and SHOULD BE

PERIODICALLY CLEANED TO MAIN-

TAIN EFFICIENT OPERATION.

If for any reason the cabinet must

be recharged, consult the serial plate found

inside the cabinet for the proper refriger-

ant charge and weight.

If it should become necessary to leak

test the system, please adhere to the follow-

ing notice:

BECAUSE OF THE CFC ATMOS-

PHERIC CONSIDERATIONS BEING

TAKEN TODAY, WE ASK THAT LEAK

TESTING BE DONE WITH REFRIGER-

ANT 22 MIXED WITH NITROGEN

LEAK TESTING

–

The test gas cylinder must be

equipped with a pressure gauge and regu-

lator so that system test pressures do not

exceed maximum allowable limits. Do not

ever use anything other than a R-22/

Nitrogen mixture for leak testing.

Attach a refrigerant test gas cylin-

der to your service manifold and connect

the manifold to the charging port on the

liquid line valve.

Charge an R-22/Nitrogen mixture

into the system, raising the pressure to the

unit’s nameplate for the low side and high

side pressures. Using an electronic detec-

tor, carefully check the entire system for

leaks. Take special care to inspect all

brazed and flare connections.

EVACUATION

–

After the system is proven leak

tig ht, thor oughly ev acu ate the s yst em ac-

cording to the following procedure:

a. Discharge the refrigerant-nitrogen mix-

ture, allowing it to blow from the sys-

tem as rapidly as possible, into any

empty cylinder.