11

SECTION 2 - AIR FLOW AND HEAT TRANSFER

of making a test to read the bake.

1. Remove all upper air fingers from the oven.

NOTE: As the air fingers are removed, use a felt pen to

mark all parts of the fingers. This includes the mani-

fold, inner plate and outer plate. If a blank or choke

plate is used, mark that plate also. Fingers are marked

in the order shown below, as viewed from the front of

the oven. If there are upper and lower oven cavities,

you should mark the fingers for the upper oven with a

U and those for the lower oven with a L.

VERY IMPORTANT: When the ovens were shipped

from the factory, all of the shutters were pre-ad-

justed for their location within the oven. AII parts

of the fingers must be marked as explained above

and reassembled into their original position.

2. Check the size of the openings at the front of the shut-

ter plates by inserting a drill into the opening. The

factory setting is a #46 drill (0.081/2.06mm).

3. Drill out the four 1/8 pop rivets that are located toward

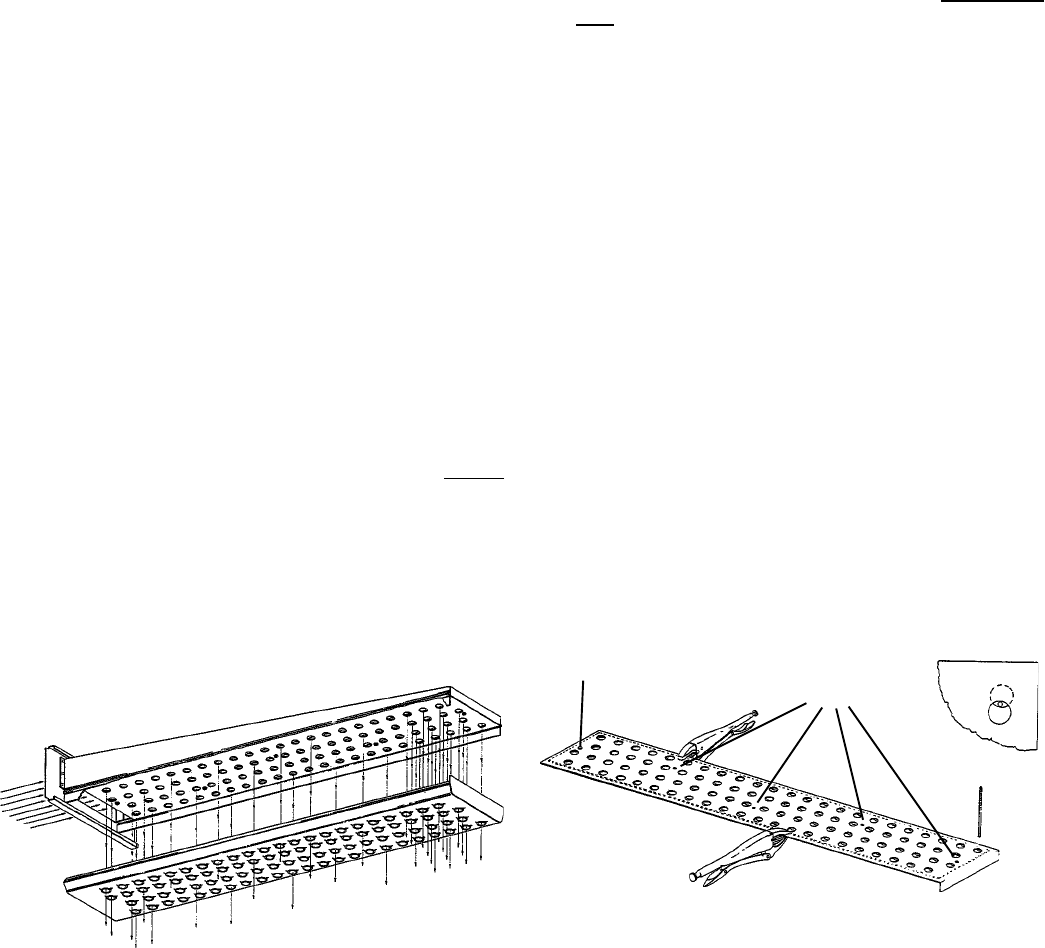

the front of the fingers. See Figure 8.

NOTE: DO NOT drill out the rivet at the back of the air

finger. This is the pivot for the shutter.

4. If the product is lighter at the front of the oven, increase

the opening by 1/16/1.59mm. If the product is darker

at the front of the oven, decrease the opening by 1/16/

1.59mm.

The best way to check the size of the openings is to

use numbered drills as a gauge. An orifice drill set is

ideal for making this adjustment. For example, to in-

crease the opening by 1/16, you would use a #30 drill

(0.1285/3.26mm), which is approximately 1/16 larger

than the original setting measured with the #46 drill

(0.081/2.06mm).

Be sure that the measurement is taken at the largest

point of the opening. See Figure 8.

5. While holding the new adjustment, clamp the two shut-

ter plates together (two pairs of vice grip pliers are ideal)

and drill holes for new pop rivets.

NOTE: Most of the old rivet holes can be reused if the

old hole is simply elongated. However, if the hole is not

properly elongated, the new rivets may pull the plates

out of adjustment when they are installed.

IMPORTANT: Aluminum 1/8 pop rivets are ideal

for use here. They are much easier to drill out

than stainless steel rivets.

6. Repeat these steps to adjust all upper air fingers. Then,

reinstall the fingers into the oven.

7. Perform another test bake.

lMPORTANT: This test bake must be an exact dupli-

cate of the first test bake. If you change any of the

conditions you will change the results.

If the test indicates an even bake, your adjustment

is complete.

If the test indicates that the bake is still uneven,

you will need to repeat the adjustment procedure

until an even bake is obtained. By keeping the

tests identical, you should be able to determine

how much more the shutter plates should be opened

or closed to achieve a balanced bake without re-

moving the fingers for a third time.

VERY IMPORTANT: After attaining a proper adjust-

ment of the fingers, each air finger should be marked

with a metal stamp showing its position inside the oven.

This will eliminate future problems of operators mixing

the adjusted fingers when cleaning the oven.

Figure 8

PS300/350-style air finger with adjustable shutter plate

Higher pressure at the

front of the fingers is

regulated by the

shutter openings

Pivot

DO NOT

drill out

Drill out

rivets

Vise grip

pliers

Insert drill bit

to check size

of opening