Impinger I -–1000 Series Service Manual - Domestic

22

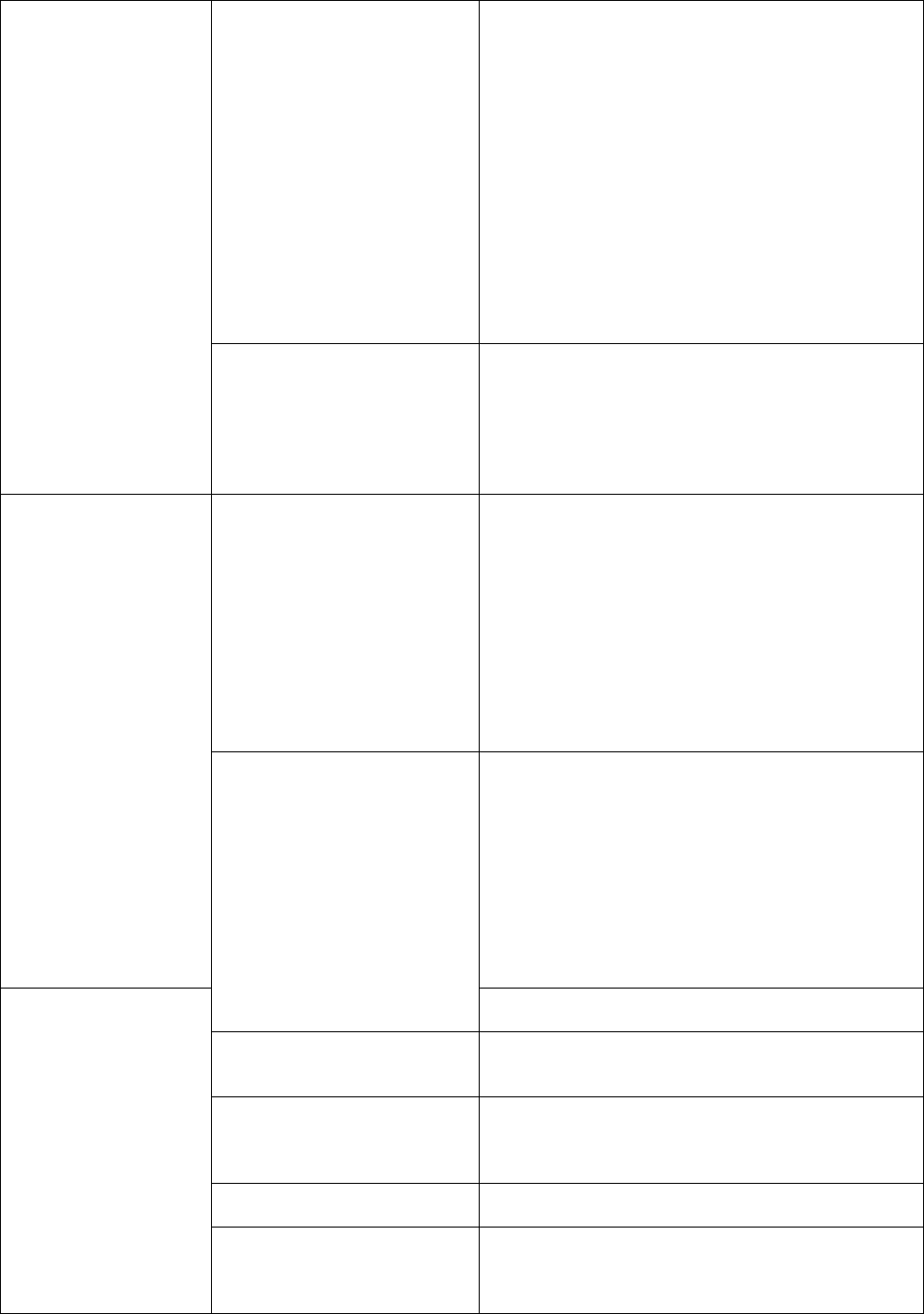

Flame Sensor (There should be a visible pilot flame at this time.)

To check for proper flame sensor operation,

connect a digital multimeter (capable of measuring

D. C. microamperes) in series between the flame

sensor wire (normally connected to terminal #4)

and terminal #4. NOTE: This is a current

measurement and the meter must be connected in

series. This procedure is for checking the pilot

flame only. Remove main valve wire (Red) from

terminal #3 on ignition control. With a visible pilot

flame, the current readings should be as follows:

Johnson G-65 control, 0.2 micro amp. D.C.

minimum/Johnson G-60 control, 0.7 micro amp.

D.C. minimum. If these values are not achieved,

replace flame sensor. Also check for any type of

damage to flame sensor wire and connections.

Pilot flame but no main

flame

Ignition Control and Valve

Assembly

If there is a pilot flame, and there is sufficient micro

amp. current at terminal #4, check for 24 VAC

that the main valve (internal to valve assembly) has

opened. Connect a manometer to the manifold gas

pressure tap located on the back side of the ignition

control and valve assembly. If no gas is present,

replace ignition control and valve assembly.

Centrifugal Switch of Burner

Blower Motor

NOTE:

Check for 24 VAC output from secondary of

transformer. If voltage is present, check for 24 VAC

at terminals marked "24V" and "24V gnd" on

Ignition Control. If the Burner Blower Motor is

running and there is no voltage at terminals 24V

and 24V gnd on the ignition control, replace the

Burner Blower Motor.

These Ignition Controls have a 30 second pre-

purge(Delay) and a 15 second lock-out time – The

Ignition Control will try for ignition for 15 seconds

and then shut-off. To Re-try for ignition, turn off

burner switch, wait 30 seconds and re-try ignition.

For ovens with

Honeywell ignition

control

Check for 24 VAC supply to ignition control at

terminals "24V" and "24V gnd". If voltage is

present, check for 24V at terminal "P.V. (Pilot

Valve) and "gnd". If voltage is not present, replace

Ignition Control. If the pilot valve is energized,

check to see that the high voltage ignitor circuit is

also energized. To check, disconnect the ignitor

lead from the ignition control. Place the terminal of

ignitor lead approximately 1/8" from terminal post

on Ignition Control. Spark should jump the 1/8"

gap. If no spark is present, replace ignition control.

Ignition Control

If the ignition control is supplied with 24 VAC and

the pilot valve (in gas valve) and ignitor circuits

Pilot Shut-off Valve If no pilot flame is visible, check to see that the pilot

shut-off valve is open(shut-off valve is located

between gas valve and burner).

Pilot Tube Check for gas pressure at pilot tube. Disconnect

pilot tube at burner and connect manometer to pilot

tube. If no gas pressure is present, check for

blockage in pilot tube or pilot shut-off valve.

Pilot Orifice If there is gas pressure at the pilot tube, check the

pilot orifice for obstructions. Replace as needed.

No Pilot

Burner Ignitor Check the burner ignitor head for any obstructions,

also check for frayed or broken wire, any type of

damage to spark gap (.100 in. 2.5 mm) If there is

visible damage, replace ignitor assembly.