MQ-MIKASA MVH-402DSB PLATE COMPACTOR — PARTS & OPERATION MANUAL — REV. #2 (03/30/05) — PAGE 19

MVH-402DSB—OPERATION

4. To make the compactor move in the reverse direction pull the

travel lever ( Figure 13) backwards.

5. Firmly gasp the compactor's hand grip, the compactor will

begin moving in the desired position when the direction lever

has been placed in the desired position.

6. Slowly walk behind the compactor and be on the lookout for

any large objects or foreign matter that might cause damage

to the compactor or bodily injury.

7. If travel lever is placed in the neutral position, the machine will

vibrate in place.

8. To move the compactor laterally, hold the hand grip firmly and

swing compactor. Do not swing compactor while gripping the

travel lever.

STOPPING

1. Return the throttle lever to the START position

(Figure 9). Allow the machine to cool down for 2 to 3

minutes.

2. Turn the throttle lever to the STOP position (Figure

15) to stop the engine. In a motor start, return the key

switch to the STOP position (Figure 16) as soon as

the engine stops.

3. Close the fuel cock (Figure 8).

Figure 15. Throttle Lever (Stop)

Figure 16. Starter Switch (STOP)

Emergency Shutdown

1. Move the throttle lever quickly to the

STOP

position,

and place the engine

IGNITION

switch in the

OFF

position.

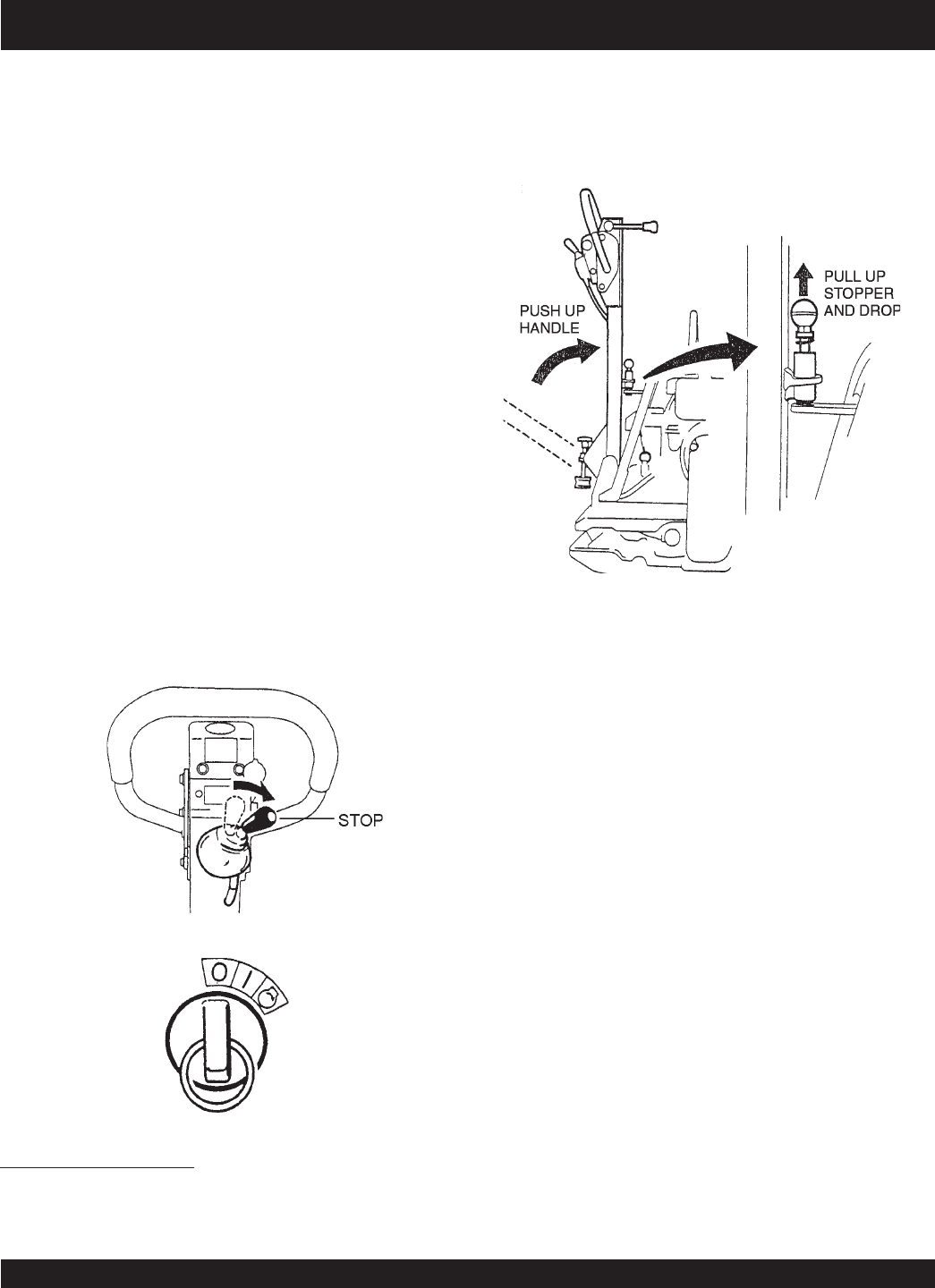

STOWING THE HANDLE

1. Push up the handle (Figure 17).

2. Pull the stopper grip upward into the hole of the guard

frame to lock the handle.

Figure 17. Stowing the Handle

LIFTING

1. Use a crane or lift to load and unload the machine. A

skilled crane operator is required to perform the job.

2. When lifting the machine, check for any damaged or

loose bolts, lifting hooks, and shock mounts.

3. Check any damaged or loose bolts in the guard frame to

avoid machine sliding off.

4. Make sure that the machine is shut off before machine is

lifted.

5. Use reliable cable for lifting.

6. Always lift the machine vertically and keep the

machine away from workers and animals.

7. Do not lift the machine higher than the required

height.

TRANSPORTING

1. Always make sure that the machine is shut off while

being transported.

2. Check that the fuel cap is properly closed and

tightened.

3. When traveling long distances or on rugged terrain,

drain the fuel of the machine before transporting.

4. Tie down the machine securely on the

transportation so that it will not move or topple over.