4

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

How to Operate – Beer Pump Panels

■ Adjust primary CO2 regulator by turning

adjusting screw counterclockwise until it turns

freely, then turn hand valve counterclockwise

on CO2 cylinder to the fully open position. Next,

turn regulator adjusting screw clockwise until

required system pressure plus an additional 15

psig is reached.

Note: If CO2 is only being used for keg-

applied pressure, adjust to approximately

40 psig.

Note: If using air to drive beer pumps,

adjust the air compressor output regulator

pressure to a minimum of 15 psig. greater

than the maximum required system

pressure required to operate the beer

pumps. Maximum setting 100 psig.

■ Adjust secondary CO2 regulator which

supplies the keg pressure located on the

beer pump panel to the proper pressure

setting. Setting depends on beer brand and

temperature. Desired goal is to maintain the

natural carbonation in the beer. Open the shut-

off valves.

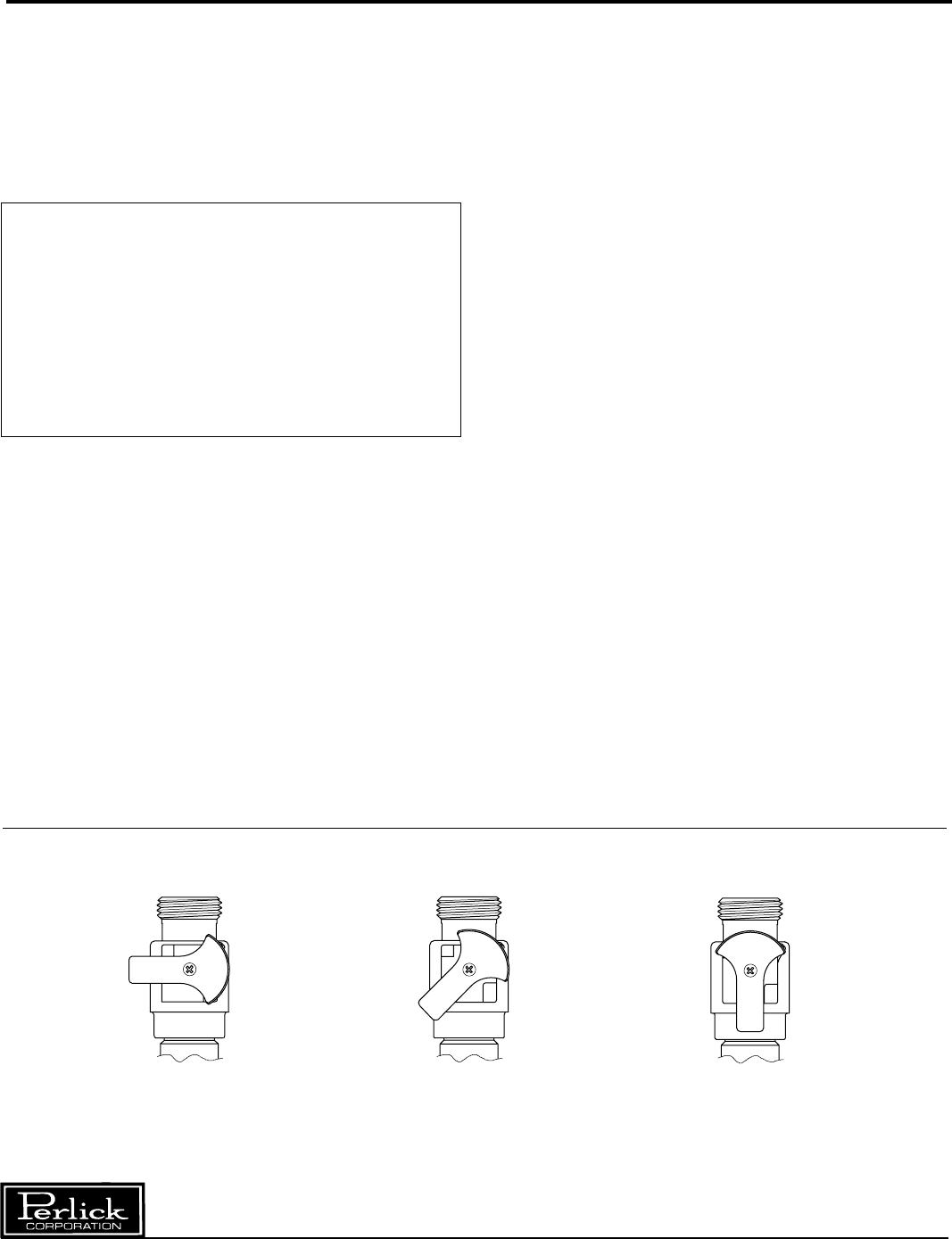

■ Ensure the Probe Valve on the Perlick Smart

Coupler is in closed position. See figure 1.

Ensure the Beer Pump Flow Reversal/Dispense

handle is in the dispense position. Adjust the

Secondary Air/ CO2 regulator located on the

beer pump panel to a minimum operating

pressure of 10 psig.

■ Connect the coupler to a regulated water supply

with pressure less than 30 psig. Note: Pump

damage may occur with pressure higher

than 30 psig.

■ Open the water supply. Then open probe valve

on Perlick Smart coupler to the 45° position.

See figure 2. The beer pump will slowly pump

up the beer line in the trunk housing to set psig.

Note: If pump continues to run for longer than

expected, check lines for possible leaks at one

or more of the connections.

■ Gradually increase secondary regulator

pressure to the designed system pressure to

achieve a flow rate of one gallon per minute

from the dispensing head. Note: Maximum

beer pump operating pressure is 90 psig.

■ Open dispensing head faucet to purge air

trapped within the tubing.

■ Check all gas and liquid line fittings and

connections for leaks.

■ Close probe valve on Perlick Smart Coupler.

(See figure 1) and disconnect coupler from

regulated water source.

■ Clean beer system. After cleaning and rinsing

the system, make sure the beer line is full of

cold water (beer dispensing from warm beer

lines will be poor quality).

■ Tap fresh keg with Perlick Smart Coupler. Open

dispensing head faucet until clear beer flows.

Figure 1

Closed Position

Figure 2

45° or Cleaning Position

Figure 3

Open Position

Smart Coupler Probe Valve Lever Positions

Form No. Z2149A

Rev. 10.11.06