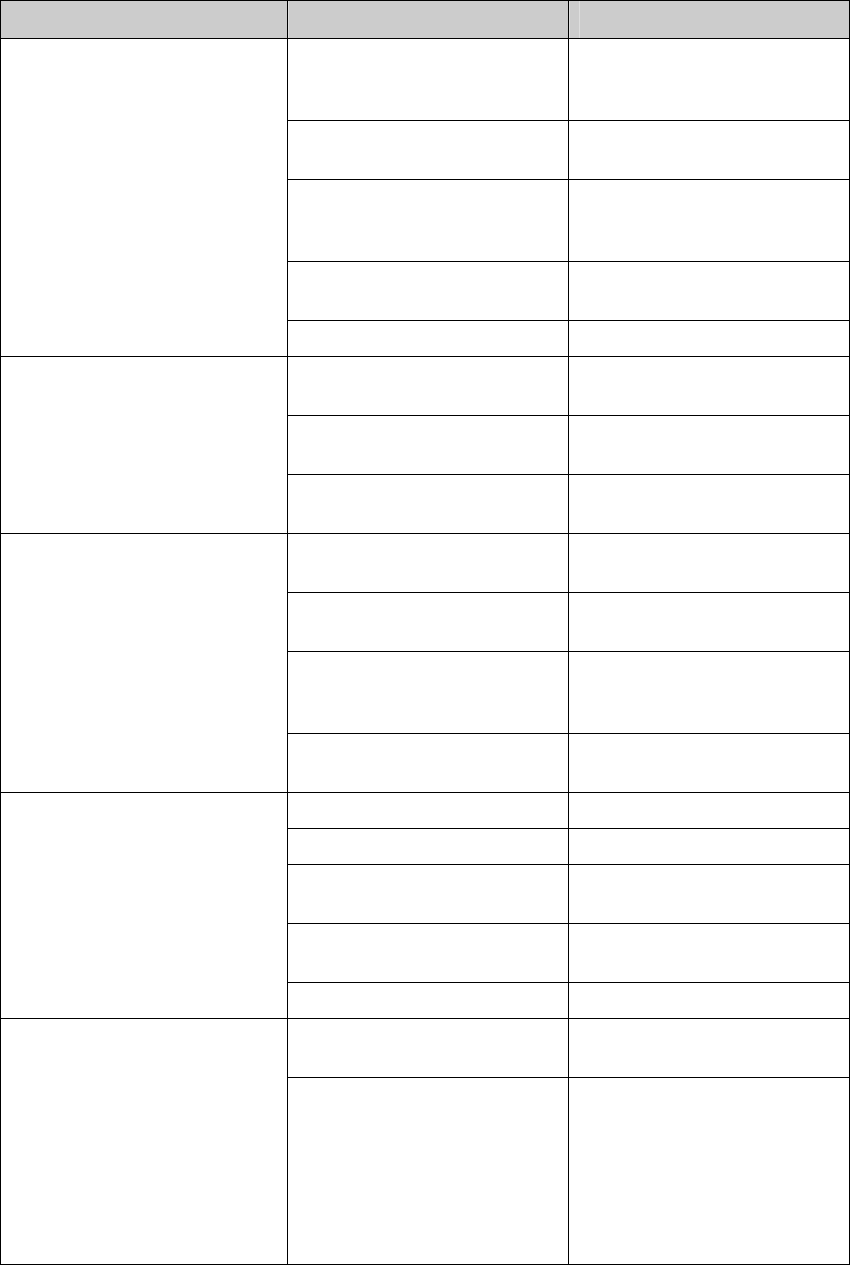

BJ5-615 Chapter 6: Troubleshooting 55 of 85

Problem Possible Cause Possible Remedy

View first 5 possible causes

for “Machine blocks or

switches itself off”

View first 5 possible

remedies of “Machine blocks

or switches itself off”

Screen perforation too small.

Insert a screen with larger

perforation.

Cutters wrongly sharpened.

Modify cutter finish only

after consulting the

service department.

Material rubs against the

housing wall.

Fit anti-winding device.

Overheating of the shredded

material.

Insufficient cooling. Fit rotor cooling.

Rotor out of balance.

Weight cutters, balance

rotor.

Bearing damage.

Check bearings and replace

if necessary.

Unusual vibrations.

Anti-vibration pads defective.

Check mounting pads and

replace if necessary.

Bearing damage.

Check bearings and replace

if necessary.

Cutter finish.

Check cutter and sharpen or

replace if necessary.

Wrong cutting gap.

Check cutting gap and set

following the instructions in

this manual.

Extreme cutter wear.

Foreign matter.

Fit feed device with metal

detector.

Too much grease in bearing. Reduce amount of grease.

V-belts too tight. Reduce tension.

Rubbing on housing sealing

ring.

Check sealing ring and oil or

replace.

Bearing damage.

Check bearings and replace

if necessary.

Bearings too hot.

No grease in bearing. Lubricate bearing.

Screen worn.

Renew screen (possibly

using manganese steel).

Too many fines in shredded

material.

Unsuitable screen

perforation.

Replace screen after

consulting the service

department.