Additional Standard

Equipment:

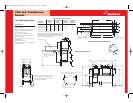

• Vent cowls/splash shields with 4” x 16” openings covered

with removable plates for connection to exhaust ducts

when required.

• Flexible strip curtains provided at the ends of the

vent cowls as well as at the ends of the machine and

separating the prewash, wash, power rinse, and final

rinse sections.

• Extra large inspection doors located on front of

machine for easy access and cleanability.

• Safety door switches shut down machine should any

door be opened during operation.

• Stainless steel front appearance panel.

• Positive low level water protection for wash and power

rinse tank heat.

• Sealed dial type thermometers for the wash and final

rinse temperatures.

Optional Mandatory

Specifications:

WASH TANK HEATING EQUIPMENT

(Choose One):

ELECTRIC:

Low watt density 15 KW tubular heating

elements mounted inside the wash tank and easily

removable from the outside. The heaters are protected

by a stainless steel float system as well as high limit

overload protection. Water temperature in the tanks is

controlled and maintained by fast reacting thermostats

whic

h control the heating elements.

STEAM:

St

ainless steel coils are utilized rather than

injectors so that cont

aminated steam being injected into

the wash water is not an issue. Stainless steel tubular

steam coils are mounted inside the wash and power

rinse t

ank

s below the optimum water level. T

he coils are

protected by a stainless steel float system. An external

steam “Y” strainer and high temperature steam solenoid

regulates the flow of steam through the coils.

Temperature in the tanks is controlled and maintained by

fast reacting thermost

ats which control the operation of

the steam solenoids. A float and thermost

atic steam trap

is provided and removes steam condensate from the

steam coils whic

h can either be plumbed to a drain or

pumped bac

k to the boiler if a condensate return system

is available. Steam coils require a minimum of 10 PSIG

flowing steam supply and a ma

ximum of 20 PSIG. Install

with a steam pressure regulator (by others) if steam

supply exceeds 20 PSIG.

Optional Features and

Accessories:

EXTERNAL 40°F ELECTRIC BOOSTER

H

EATER:

External 7 K

W booster heater boosts incom-

ing 140°F water to a minimum of 180°F for hi-temp san-

itizing rinse. Custom features include castone-lined tank,

low water cutoff, pressure relief valve, as well as a pres

-

sure reducing valve. Unit is located next to the output

end of the machine, completely preplumbed. Power to

the booster heater requires a separate electrical connec

-

tion. Unless specified otherwise, electrical characteristics

of the booster heater will be the same as that of the

dishwasher. The booster heater is available in

20

8/240/480 voltages/3 phase only.

E

XTERNAL 70°F RISE BOOSTER HEATER:

External 12 KW booster heater capable of boosting

incoming 110°F water a minimum of 70 degrees to a min-

imum of 180°F for hi-temp sanitizing rinse. Unit is located

next to the output end of the machine and comes com-

pletely preplumbed. Power to the booster heater requires

a separate electrical connection. Unless specified other-

wise, electrical characteristics of the booster heater will

be the same as that of the dishwasher. The booster

heater is available in 208/240/480 voltages/3 phase only.

STEAM BOOSTER HEATER:

Sized to be con-

nected to a standard 110°F incoming water supply in

order to insure 180-195°F hi-temp sanitizing final rinse

requirements. Unit comes complete with steam “Y”

strainer and high temperature steam solenoid as well as a

steam pressure relief valve. Water temperature is con-

trolled and maintained by a fast reacting thermostat

which controls the operation of the steam solenoid. A float

and thermost

atic steam trap is provided and removes

steam condensate from the coil whic

h can either be

plumbed to a drain or pumped back to a boiler if a con-

densate return system is available. Must be inst

alled with

a steam pressure regulator (by others) if steam supply

exceeds 20 PSIG.

TABLE LIMIT SWITCH:

Factory wired to machine

and mounted to the bac

k

splash of the table in the field.

P

revents damage to conveyor drive system, rac

k

s, and

dishes due to racks backing up on the output end of the

mac

hine. Highly recommended for clean dishtables less

than 1

0 feet in length.

VE

NT CO

WL COLLAR

S:

F

actor

y inst

alled 4” x 1

6”

x 7” high collars located on the vent cowls to allow easy

connection to an external exhaust system including a st

an-

dard “pant-leg” t

ype exhaust duct. Includes adjust

able and

lockable damper flap for fine tuning exhaust system to

remove appropriate C

FM requirements.

50 CYCLE (HERTZ) ELECTRICAL

CHARA

CTERISTICS:

Units are available in 5

0 HZ

in the following voltages: 208V/1 or 3PH, 230V/1 or 3PH,

380V/3PH, and 460V/3PH. Units operating at 50 HZ are

not submitted for U

L Listing.

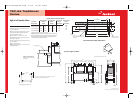

S

IDELOADER:

F

actory installed option on input end

of conveyor machine. This feature allows the machine to

be installed close to a corner and maximize dishroom

space. T

he sideloader option is available in both the

hooded and unhooded versions. See separate spec sheets

for details.

EXHAUST VENT FAN CONTROL:

Automatically turns exhaust vent fan on when rack

enters the machine. Delay timer also turns off the

exhaust vent fan 5-10 seconds after rack exits machine

when no other racks are being conveyed through the

machine.

FLANGED FEET:

Available for installations where

permanent mounting to the floor is required. Fully

adjustable for required height.

WATER HAMMER ARRESTOR:

Installed

inside the supply line.