SECTION 4

MAINTENANCE

43

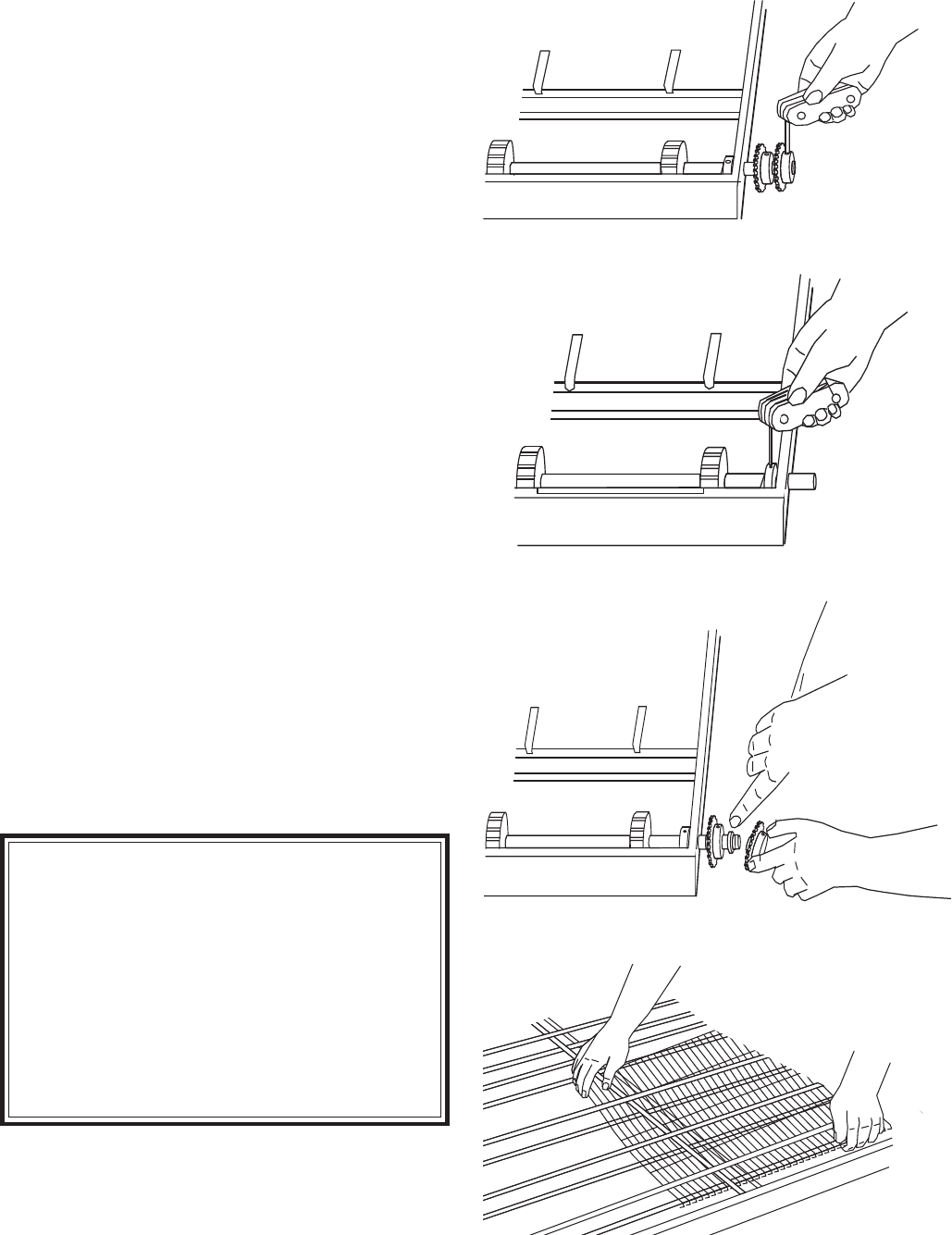

12. Slide shaft assembly to right side, holding assembly

in place. Slide split locking collar to the left side and

tighten.

13. Slide rear conveyor drive sprocket onto shaft. Tighten

the set screw of this drive sprocket until it extends into the

hole of the hollow shaft. It should NOT touch the inner,

solid shaft. Check to see that only the rear shaft moves

when the sprocket is turned. If both shafts move, you have

tightened the set screw too tight. Loosen the set screw

until only the rear shaft moves when the sprocket is

turning.

14. Insert adaptor bushing into remaining drive sprocket

then place onto shaft. Make sure nylon spacer is in place.

Tighten set screw making sure screw goes through slot in

adaptor bushing and locks onto shaft.

15. Thread conveyor belts back onto frame making sure

the links will be traveling in the proper direction.

16. Follow conveyor reassembly instructions in Monthly

Maintenance Paragraph “F”.

NOTE: It is recommended that the 6 Month Maintenance

schedule be performed by a Middleby Marshall authorized

service technician.

IV. MAINTENANCE - EVERY 6 MONTHS

A. Check brushes on D.C. conveyor motor, when worn to

less than 1/10″ (2.4mm), replace the brushes.

B. Clean and inspect the burner nozzle and electrode

assembly. Also check your oven venting system.

C. Check conveyor shaft bushings and spacers. Replace

them if they are worn. See Figure 6-5, Conveyor Exploded

Drawing, items 15, 30 and 31 or Figure 6-6, Split Belt

Conveyor, items 19, 23, 31, 35 and 36.

Figure 4-49.

Figure 4-48.

Figure 4-50.

Figure 4-51.

IMPORTANT NOTICES:

• Installation of replacement parts requiring access

to the interior of the oven is permitted only by an

authorized service technician.

• If there are any problems with the operation of the

oven, the authorized service technician must be

called.

• It is suggested to obtain a service contract with a

manufacturer’s authorized service technician.