The drive motor and the gear reducer of your Jackson

rack conveyor are responsible for moving racks of ware through

the dishmachine. If needed to be replaced, these instructions will

show you how to get your machine up and running in the shortest

possible time.

Jackson offers all of the repair parts necessary for per-

forming this task.

The instructions provided here are for maintenance per-

sonnel only. Unauthorized persons should not attempt any of the

steps contained in these instructions.

Warning: many of the instructions and steps within

this document require the use of tools. Only authorized per-

sonnel should ever perform any maintenance procedure on

the dishmachine!

PREPARATION

1. Power must be turned off to the unit at the service

breaker. Tag or lock out the service breaker to prevent accidental

or unauthorized energizing of the machine.

TOOLS REQUIRED

The following tools will be needed to perform this mainte-

nance evolution:

1. 7/16” socket and ratchet with extension

2. 9/16” socket and ratchet with extension

3. 7/16” combination wrench

4. 9/16” combination wrench

5. 3/4” combination wrench

6. 1/8” Allen wrench

7. 1/4” nutdriver

8. Large flathead screwdriver

9. Medium phillipshead screwdriver

10. Medium hammer

11. Rubber mallet

TIME REQUIRED

It is estimated that it will take (1) person one and a quar-

ter hours to replace the drive motor, one and a quarter hours to just

replace the gear reducer or two hours to do both at one time, not

including all of the items indicated in the section entitled “PREPA-

RATION”.

IMPORTANT NOTES

1. Read these instructions thoroughly before attempting

this maintenance procedure. Become familiar with the parts and

what actions need to be taken. This will save time in the long run!

2. The procedures demonstrated in this manual are

shown being performed on an AJ-44 rack conveyor dishmachine.

The actual maintenance steps, however, apply to any drive motor

or gear reducer found on a Jackson rack conveyor dishmachine.

STEPS

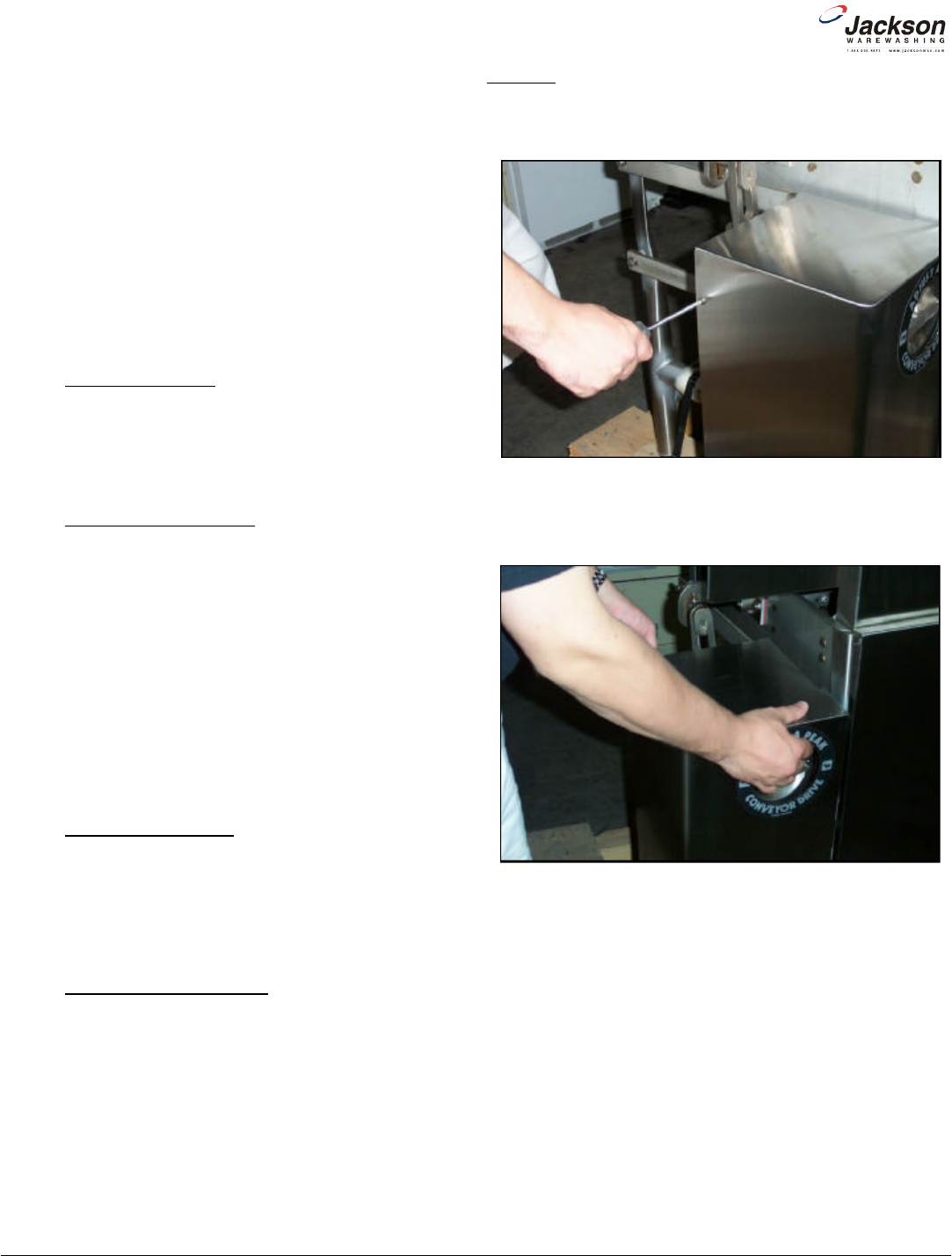

1. Remove the (2) screws that secure the top drive assembly cover

in place.

2. Remove the top cover to expose the drive assembly.

3. Set the top cover to the side and out of the way so that it does

not become a trip hazard. From here, the next step will be to

remove the bottom cover. This will require using the 7/16” socket

with ratchet and most likely the 7/16” combination wrench. Do not

lose the hardware for the covers as your repair kits do not come

with the hardware necessary to replace these. If you do require

hardware that is not present in your kits, do not hesitate to contact

Jackson Technical Service for help.

www.jacksonmsc.com

Rack Conveyor Drive Motor and Gear Reducer Replacement Instructions

Revision A (07/05/2005)

2

Removing the top cover.

Removing the screws from the top cover.