SECTION 1

DESCRIPTION

3

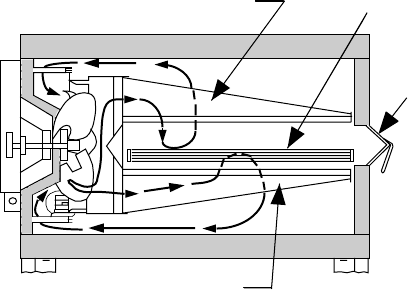

II. PRINCIPLE OF AIR FLOW

The fan-style blower draws air into the oven plenum where

it is heated. The blower then pushes the hot air through the

air fingers into the baking chamber. Each air finger

contains an inner plate and outer plate that form the hot air

into jets, distributing it across a conveyor belt on which the

food product rides. Air is then pulled back into the blower

and the process continues. The curving, black arrows of

Figure 1-4 show this air flow.

A. Heat Transfer and How It Works

1. Heat constantly moves from a warm object to a cold

object. Heat moves using three different paths: Conduc-

tion; Radiation; and Convection.

Conduction:

This path utilizes surface-to-surface con-

tact. The pizza dough in contact with the pan is a good

example of conduction.

Radiation:

This path has to do with objects radiating heat.

Dark objects absorb heat whereas light or shiny objects

reflect more heat. This is the reason that the inside of a

PS536ES-Series Oven is light in color: To reflect more

heat back onto the food product.

Convection:

This path has to do with moving a volume of

air. It explains why hot air rises and cooler air replaces hot

air. An industrial application of this principle is to incorpo-

rate a fan to force the hot air movement, which in turn

increases the heat transfer to the food product.

Each PS536ES-Series Oven has a large fan-style blower

to move the hot air through the air fingers and onto the

product to cook/bake the food product most efficiently.

2. Temperature is the intensity of heat at the point where

it is sensed. As discussed above, heat flows by conduc-

tion, radiation and convection. The speed at which the heat

flows is determined by the temperature difference between

the oven and the food product. The larger the difference,

the faster the heat flows to the item that is being baked.

Upper Air Fingers

Lower Air Fingers

Conveyor Belt(s)

Window

Figure 1-4. PS536ES-Series Oven Air Flow