2

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

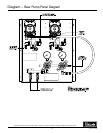

Installation – Beer Pump Panels

■ Use panel as a template to mark where holes

should be drilled on cooler wall. Beer pump

panels should not be installed with a height

of greater than 5 feet from the cooler floor. A

height greater than 5 feet will potentially cause

flow issues and require system re-balancing.

(Note: Make sure panel is level and pumps are

in the vertical position).

■ Drill

9

/64” pilot holes in cooler wall. Use fasteners

provided in installation kit to mount the beer

pump panel to the cooler wall.

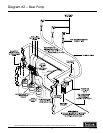

■ Push CO2 supply line over barbed CO2 supply

inlet.

(See diagram on page 3). Position clamp

over joint and tighten. Always use

3

/8” I.D.

braided tubing for gas supply line. Gas supply line

should have drops going to each panel. (Never

connect supply line in a series hook-up

.

Push beer line (from trunk housing) over barbed

liquid outlet on flow reversal valve. (See

diagram on page 3). Position clamp over

joint and tighten.

■ Push connector hose over liquid inlet on beer

pump flow reversal valve inlet fitting.

(See

diagram on page 3). Position clamp over joint

and tighten. (NOTE: Connector hose should not

exceed 10 feet in length)

.

Install washer into hex nut on opposite end of

connector hose. Connect to top threaded fitting

of Perlick Smart Coupler.

■ Cut a piece of CO2 tubing (red

9

/16” vinyl tubing)

and push one end onto barbed CO2 outlet to

Keg Couplers (See diagram on page3). Position

clamp over joint and tighten. Push the other end

over the barbed gas inlet on the Perlick Smart

Coupler. Position clamp over joint and tighten.

Important Notes

◆ CAUTION: If using CO2 as a pressure supply for

pumps, pump exhaust must be vented to a well

ventilated area to avoid possible asphyxiation.

◆ Never use a single keg to supply more than one

beer pump. Using a single keg to supply more

than one pump will create flow problems, pump

burn out or premature Smart Coupler shut-off.

◆ Pump panels should never be installed more

than 5 (five) feet above the cooler floor. A height

in excess of 5 (five) feet causes additional

pressure drop between the keg and pump inlet

which may cause degassing or premature Smart

Coupler shut-off.

◆ Beer pumps must be used in combination with

an empty keg sensing device. If an empty keg

sensing device is not used premature pump

failure will occur.

◆ If using compressed air as pressure source to

drive pumps, pump and keg regulators need to

be seperated. Air must be clean and dry.

Form No. Z2149A

Rev. 10.11.06