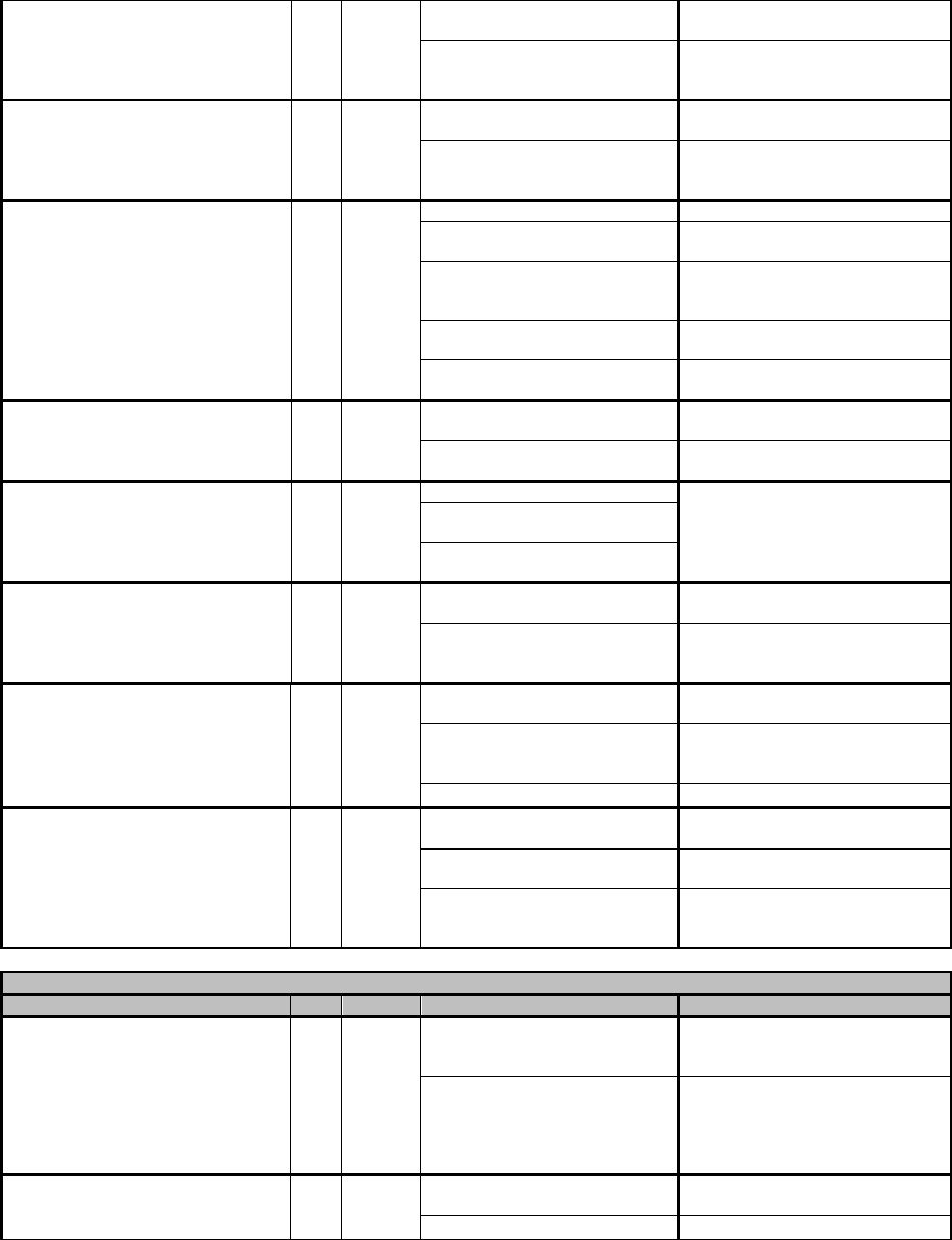

GP Series Portable Chillers Chapter 6: Troubleshooting 52 of 90

Water cooled condenser valve

stuck open

Verify cooling valve operation.

Fan VFD output at 100%

Verify VFD is in remote versus

manual operation. Verify

controller output to VFD.

Low Fluid Temp Fault 9 CC

Low process fluid flow

Verify system valve operation

and adjust if necessary

Plugged Y-strainer

Clean y-strainer through blow-

down valve or cleaning internal

strainer.

Low Suction Pressure Fault 10 CC

System low on refrigerant

Contact Customer Service

Liquid line valves closed

Verify wiring or output between

controller and valve

Chilled fluid setpoint too

close to freeze protection

setpoint.

Adjust setpoint or fluid

freezepoint temperature (will

require adding glycol to fluid)

Process fluid flow rate too

low.

Verify system valve operation

and adjust if necessary

Thermal expansion valve

failure.

Contact Customer Service

Low Superheat Fault (only will

appear if optional sensor pack is

installed)

11 CC

Thermal expansion valve

failure

Contact Customer

Temperature Sensor Failure

Verify sensor wiring between

controller and sensor.

Suction Pressure Sensor Failure 12 CC

Sensor failure

Check the wiring connection at

the sensor, and at the controller.

If necessary replace sensor.

Electrical connection at

sensor open

Electrical connection at

controller open

Leaving Water Temp Sensor

Failure

13 SC

Sensor wires loose from

controller terminal block

Check the wiring connection at

the controller terminal block

Sensor wires broke between

sensor and controller terminal

block.

Replace Sensor

Low Level Fault 14 SC

Tank level too low

Verify tank level parameters.

Add fluid if necessary.

Optional water makeup valve

failure

Verify wiring between

controller and makeup valve.

Replace valve if necessary

Tank level sensor failure

Replace Sensor

No Flow 15 SC

System valve(s) closed

Verify that all system valves are

operational and adjust.

Low flow sensor failure

Verify the sensor at the sensor

and at the terminal block.

Pump failure

Verify the operation of the

pump (i.e. motor circuit

protector or pump rotation)

CC = Compressor Critical SC = System Critical PC = Process Critical W = Warning

Alarm Name

#

Type

Possible Cause

Solution

Pump Overload 16 SC

Motor circuit protector open

Verify motor circuit protector

operation. Verify motor wiring

and amp draw while under load.

Pump flow rate in excess of

capacity

Verify system valves are

operational and properly set.

Contact customer service or

sales if pump is sized too small

for application.

High Fluid Temp Fault 17 SC/W

Fluid temperature higher than

parameter.

Verify parameter and adjust if

necessary.

Refrigeration system fault

Check for any refrigeration