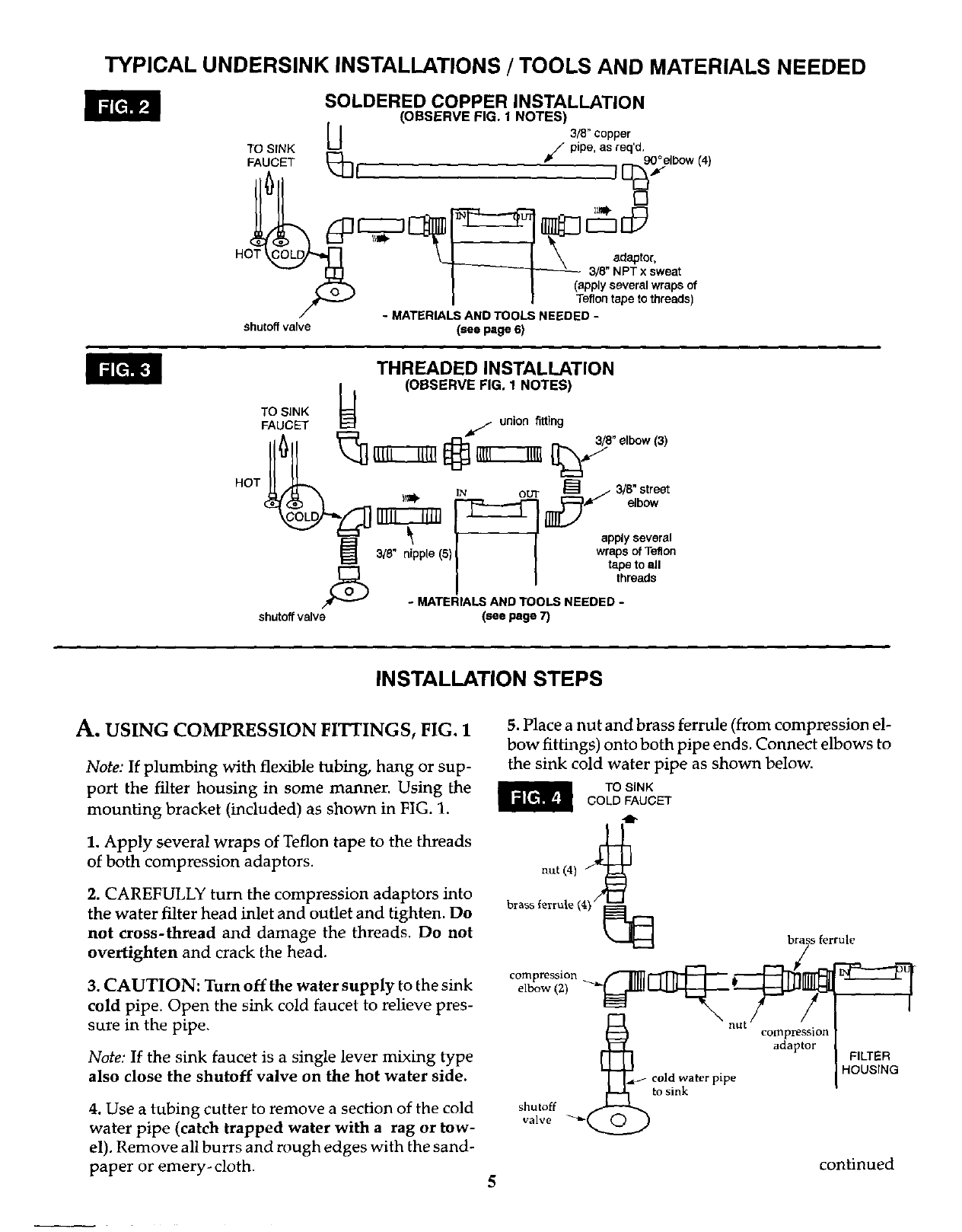

TYPICAL UNDERSINK INSTALLATIONS / TOOLS AND MATERIALS NEEDED

SOLDERED COPPER INSTALLATION

(OBSERVE FIG. 1 NOTES)

3/8" copper

TO S,NK LJ / pipe. as req'd.

FAUCET _. __ 90°elbow (4)

.oWo -LL_ l\ °0ap,e ,

-- .F_ I _-_--"_(e;_Sy"_NvPeTr axlS'Wae;ts°f

F .MA,ER,A'S , g;,_oo,ape,o,h eads,

shutoffvalve (see page 6)

THREADED INSTALLATION

I } (OBSERVE FIG, 1 NOTES)

TO S NK I_l

FAUCET _ _,- union fitting

HOT H rL_

J__ Ilmk IN or.rr _ / 3/8" street

__[] _ w_PaP'sYoS_;ee_a'n

] 3(8" nipple (5) I I P

r_l I ] tape to ell

I I threads

- MATERIALS AND TOOLS NEEDED -

shutoff valve (see page 7)

INSTALLATION STEPS

A. USING COMPRESSION FITTINGS, FIG, 1

Note: If plumbing with flexible tubing, hang or sup-

port the filter housing in some manner. Using the

mounting bracket (included) as shown in FIG. 1.

1. Apply several wraps of Teflon tape to the threads

of both compression adaptors.

2. CAREFULLY turn the compression adaptors into

the water filter head inlet and outlet and tighten. Do

not cross-thread and damage the threads. Do not

overtighten and crack the head.

3. CAUTION: Turn offthe water supply to the sink

cold pipe. Open the sink cold faucet to relieve pres-

sure in the pipe,

Note: If the sink faucet is a single lever mixing type

also close the shutoff valve on the hot water side.

4. Use a tubing cutter to remove a section of the cold

water pipe (catch trapped water with a rag or tow-

el), Remove all burrs and rough edges with the sand-

paper or emery-cloth.

5. Place a nut and brass ferrule (from compression el-

bow fittings) onto both pipe ends, Connect elbows to

the sink cold water pipe as shown below.

TO SINK

COLD FAUCET

nut (4) ,_

brass ferrule (4)

[_f co d p'p

-_ to sink

brass ferrule

FILTER

HOUSING

5

continued