MVH-150GH/D — PARTS & OPERATION MANUAL — REV. #2 (12/04/06) — PAGE 19

Engine Oil Replacement:

1. Replace engine oil, first in 20 hours of operation and every

100 hours afterwards.

2. Oil may be drained more easily when it is warm after

operation (For more details, see separate HONDA Owner's

Manual).

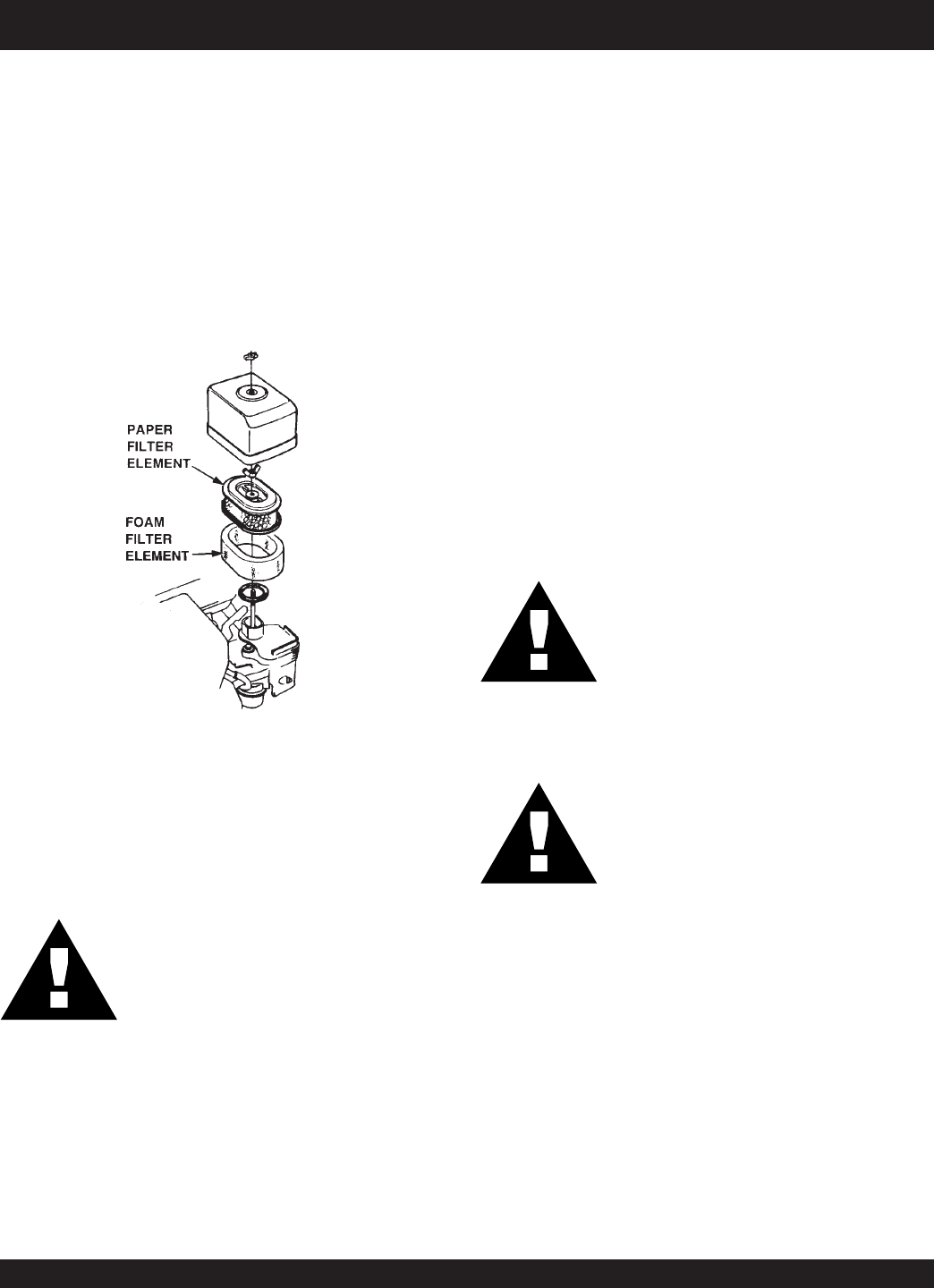

Air Filter

1. The air filter element should be cleaned because a clogged

air cleaner can cause poor engine starting, lack of power

and shorten engine life substantially.

2. To clean or replace air filter loosen the wing nut on the air

filter housing (Figure 16), remove the cover and take out air

filter cartridge. If only cleaning of the air filter is desired blow

through the air filter cartridge from the inside, moving a jet of

dry compressed air up and down until all dust is removed.

z

Reinstalling the V-belt

Engage V-belt to lower vibrator pulley and push the V-belt to left

side of upper clutch and, in the same manner as in removal,

rotate offset wrench clockwise so that the V-belt goes back on.

z

Replacing the V-belt

Remove the upper and lower belt covers. Engage an offset

wrench (13 mm) or the like to vibrator pulley (lower) fastening

bolt. Engage waste cloth or the like at midway of V-belt on the left

side and while pulling it back strongly, rotate the offset wrench

clockwise so that the V-belt will come off.

z

Checking Clutch

Check the clutch simultaneously with V-belt checking. With belt

removed, check outer drum of the clutch for seizure and "V"

groove for wear or damage with your eyes. Clean the "V" groove

as necessary. Wear of lining or shoe should be checked with

running check. If the shoe is worn, power transmission becomes

deficient and slipping will result.

CAUTION:

Whenever the compactor's vibration becomes

weak or lost during normal operation regard-

less of operation hours, check the V-belt and

clutch immediately.

MVH-150GH/D MAINTENANCE

Vibrator Oil Level Check

1. In every 300 hours of operation, with the machine positioned

horizontally, remove vibrator oil level check plug (Figure 5)

off vibrator (14 mm wrench) and see if oil is up to filler port.

Be sure to clean area around check hole to prevent dirt and

dust from entering.

2. In every 300 hours of operation, replace oil (capacity 400

cc). For draining oil through level check hole, have the

machine inclined with a sleeper or the like placed under the

compaction plate on opposite side.

* Use engine oil 10W-30 for this lubrication.

CAUTION:

Always clean the area around the vibrator oil

level check hole before removing oil check

plug. This will prevent dirt and debris from

entering the system.

CAUTION:

NEVER attempt to check the V-belt with the

engine running. Severe injury can occur if your

hand (Figure 7) gets caught between the V-belt

and the clutch. Always use safety gloves.

Checking and Replacing the V-Belt and Clutch

1. After 200 hours of operation, remove the upper belt cover to

check the V-belt tension. Tension is proper if the belt bends

about 10 mm when depressed strongly with finger between

shafts. Loose or worn V-belts reduces power transmission

efficiency, causing weak compaction and reduces the life of

the belt itself.

Figure 16. Air Filter