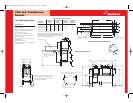

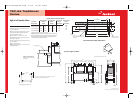

Conveyors

TSC-66 Traditional

Series

Specifications

NOTE:

The TSC-66 series conveyor dishmachines are

N

SF International Inc. (NSF) and Underwriters

Laboratories Inc. (UL) listed. They also meet the require-

ments of A.S.S.E. Standard No. 1004.

PERFORMANCE:

Fully automatic, single tank, rack

conveyor dishwasher designed to wash, rinse, and sani

-

tize tableware and utensils commonly associated with

the preparation and consumption of food items in a com-

mercial foodser

vice operation. Sanitization is accom-

plished through hi-temp sanitization utilizing 180-195°F

fresh water rinse. The unit conveys standard 20” x 20”

dishracks first through a recirculatied (120 GPM) 110 -

140°F prewash and then through a recirculating deter-

gent laden wash section where 270 gallons per minute

(GPM) of 160°F wash water is pumped over the dishrack

to remove the food soil. The rack is then conveyor driven

into a final rinse section where a fresh water final rinse

spray system removes residual detergent and sanitizes.

For hi-temp sanitizing, the unit must be installed to a

potable water line capable of supplying 66 gallons per

hour between 180-195°F at 15-25 PSI flow pressure for

maximum hourly rack capacity of 119 racks per hour.

CONSTRUCTION:

All stainless steel components

are 304 series stainless steel. No 400 series stainless

steel and/or plastics are utilized. Frame is constructed of

2” diameter stainless steel tubing formed and completely

saddle welded for superior strength. The wash tank, and

rinse chamber are formed and heliarc welded 16 gauge

#2B finish. Hood is 16 gauge #3 finish. Stainless steel

feet are adjustable ±1/2”.

PREWASH PUMP:

Internal prewash pump located

inside the prewash tub is totally stainless steel as is the

impeller. T

he prewash pump itself is tot

ally integral with

the motor. prewash water is recirculated from the pre

-

wash tank through the manifolds and prewash arm system

at the rate of 120 G

P

M.

W

AS

H PUMP:

Internal wash pump located inside the

wash tub is tot

ally st

ainless steel as is the impeller. T

he

wash pump itself is totally integral with the motor. Wash

water is recirculated from the wash t

ank through the

manifolds and wash arm system at the rate of 2

7

0 G

P

M.

PR

EW

AS

H PU

M

P MOTOR:

A 1 H

P tot

ally

enclosed, fan cooled type motor drives the wash pump

and arms. Single-phase motors are capacitor st

art,

induction run with internal thermal overload protection.

Three-phase motors are induction run with external over-

load protection. Motor shaft is supported by permanently

lubricated grease pac

ked ball bearings.

W

ASH PUMP MOTOR:

A 2 H

P totally enclosed,

fan cooled type motor drives the wash pump and arms.

Single-phase motors are capacitor start, induction run

with internal thermal overload protection. T

hree-phase

motors are induction run with external overload protec-

tion. Motor shaft is supported by permanently lubricated

grease pac

ked ball bearings.

CONVEY

OR SYSTEM:

R

acks are conveyed

through the machine by a center-mounted, heavy-duty

stainless steel pawl bar with stainless steel cast, counter-

weighted, wide surface pawls. The pawl bar is designed

to not interfere with spray patterns in the wash, and

rinse section. The pawl bar is driven by a 1/4 HP motor

and worm drive gear reduction unit. The conveyor motor

itself is totally enclosed, non-ventilated. Single-phase

motors are capacitor start, induction run with internal

thermal overload protection. Three-phase motors are

induction run with external overload protection. Pawl bar

conveyor drive unit is mounted on the left hand side of

the machine and is enclosed with a removable stainless

steel cover. Maximum conveyor speed is 7.0 feet per

minute for hi-temp machines.

CHAMBER:

The chamber has a standard clearance

of 18”.

CONTROLS:

Controls are located in a stainless steel

control box mounted on top of the machine for ease of

access and increased reliability. Power “ON/OFF” switch

is the only manual switch required. “Energy Guard” fully

automates the machine and utilizes switching logic to

operate wash and rinse sections only when a rack is

being washed or rinsed as well as turning the conveyor

off when a rack exits the machine and there are no other

racks in the machine. Regardless of machine voltage, all

control circuitr

y will be operated from a 1

1

0 volt control

circuit transformer. The unit is completely wired with

105°C, 600V thermoplastic insulated wire and routed

through U

L approved conduit.

FILL:

Initial fill of the prewash tank and wash tank is

automatic when the machine is initially energized. The

prewash tank fill line needs to be hooked up to a 110 -

140°F potable water line; the wash tank fill line needs to

be hooked up to a 180°F minimum potable water line

which normally would be supplied by an external booster

heater or our optional Hatco booster heater packages. Fill

is controlled by standard solenoid valves and vacuum

breaker assemblies. The incoming water solenoids are

activated by stainless steel float systems located in the

tanks for required maintenance of the water levels.

RECIRCULATING PREWASH:

The prewash

tank itself has a 17.25 gallon capacity and maintains the

water level with a separate fill connection from the rest

of the mac

hine. The automatic fill is controlled through

an internal float and an external solenoid valve. Washing

action is accomplished by recirculating water in the pre-

wash t

ank through upper and lower prewash arms. All

prewash arms are easily removable and along with

removable end caps, are easily cleanable without the use

of tools.

R

ECIRCULATING WASH:

T

he wash tank itself

has a 20.4 gallon capacity and maintains that level with

a skimming type overflow. Washing action is accom-

plished by recirculating detergent laden water in the

wash tank through upper and lower wash arms. Make-up

water comes from the final rinse section and is con-

trolled at approximately 2 GPM. The arms themselves are

extended and create a longer wash section than compet-

itive models. Wash section is automatically activated by

racks as they pass through. Wash arms, upper and lower,

contain 36 separate stripping nozzles for superior perfor-

mance. All wash arms are easily removable and along

with removable wash arm end caps, are easily cleanable

without the use of tools. Large stainless steel strainer

pans, as well as a pump intake strainer for secondary

protection are readily accessible and removable for

cleaning purposes. Knockouts and connections are pro-

vided to allow easy installation of detergent concentra-

tion sensor and dispenser tubing by others.

FINAL RINSE:

Fresh pressurized rinse water enters

the machine through a standard “Y” strainer, solenoid

valve, and approved vacuum breaker assembly and is

plumbed to upper and lower final rinse arms located at

the output end of the machine. Single rows of fan jet

nozzles are located on both rinse arms. Connection points

are provided for both rinse agent injection into the final

rinse line by others. Total final rinse flow rate is 3.9 GPM.

DRAIN, OVERFLOW, AND MAKE-UP:

The

machine is designed to maintain appropriate wash tank

water levels at all times even at low pressures. T

he over-

flow system is designed to automatically skim the sur-

face of the wash tank. Make-up water from the final

rinse system not only replenishes the wash water but

also helps maintain appropriate water levels as well as

appropriate wash tank temperatures. A large lever locat-

ed on the front panel of the machine operates a drain

valve and drains the machine completely.

PRESSURE REDUCING VALVE:

Factory

installed on incoming water line to control water pressure.