9 166240009

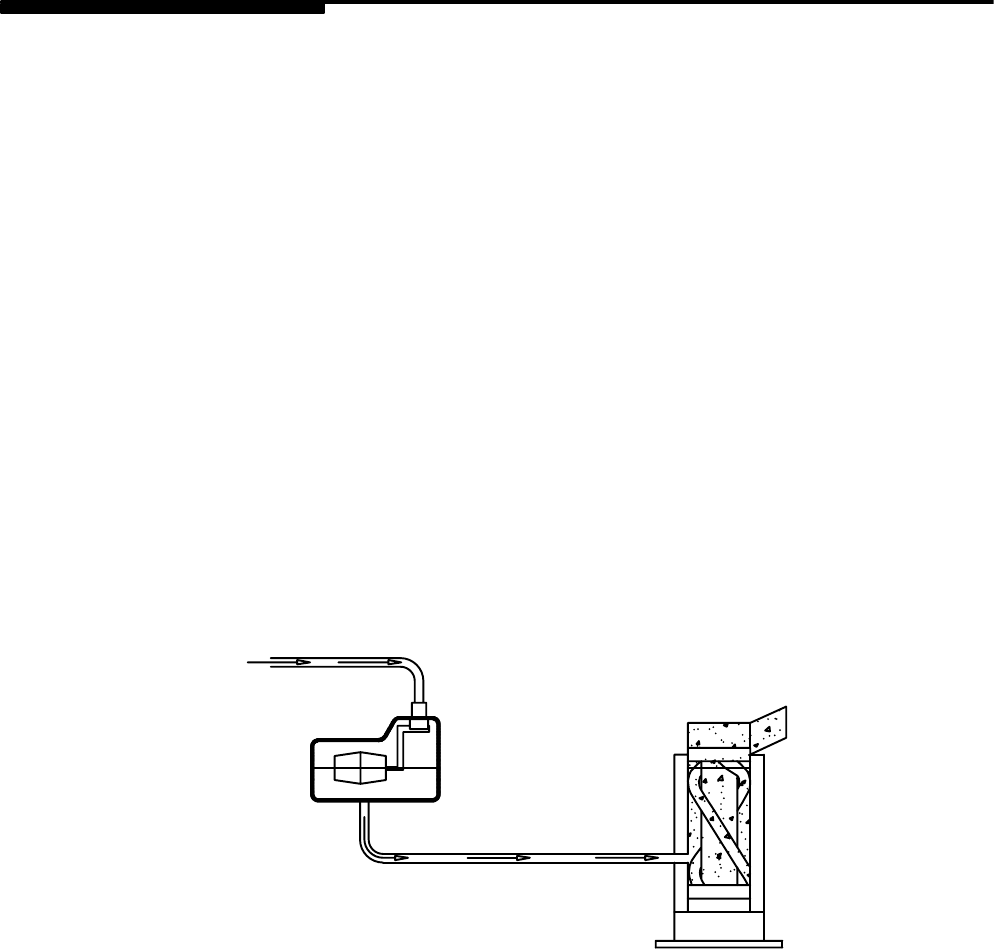

TYPICAL WATER CIRCUIT

The supply water enters the float chamber through a small orifice. The water level rises and lifts the buoyant

float with it. The float attached to the float arm seats a valve to shut off any further water supply. As water

leaves the float chamber, the level drops along with the float and arm, causing the valve to open and admit

more water. Thus the water level is maintained automatically as the machine operates.

Water now flows through a hose connected to the float chamber and enters the opening of the evaporator shell.

The water level in the shell will rise to the same level that is maintained in the float chamber. The water that is

in immediate contact with the center post evaporator will be reduced in temperature. As a result, freezing

occurs and ice forms on the surface of the evaporator.

As more water is frozen, the thickness of the ice increases until it exceeds the distance allowed between the

evaporator and auger. The auger rotates at a slow speed to wipe off the accumulated ice as well as help it to

the surface. After the ice reaches the surface it is discharged through the top opening in the shell. An ice chute

attached to the shell conveys the ice to the storage bin where it accumulates in the insulated bin until it is used.

The ice will pile up to a point where the bin thermostat tubing is located. When the ice touches this brass

tubing, the unit will shut–off and remain off until enough ice is used or melted to reduce the pile. Any ice that

melts will pass through the drain and drain hose to an open drain.

OUT

ICE

EVAPORATOR

CHAMBER

FLOAT

CHAMBER

WATER IN

FIGURE 4. TYPICAL WATER CIRCUIT