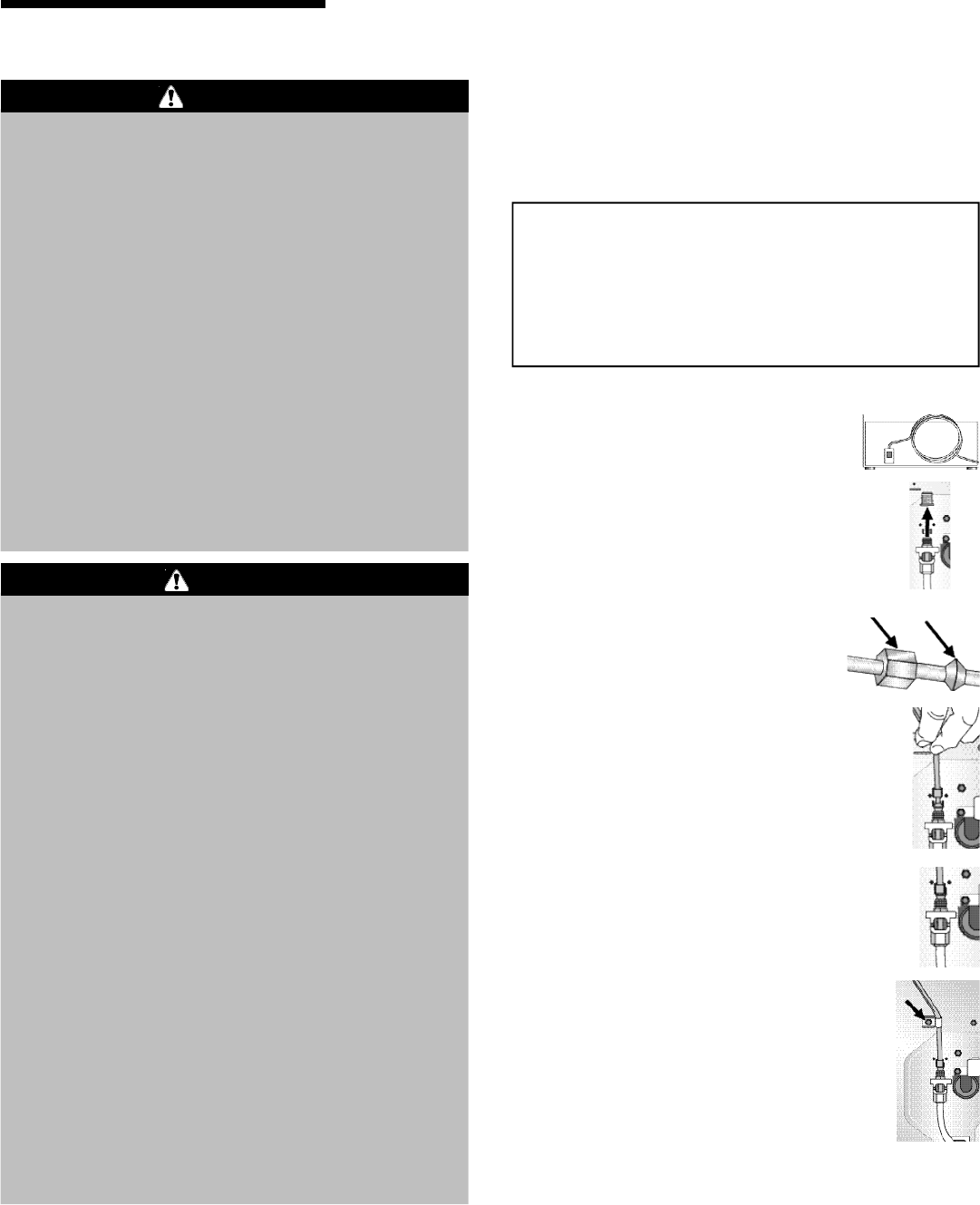

5. Slide brass nut over sleeve and screw nut

into inlet port. Tighten nut with wrench.

IMPORTANT: Do not overtighten. Cross

threading may occur.

6. Pull on tubing to confirm connection is

secure. Connect tubing to frame with

water tubing clamp (C) and turn on

water supply. Check for leaks and

correct if necessary. Continue to

observe the water supply connection

for two to three hours prior to moving

the refrigerator to its permanent

location.

7. Monitor water connection for 24 hours. Correct

leaks, if necessary.

Connecting the Water Supply

To reduce the risk of injury or death, follow

basic precautions, including the following:

• Read all instructions before installing ice maker.

• Do not attempt installation if instructions are not

understood or if they are beyond personal skill

level.

• Observe all local codes and ordinances.

• Do not service ice maker unless specifically

recommended in Use & Care Guide or published

user-repair instructions.

• Disconnect power to refrigerator before installing

ice maker.

• Water damage due to an improper water

connection may cause mold/mildew growth. Clean

up spills or leakage immediately!

WARNING

To avoid property damage or possible injury,

follow basic precautions, including the

following:

• Consult a plumber to connect

1

⁄

4

” O.D. copper

tubing to household plumbing to assure

compliance with local codes and ordinances.

• Confirm water pressure to water valve is between

35 and 100 pounds per square inch, 20 pounds

per square inch without filter.

• Do not use a self-piercing, or

3

⁄

16

” saddle valve.

Both reduce water flow and can become clogged

over time, and may cause leaks if repair is

attempted.

• Tighten nuts by hand to prevent cross threading.

Finish tightening nuts with pliers and wrenches.

Do not overtighten.

• Wait two to three hours before placing refrigerator

into final position to check and correct any water

leaks. Recheck for leaks after 24 hours.

• Verify the copper tubing under the sleeve is

smooth and free from defects. Do not reuse an old

sleeve.

CAUTION

9

I

NSTALLATION

Materials Needed:

•

1

⁄

4

” outer diameter flexible copper tubing

• Shut-off valve (requires a

1

⁄

4

” hole to be drilled into

water supply line before valve attachment)

• Adjustable wrench

•

1

⁄

4

” hex nut driver

Notes

• Use copper tubing only for installation. Plastic is

less durable and can cause damage.

• Add 8’ to tubing length needed to reach water

supply for creation of service loop.

1. Create service loop with copper

tubing (minimum 2’ diameter).

Avoid kinks in the copper tubing

when bending it into a service

loop. Do not use plastic tubing.

2. Remove plastic cap from water valve inlet

port.

3. Place brass nut (A) and sleeve (B)

on copper tube end as illustrated.

Reminder: Do not use an old

sleeve. The nut and sleeve are

provided in the use and care packet.

4. Place end of copper tubing into water

valve inlet port. Shape tubing slightly. Do

not kink – so that tubing feeds straight

into inlet port.

A

B

2’ diameter

minimum

C

12828119 Jenn-Air Trio Eng 1/14/05 8:53 AM Page 10