12

ENGLISH

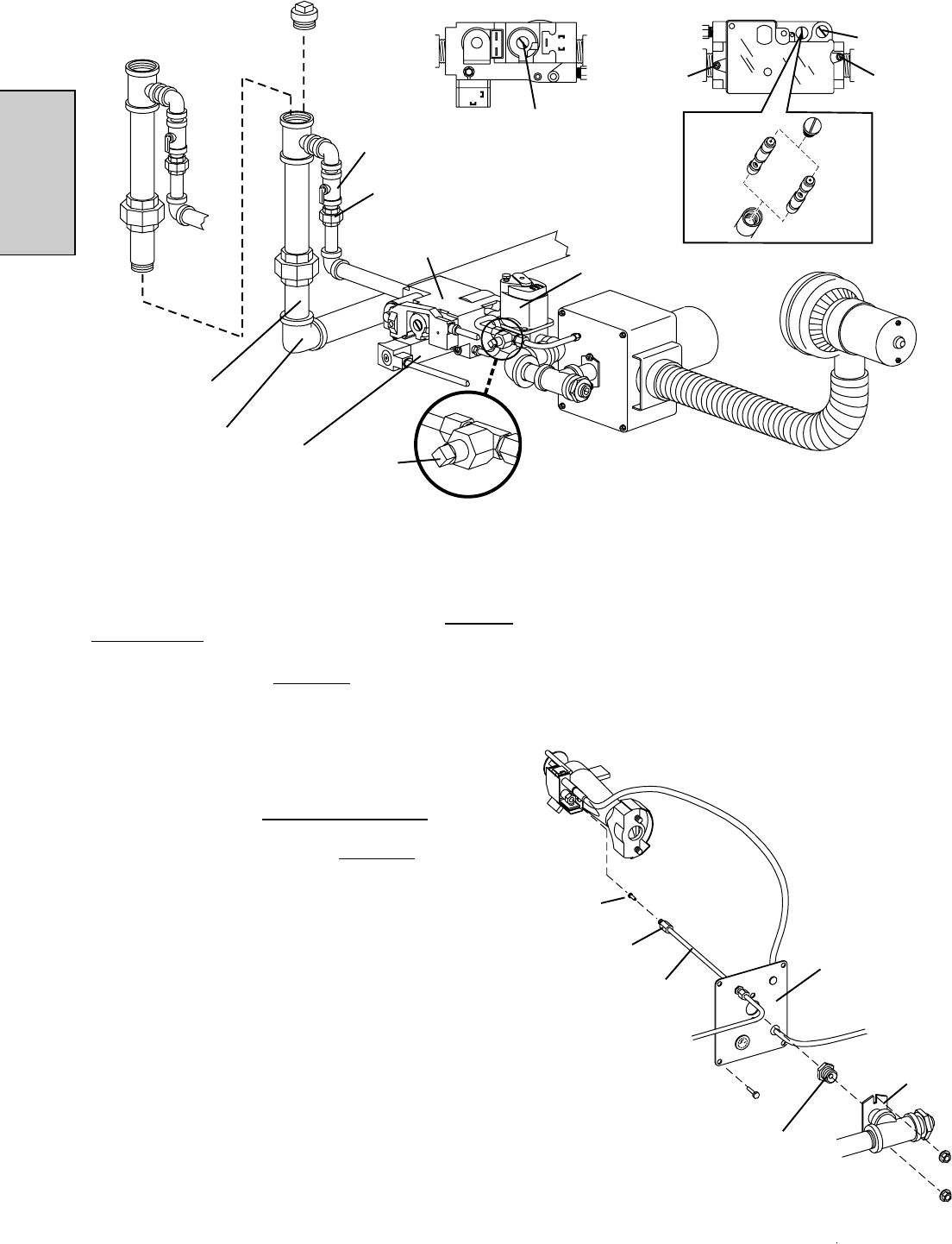

B. Preparation for Use with Various Gases

Before proceeding to set up the oven for a specific gas, check

that the main gas supply valve and the circuit breaker/fused

disconnect are in the OFF ("O") position.

The main and pilot orifices must match the sizes shown in Table

1-5. If necessary, replace the orifices. Refer to Part C,

Replacing

the Gas Orifices.

The orifice (manifold) pressure should be adjusted to the value

shown in Table 1-5 (in the

Description section) for the specific

gas type and location.

1. For Use with Natural Gas

The actual heat input to the oven must match the rated heat

input. The input to the burner can be determined using the

orifice (manifold) pressure data or by the volume supplied

using the gas meter. Both of these procedures are

described in Part E,

Checking the Heat Input.

If the measured input does not correspond with the rated

input (shown in Table 1-5 in the

Description section of this

Manual), check first that the correct orifices are installed. If

the orifices are correct, check and correct the supply and

orifice pressures to obtain the correct input based on the

gas meter reading.

2. For Use with Liquid Propane (LP) Gas

When using liquid gas with an oven equipped with a Type

2 gas control valve (see Figure 2-16), the converter in the

multifunction gas valve must be removed, and then replaced

INVERTED from its former position. Inverting the converter

will disable the governor. This step is only required if the

supply pressure is below 50mbar.

C. Replacing the Gas Orifices (if so required)

1. Replacing the Main Orifice

a. Check that the main gas supply valve and the circuit

breaker/fused disconnect are in the OFF ("O") position.

b. Open the 1/2" union in the gas supply line. The union

is located between the oven's manual shutoff valve

and the multifunction gas valve. See Figure 2-16.

c. Refer to Figure 2-17. Unscrew the four hex screws that

hold the venturi mounting plate to the front of the

burner. Remove the gas train/venturi assembly from

the oven.

d. Remove the two 1/2" nuts that secure the gas train to

the venturi mounting plate.

e. Remove the main orifice using an 11/16" wrench.

f. Install the new orifice by following the above procedure

in reverse order.

Figure 2-17 - Replacing the Main and Pilot Orifices

Main

orifice

Pilot

orifice

Pilot tube

Compression

nut

Main orifice

holder (attached

to gas train)

1/2" hex nuts

Venturi

assembly

Venturi

mounting

plate

Ignition

sensor

wire

Modulating

gas valve

Pilot

pressure

tap

Gas Control

Valve

(see inset)

Gas Burner

Burner

Blower

Supply (inlet)

pressure tap

Manual

shutoff

valve

Gas line for

other oven

cavities

Cap for

top oven

cavity

Elbow, 90°,

1-1/4 dia.

Orifice (manifold)

pressure tap

Nipple, 1-1/4"

dia. X 3"

(76mm) L, NPT

1/2" union

Figure 2-16 - Gas Burner

and Piping Assembly

SECTION 2 - INSTALLATION

Gas

pressure

switch

Governor

enabled for

natural gas

operation

Governor

disabled for

liquid

propane

operation

Manifold pressure

adjustment (under

cap screw)

Manifold pressure

adjustment

Type 1 Gas Control Valve Type 2 Gas Control Valve