6

Important Installation Suggestions

1. Chamfer all exposed edges of decorative l aminate to

prevent damage from chipping.

2. Radius corners of cutout and file to insure smooth

edges and prevent corner cracking.

3. Rough edges, inside corners which have not been

rounded and forced fits can contribute to cracking of the

countertop laminate.

4. Countertop must be s upported within 3² of cutout.

On any bur ner, closing the air shutter too far will

cause the flame to become soft and yellow tipped.

Opening the a ir shutter too wide will c ause the flame

to blow away from the burner ports. Proper adjustment

will produce a sharp, clearly defined, even blue flame.

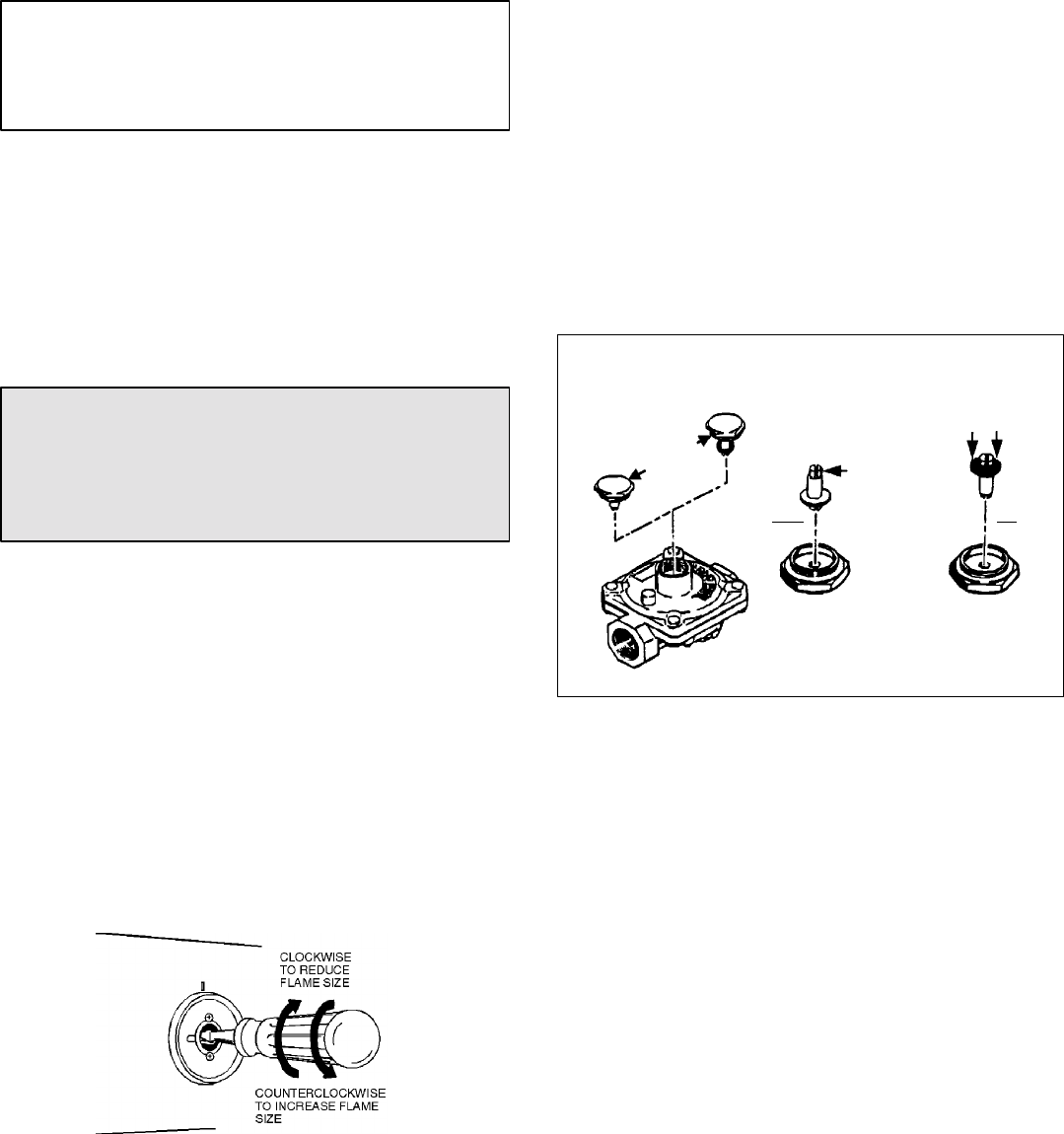

Low Flame Adjustment

(See Illustration “C”)

This appliance i s shipped from the factory with low and

medium flame settings adjusted for use with Natural Gas.

If further adjustment is necessary, or to re-adjust for use

with LP, proceed as follows:

1. Light burner and set control knob for low flame.

2. Remove c ontrol knob from valve stem.

CAUTION: NEVER USE A METAL BLADE TO PRY

KNOB OFF. IF KNOB CANNOT BE EASILY

REMOVED, TUCK THE FOLDS OF A C LOTH

DISHTOWEL UNDER THE KNOB AND PULL THE

TOW EL UPWARD WITH STEADY, EVEN PRES-

SURE.

3. Insert a slender, thin-blade screwdriver into the r ecess

at center of valve s tem and engage blade with slot in

adjusting screw.

4. Turn center stem adjusting screw to set flame size.

...clockwisetoreduce.

...counterclockwise to increase.

5. Replace control knob when adjustment is completed.

Proper adjustment will produce a stable, steady blue flame

of minimum size. The final adjus tment should b e checked

by turning knob from high to low several times without

extinguishing the flame.

This adjustment, at low setting, will automatically provide

the proper flame size at medium setting.

Pressure Testing

The maximum gas supply pressure for the appliance

pressure regulator supplied on this appliance is 1 4² W.C.

The test pressure for c hecking this applianc e pressure

regulator must be at least 6² W.C. for Natural Gas, and at

least 11² W.C. for LP. It is shipped from the factory set for

Natural Gas at 5 ² W.C.

This appliance and its individual shutoff valve m ust be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2² PSIG (3.5 k Pa).

This appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2² PSIG

(3.5 k Pa).

Appliance Pressure Regulator

Conversion

(See Illustration “D”)

This unit is supplied with a Maxitrol Appliance Pressure

Regulator. Follow the instructions in illustration “ D”.

Illustration “D”

NAT

LP

CONVERTER

CAP

AND PIN

MAXITROL APPLIANCE PRESSURE REGULATOR

NAT LP

APPLY

SIDEWARD

FINGER

PRESSURE TO

REMOVE PIN

FROM CAP

APPLY DOWNWARD

FINGER PRESSURE

AT DISC EDGES TO

REPLACE PIN IN CAP

Illustration “C”