3

620916501INS

INSTALLATION INSTRUCTIONS

1. Locate the dispenser indoors on a level counter top.

The ice dispenser must be sealed to the counter. The MOUNTING TEMPLATE (see Figure 3)

indicates where openings can be cut in the counter. Locate the desired position for the dispenser, then

mark the outline dimensions on the counter using the MOUNTING TEMPLATE. Cut openings in the

counter.

Rotate the line support bracket, located under base, to the up position and route all the lines below the

bracket.

Apply a continuous bead of National Sanitation Foundation (NSF) listed silastic sealant (Dow 732 or

equal) approximately 1/4” inside of the unit outline dimensions and around all openings. Then, position

the unit on the counter within the outline dimensions. All excess sealant must be wiped away

immediately.

2. The beverage tubes, drain tube and power cord are routed through the large opening in the bottom of the

unit. See the MOUNTING TEMPLATE (see Figure 3), for locating the required clearance hole in the counter

for these utility lines.

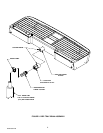

3. DRIP TRAY DRAIN ASSEMBLY (see Figure 2). Route the drain tube to an open drain with the end of the

tube above the “flood” level of the drain. Use the tubing, fittings, clamps, and insulation provided with the Dis-

penser to assemble the drain. The completed drain line must pitch continuously downward and contain no

“traps” or improper drainage will result.

NOTE: This equipment must be installed with adequate backflow protection to comply with federal, state,

and local codes.

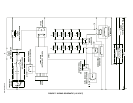

4. Connect the beverage system product tubes as indicated in the Flow Diagram. This work should be done by

a qualified Service Person. Any non-carbonated water tubing must be connected to the outlet of the check

valve.

Note: See the Flow Diagram (see Figure 4) or decal on lower front panel of the unit for the location of syr-

up and water connections.

Note: Water pipe connections and fixtures directly connected to a potable water supply shall be sized,

installed and maintained according to Federal, State and Local Laws.

5. ICE PORTION CONTROLLER:

Regulated CO

2

gas pressure is required to operate the portion control dis-

pensing system. Proceed as follows to connect the CO

2

gas pressure source line to the dispenser.

A. Connect and route the CO

2

line from outlet side of the source regulator assembly up to the dispenser.

NOTE: That the minimum source-regulated pressure is 40 psig.

B. Connect the CO

2

source line to dispenser inlet line labeled “CO

2

“.

C. The dispenser regulator outlet pressure is factory preset to 34 psig ± 2 psig DO NOT ADJUST.

IMPORTANT: Maximim CO

2

operating pressure is 50 psig.

6. Clean the hopper interior (see Owner’s Manual P/N 620916502 for cleaning instructions).

7. Connect the power cord to a 120 volt, 60 cycle, 3–wire grounded receptacle.