Impinger X2 – Analog Service Manual – Dom & Int’l 7

bearings. Replace bearings as needed.

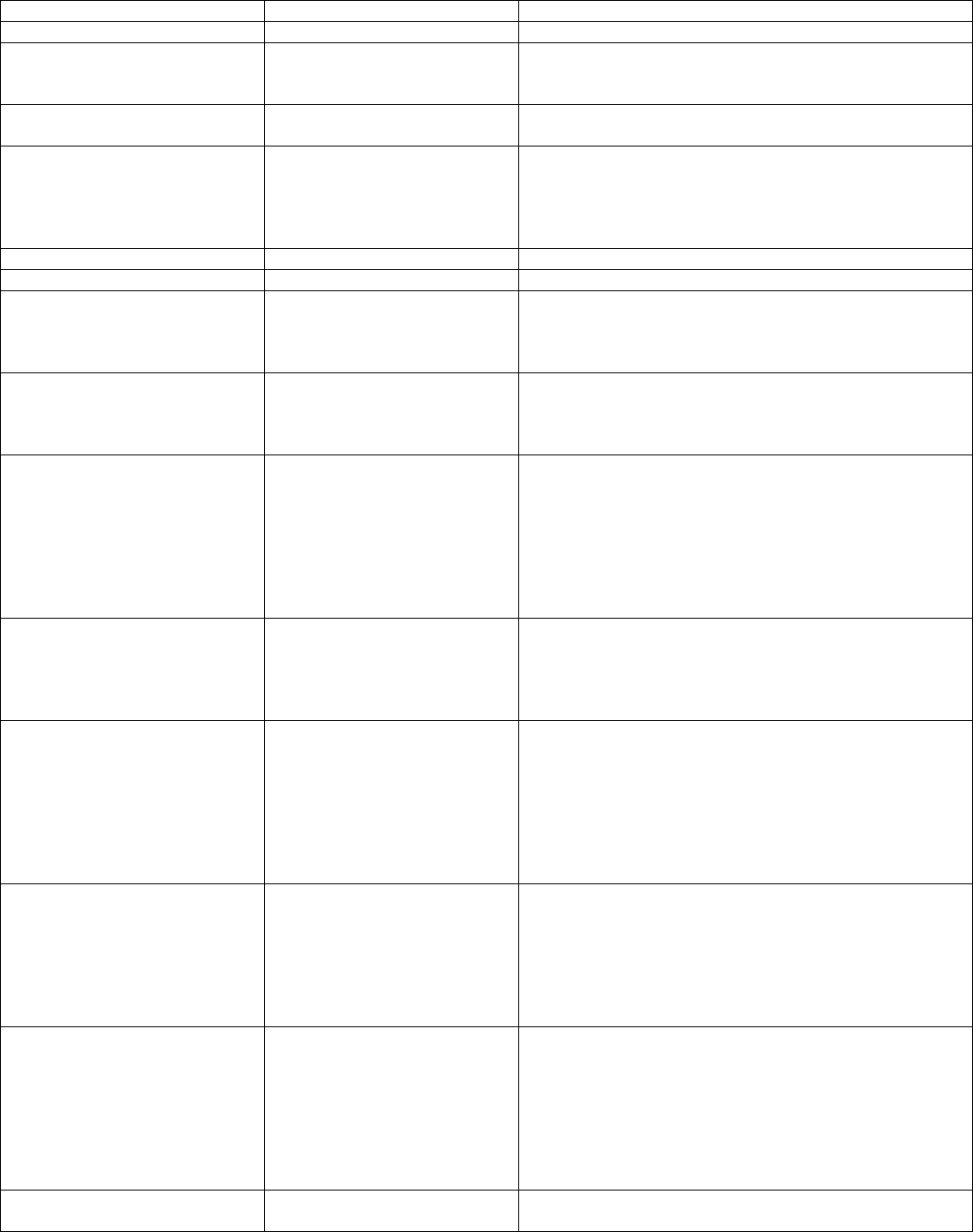

Oven will not heat Gas supply Check for adequate gas supply to oven.

Manual gas shut off valve Check to see that the manual gas shut off valve is

open. Also, check flexible gas line connection for any

damage.

Main fan motor Check for main fan operation. If it is not operating, refer

to “Oven fan will not run”.

Relay, main fan Check for 120VAC supplied to relay terminal #13. If

voltage is not present, trace wiring back to power

supply. If voltage is present, check for 120VAC at

terminal #14. If there is no voltage at terminal #14, and

the relay is energized, replace the main fan relay.

Fuse, 2 Amp, control (F8) Check, replace if necessary.

Fuse holder Check, replace if necessary.

Switch, oven fan Check for 120VAC to the switch, if no voltage is

present, trace wiring back to the main fan relay. Check

continuity between switch terminals. Replace switch as

needed.

Switch, burner Check for 120VAC to the switch, if no voltage is

present, trace wiring back to the oven fan switch.

Check continuity between switch terminals. Replace

switch as needed.

Air pressure switch Check for 120VAC to the air pressure switch. If no

voltage is present, trace wiring back to burner switch.

This normally open switch should close when the main

fan is activated. Check air switch tube for blockage or

any obstructions, repair as needed. Refer to the

“Removal and installation” section for proper

adjustment of air pressure switch. Replace air pressure

switch as needed.

Transformer, burner Check for 120VAC supplied to primary of transformer. If

no voltage is present, trace wiring back to the air

pressure switch. If voltage is present, check for 24VAC

at transformer secondary. If there is primary voltage but

no secondary voltage, replace burner transformer.

Relay, burner blower Check for 24VAC supply to relay coil. If no voltage is

present, trace wiring back to burner transformer. Check

for 120VAC to relay contact. If no voltage is present,

trace wiring back to air pressure switch. When 24VAC

is applied to the coil, there will be a delay of 20 – 30

seconds. After this time delay, the relay contacts

should close. If there is 24VAC applied, but the

contacts do not close, replace the burner blower relay.

Motor, burner blower Check for 120VAC supplied to the burner blower motor.

If no voltage is present, trace wiring back to the burner

blower relay. If voltage is present, and the motor is not

turning, check for opens, shorts or grounds.

WITH POWER OFF: Check for locked rotor.

Replace burner blower motor as needed.

Centrifugal switch of

Burner blower motor

Check for 24VAC supplied to centrifugal switch at wire

S5. If no voltage is present, trace wiring back to the

burner transformer. If voltage is present, check for

24VAC out of centrifugal switch at wire #32. If there is

voltage in, but there is no voltage out, and the burner

blower motor is running, replace the burner blower

motor.

Burner control Check for 24VAC supplied to the burner control at

terminals #5 and #6. If no voltage is present, trace