BJ5-615 Chapter 5: Maintenance 36 of 85

5. Attach the bearing housing to the bearing seats using screws.

6. Push the distance sleeve onto the rotor axis.

7. Put the gear onto the rotor axis

8. Put back the rotor cover plates

9. Put in the screen

10. Pull on V-belts and adjust the V-belt tension force.

11. Attach the V-belt cover.

12. Carry out a test run.

NOTE:

• The roller bodies will be damaged unless the mounting forces engaged into inner

ring.

• The hardened bearing rings are sensitive to impact stress; never hit the rings with

the hammer. Use a brass arbor or a striking bushing (piping piece) made from a

soft material. The inner diameter of the striking bushing should be only slightly

larger than the diameter of the bearing base.

• The bearing is then pushed onto the shaft using light blows. The force of pressure

must be evenly distributed on the circumference of the bearing ring.

Lubricating the Main Bearings

An important requirement for high operational safety and long service life of the arrangement

of bearings is the correct lubricant supply. Every machine is greased and checked in test runs

before delivery.

NOTE: Unsuitable lubricant, lubricant deficiency, excessive lubricant, or impurities in the

lubricant lead to overheating and extreme wear of the bearings.

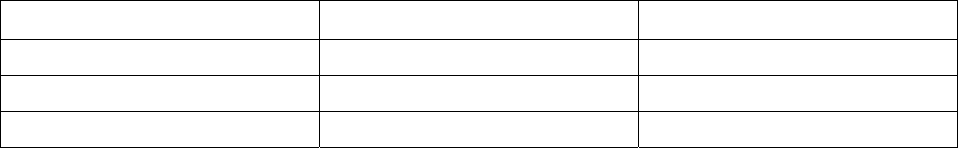

Lubrication Intervals

Shift Operation Replace Lubricant Check

One shift operation Every 18 months Monthly

Two shift operation Every 9 months Monthly

Three shift operation Every 6 months Monthly

Check lubricant quality

You can judge whether the lubricant needs to be replaced by checking for the

following features:

• Change in consistency

• Discoloration

• Degree of soiling