Impinger X2 – Analog Service Manual – Dom & Int’l 15

switch as needed.

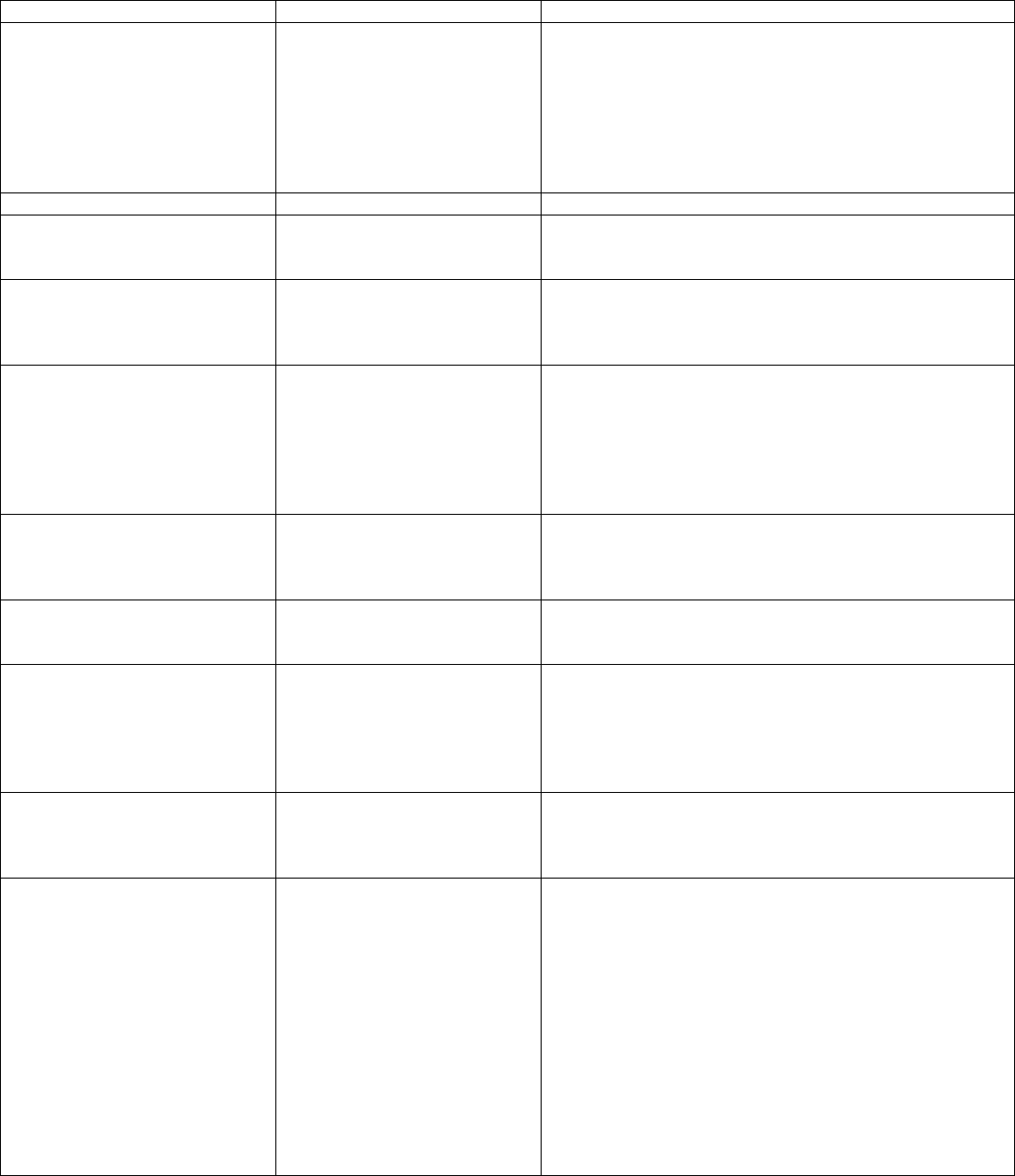

Control, conveyor Check for supply voltage to conveyor control at

terminals #1 (AC) and #2 (AC). If no voltage is present,

trace wiring back to conveyor switch. If AC voltage is

present, check for DC voltage output at terminals #3

(A-) and #4 (A+). If there is AC voltage in, but no DC

voltage out of the conveyor control. Replace the

conveyor control. If there is D.C. voltage output,

proceed.

Fuse, 2 Amp Check, replace if necessary.

Fuse holder Check for D.C. voltage supplied to fuse holder. If no

voltage is present, trace wiring back to conveyor

control. Check fuse holder, replace if necessary.

Switch, conveyor reversing Check for D.C. voltage supplied to the reversing switch.

If no voltage is present, trace wiring back to the fuse

holder. Check continuity between switch terminals.

Replace switch as needed.

Conveyor motor Check for D.C. voltage to the conveyor motor. If no

voltage is present, trace wiring back to the reversing

switch. If voltage is present and the motor will not run,

check the motor windings for opens or shorts. Check

motor brushes for excessive wear. Replace motor

brushes as needed.

If any of the above fails, replace conveyor motor.

Conveyor Check for any mechanical problems in the conveyor

assembly. Check for damaged or torn belting. Check

conveyor shaft bearings for damage or excessive wear.

Repair or replace conveyor components as needed.

Conveyor speed varying or

intermittent

Power supply Check for a steady supply voltage to the conveyor

control. If voltage is not steady, trace back to power

supply.

Control, conveyor Check for a steady DC voltage output at terminals A+

and A-. If voltage is not steady, proceed. Check for

5 VDC output from the conveyor control at terminals

+5V(red) and COM (black). If there is no voltage output,

replace the conveyor control. If there is DC output,

proceed.

Motor, conveyor Check conveyor motor and gearbox for any visible

damage. If there is apparent damage, repair or replace

conveyor motor. Check motor brushes for excessive or

abnormal wear. Replace motor brushes as needed.

Hall effect sensor/magnet Check to be sure that the Hall effect sensor and

magnet are mounted on the motor. Check for any

visible damage to the Hall effect sensor and magnet. If

there is visible damage, repair or replace as needed. If

there is no visible damage, check for a frequency

output from the hall effect sensor at terminals SIG

(white) and COM (black).

Readings should be as follows:

2:15 cook time 56 Hz. approx.

5:00 25 Hz. approx.

10:00 13 Hz. approx.

16:00 8 Hz. approx.

If these readings are not achieved, replace the Hall

effect sensor/magnet