OPERATION GFS SERIES TUBE FRYERS

PAGE 12 OPERATOR’S MANUAL 1182026 REV 2

OPERATION

OPERATION

NOTICE

These procedures must be followed by qualified personnel or warranty will be voided.

All Southbend GFS Series Tube Fryers are immersion tube fryers. This is the most efficient method of

transmitting heat into the oil. The tubes are actually large heat exchangers. Each tube is heated by a burner

at its front that propels its flame and heat into the tube, toward the rear, where it is vented into a flue box.

The combined heat transfer area of the tubes is much greater than the other types using element coils or

under-fired pots. Consequently, heat transfer per square inch is lower, as is the temperature, but because of

the increased surface area, immersion tube fryers transfer more heat into the oil. The lower temperature of

the heating surface prevents scorching and carbonization of the oil. Higher heat transfer rate gives faster

recovery between loads.

Another advantage of immersion tube fryers is the cold zone. As oil is heated it passes between and over the

tubes and rises into the frying zone, where it imparts heat into the product. After giving up heat, it descends

to the cooler zone below the tubes. Food particles and crumbs are dropped and trapped in the cold zone as

the oil awaits to be recirculated. The cold zone concept helps keep the oil circulating and clean of debris.

! WARNING

BURN HAZARD

Contact with hot oil will cause severe burns. Always use caution. Oil at 200°F is more dangerous than

boiling water.

! CAUTION

NEVER OPERATE THE FRYER WITHOUT SUFFICIENT OIL TO COVER THE TUBES.

Lighting

! CAUTION

IF YOU SMELL GAS DURING THE LIGHTING PROCEDURE, IMMEDIATELY SHUT OFF THE GAS

SUPPLY UNTIL THE LEAK HAS BEEN CORRECTED.

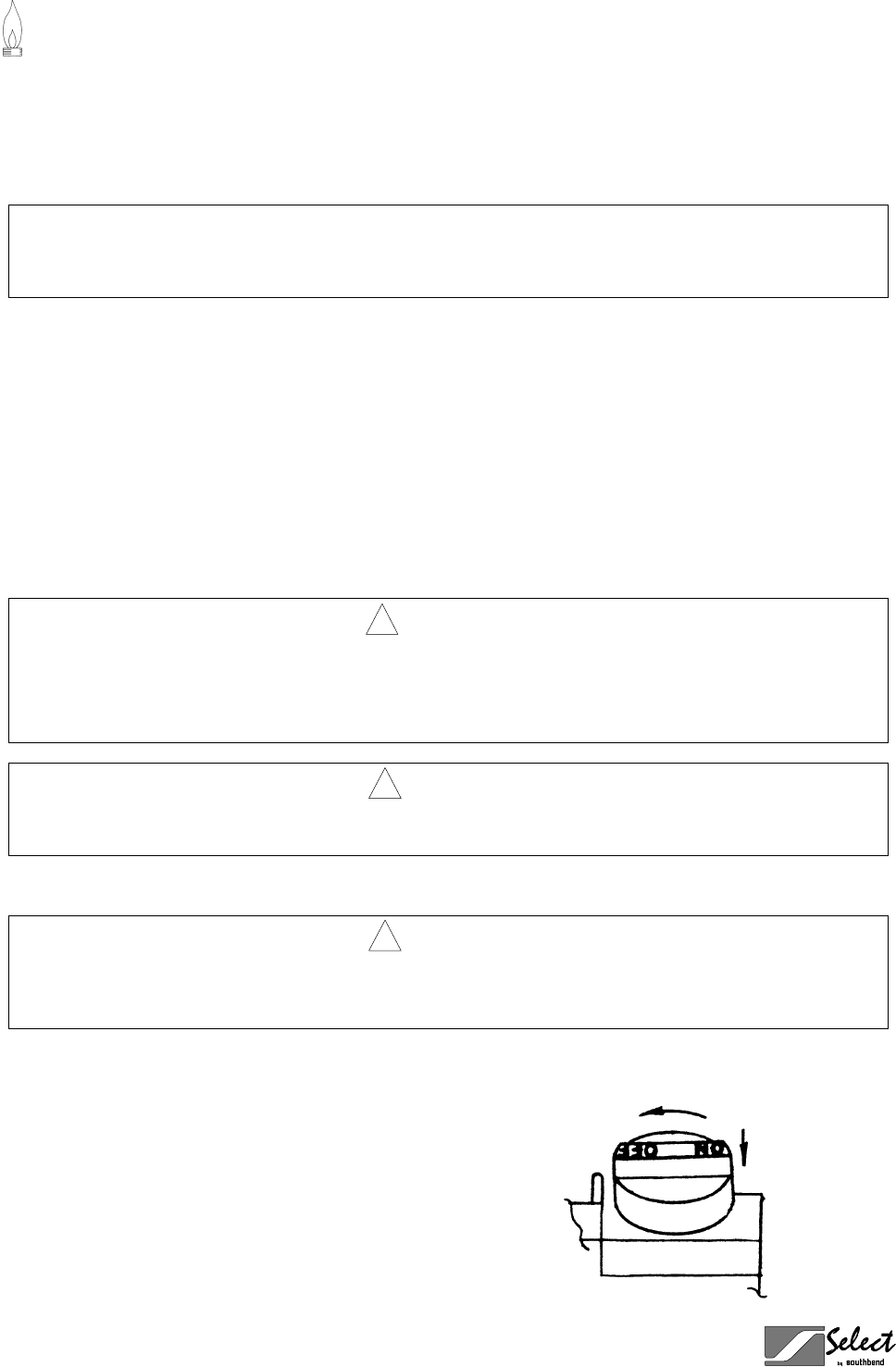

Open the burner compartment door and do the following:

1. Turn thermostat to “OFF” (lowest position).

2. Press down the knob of the combination gas

valve, turn it counterclockwise to the “PILOT”

position, and continue to press the knob down.