39

200 Series Technical Manual

7610-100-45-00 Rev. E (02/10/2006)

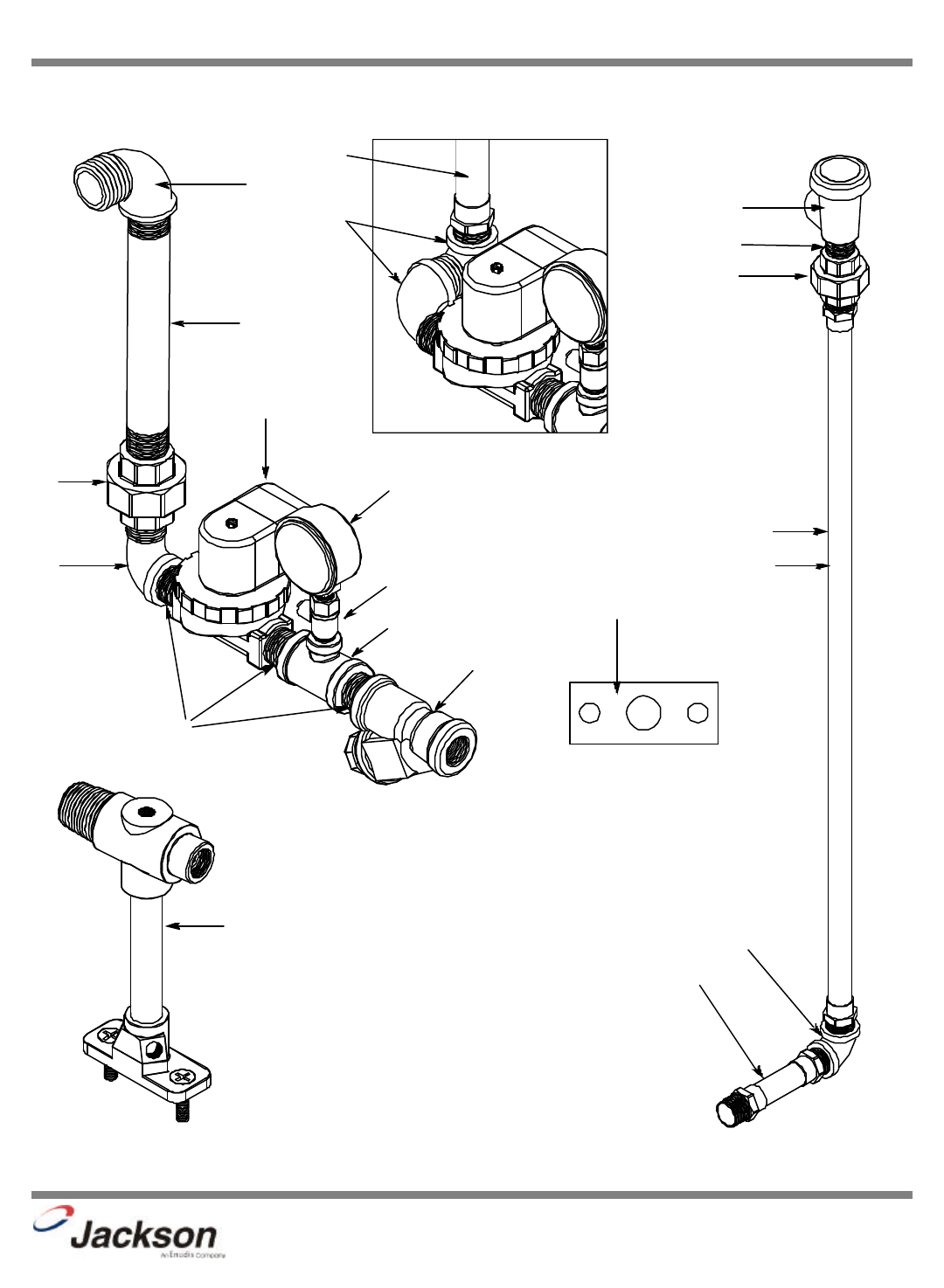

SECTION 6: PARTS SECTION

INCOMING FILL PLUMBING/OUTLET PLUMBING

200B INCOMING FILL PLUMBING

200/200LT INCOMING FILL PLUMBING

200B OUTLET PLUMBING

10

5

8

11

12

7

7

12

9

6

7

8

3

13

2

1

5

4

14

16

15

When servicing plumbing components, take care not to

damage the threads of each individual item. Damaged

threads can cause leaks and loss of pressure, which

could adversely effect the performance of the Tempstar

dishmachine. It is strongly recommended that teflon

thread tape, used in conservative amounts, be applied

to threads when joining components together. It is not

advised to use thread sealing compounds, sometimes

referred to as “pipe dope”. Compounds can be ejected

from the threads during the tightening process and

become lodged in key components, thereby rendering

them useless. Some of the components include the

solenoid valve and the pressure gauge isolation ball

valve.