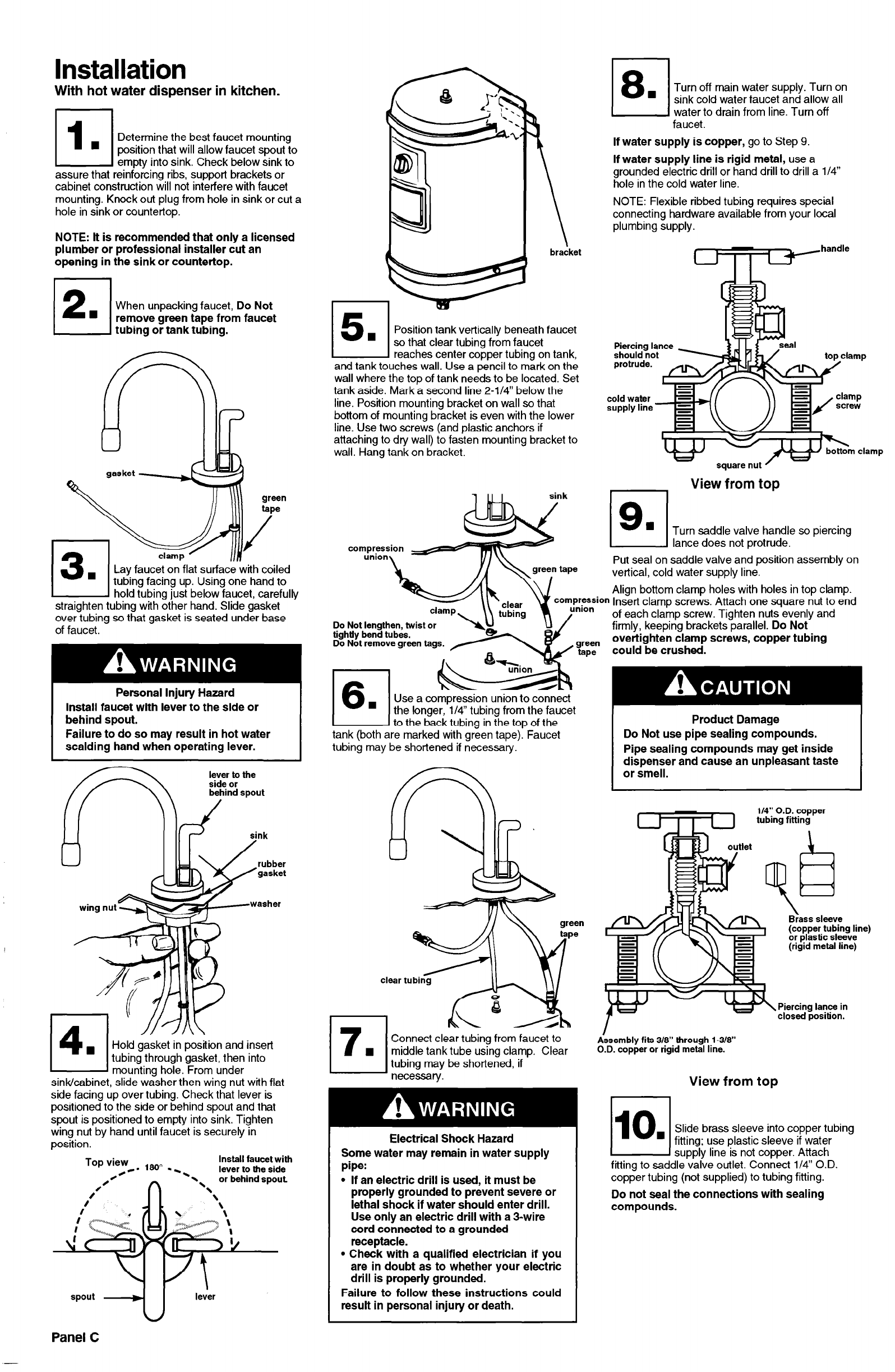

Installation

Turn off main water supply. Turn on

sink cold water faucet and allow all

water to drain from line. Turn off

With hot water dispenser in kitchen.

I

1

Determine the best faucet mounting

position that will allow faucet spout to

empty into sink. Check below sink to

assure that reinforcing ribs, support brackets or

cabinet construction will not interfere with faucet

mounting. Knock out plug from hole in sink or cut a

hole in sink or countertop.

faucet.

If water supply is copper, go to Step 9.

If water supply line is rigid metal, use a

grounded electric drill or hand drill to drill a l/4”

hole in the cold water line.

NOTE: Flexible ribbed tubing requires special

connecting hardware available from your local

plumbing supply.

NOTE: It is recommended that only a licensed

plumber or professional installer cut an

opening in the sink or countertop.

I

bracket

When unpacking faucet, Do Not

remove ureen tape from faucet

1

I

Position tank vertically beneath faucet

so that clear tubina from faucet

j j tubing oFtank tubing.

u reaches center cobper tubing on tank,

and tank touches wall. Use a pencil to mark on the

wall where the top of tank needs to be located. Set

tank aside. Mark a second line 2-l/4” below the

line. Position mounting bracket on wall so that

bottom of mounting bracket is even with the lower

line. Use two screws (and plastic anchors if

attaching to dry wall) to fasten mounting bracket to

wall. Hang tank on bracket.

I

View from top

W’

green

We

19 I

n

Turn saddle valve handle so piercing

u lance does not protrude.

Lay faucet on flat surface with coiled

tubing facing up. Using one hand to

hold tubinn iust below faucet, carefullv

compression

union\ T

Put seal on saddle valve and position assembly on

vertical, cold water supply line.

Align bottom clamp holes with holes in top clamp.

compression

Insert clamp screws. Attach one square nut to end

of each clamo screw. Tiahten nuts evenlv and

straighten tubing with other hand. Slide gasket z

over tubing so that gasket is seated under base

of faucet.

DO Not lengthen, twist or

tightly bend tubes.

Do Not remove green tags.

firmlv, keep& bracketstarallel. Do Not-

ovet%ghtdn clamp screws, copper tubing

could be crushed.

Install faucet with lever to the side or

Failure to do so may result in hot water

scalding hand when operating lever.

I

Use a compression union to connect

the longer, l/4” tubing from the faucet

Do Not use pipe sealing compounds.

Pipe sealing compounds may get inside

Product Damage

dispenser and cause an unpleasant taste

or smell.

I

tank (both are marked with green tape): Faucet

tubing may be shortened if necessary.

to the back tubina in the top of the

lever to the

side or

behind spout

f#

sjnk

J .

outlet

green

We

n

7

7 clear tubing fl

Connect clear tubing from faucet to

H

middle tank tube using clamp. Clear

tubing may be shortened, if

necessary.

-

4

Piercing lance in

closed position.

- \’ // IIt-

Assembly fits 318” through l-318”

O.D. copper or rigid metal line.

Hold gasket in position and insert

tubing through gasket, then into

mountina hole. From under

View from top

sink/cabinet, slide w&her then wing nut with flat

side facing up over tubing. Check that lever is

positioned to the side or behind spout and that

spout is positioned to empty into sink. Tighten

wing nut by hand until faucet is securely in

position.

Top view

Install faucet with

)-. 180” .-

lever to the side

0

0

0

n

.N

\

or behind spout

0

\

\

I .

\

spout

Panel C

lever

Slide brass sleeve into copper tubing

fitting; use plastic sleeve if water

Electrical Shock Hazard

Some water may remain in water supply

pipe:

l If an electric drill is used, it must be

properly grounded to prevent severe or

lethal shock if water should enter drill.

Use only an electric drill with a 3-wire

cord connected to a grounded

receptacle.

l Check with a qualified electrician if you

are in doubt as to whether your electric

drill is properly grounded.

Failure to follow these instructions could

result in personal injury or death.

u sup&y line-is not copper. Attach

fitting to saddle valve outlet. Connect l/4” O.D.

copper tubing (not supplied) to tubing fitting.

Do not seal the connections with sealing

compounds.