11

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

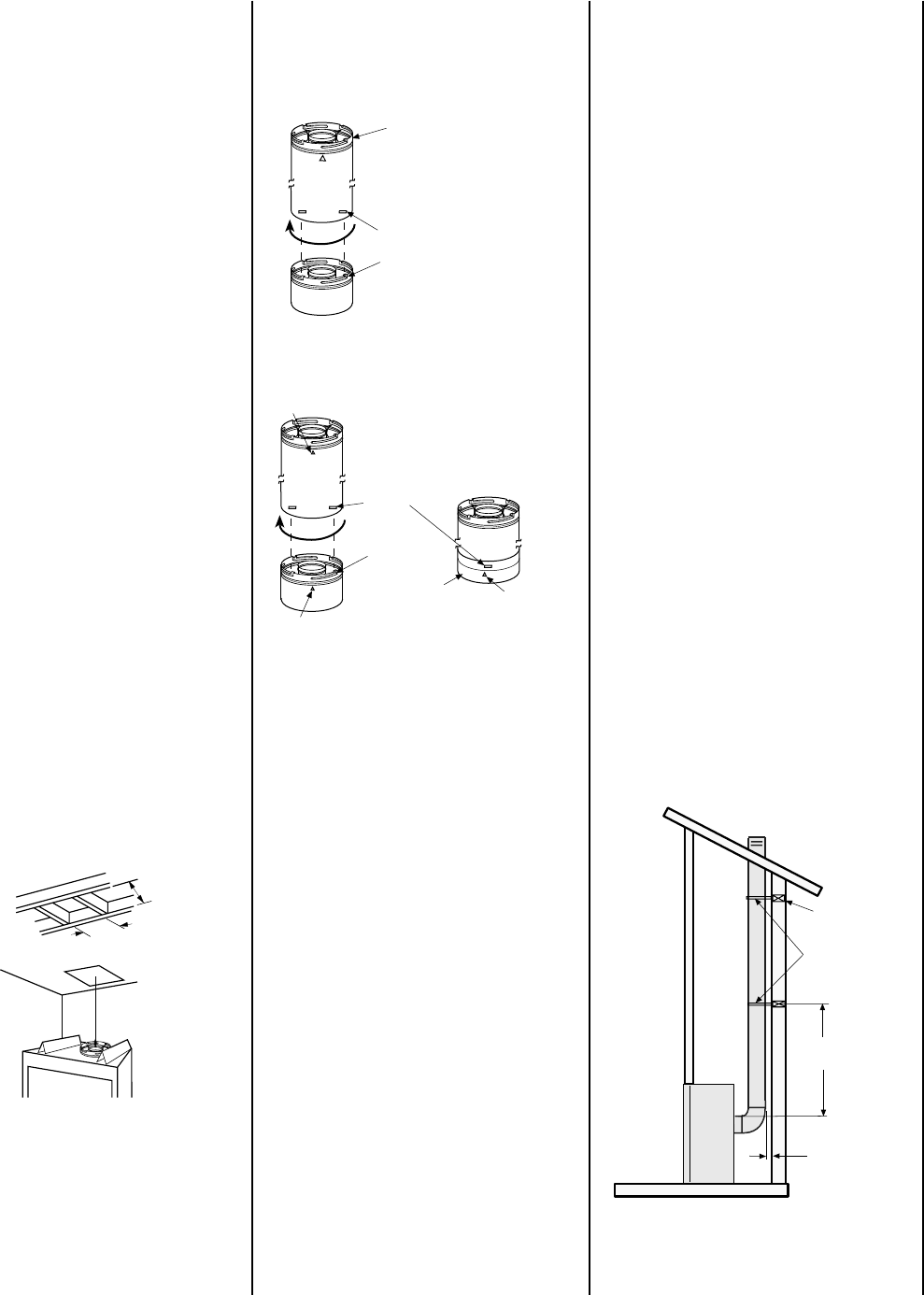

Figure 21

To add another vent component to a length of

vent run, align the dimpled end over the inclined

channel end of the previously installed section,

adjusting the radial alignment until the four

locking dimples are aligned with the inlets of the

four incline channels of the previous section.

Push the vent component against the previous

section until it fully engages, then twist the

component clockwise running the dimples

down and along the incline channels until they

seat at the end of the channels. This seating

position is indicated by the alignment of the

arrow and dimple as shown in

Figure 20.

D. Install firestop/spacer at ceiling - When using

Secure Vent, use SV4.5BF firestop/spacer at ceil-

ing joists; when using Secure Flex, use SF4.5BF

firestop/spacer. If there is living space above the

ceiling level, the firestop/spacer must be installed

on the bottom side of the ceiling. If attic space is

above the ceiling, the firestop/spacer must be

installed on the top side of the joist. Route the vent

sections through the framed opening and secure

the firestop/spacer with 8d nails or other appro-

priate fasteners at each corner.

Remember to maintain 1" (25 mm) clear-

ance to combustibles, framing members,

and attic or ceiling insulation when running

vertical chimney sections.

E. Support the vertical vent run sections -

Support the vertical portion of the venting sys-

tem every 8 feet (2.4m) above the fireplace vent

outlet using field provided support straps (con-

ventional plumber's tape).

Secure the plumber's

tape to the framing members with nails or

screws.

1 inch

(25.4 mm)

minimum

clearance to

combustibles

Support Straps

(Plumber’s tape)

8 feet (2.4 m)

Maximum

Blocking

Figure 18

Figure 20

Figure 19

Vertical (Offset) Installation

Analyze the vent routing and determine the

quantities of vent sections and number of el-

bows required. Refer to Vertical Vent Figures

and Tables on page 13 and 14 to select the type

of vertical installation desired. Vent sections

are available in net lengths of 4 ¹⁄₂" (114 mm),

10 ¹⁄₂" (267 mm), 22 ¹⁄₂" (572 mm), 34 ¹⁄₂" (876

mm) and 46 ¹⁄₂" (1181 mm). Refer to the Vent

Section Length Chart on page 10 for an aid in

selecting length combinations. Elbows are avail-

able in 90° and 45° configurations. Refer to

Figure 22

for the SV4.5E45 and SV4.5E90

elbow dimensional specifications.

Where required, a telescopic vent section

(SV4.5LA) may be used to provide the installer

with an option in installing in tight and confined

spaces or where the vent run made up of fixed

length pieces develops a joint in a undesirable

location, or will not build up to the required

length. The SV4.5LA Telescopic Vent Section

has an effective length of from 1 ¹⁄₂" (38 mm) to

7 ¹⁄₂" (191 mm). The SV4.5LA is fitted with a

locking inclined channel end (identical to a

normal vent section component) and a plain

end with 3 pilot holes. Slip the plain end over the

locking channel end of a standard SV4.5 vent

component the required distance and secure

with three screws.

Maintain a minimum 1" (25 mm) clearance to

combustible materials for all vertical elements.

Clearances for all horizontal elements are 3"

(76 mm) on top, 1" (25 mm) on sides and 1"

(25 mm) on the bottom.

A. Frame ceiling opening - Use a plumb line from

the ceiling above the appliance to locate center of

the vertical run. Cut and/or frame an opening,

10¹⁄₂" x 10¹⁄₂" (267mm x 267mm) inside dimen-

sions, about this center mark (

Figure 18

).

To attach a vent component to the appliance

collar, align the dimpled end over the collar,

adjusting the radial alignment until the four

locking dimples are aligned with the inlet of the

four inclined channels on the collar (

refer to

Figure 19

). Push the vent component against

the collar until it fully engages, then twist the

component clockwise, running the dimples

down and along the incline channels until they

seat at the end of the channels.

The unitized design of the Secure Vent com-

ponents will engage and seal both the inner

and outer pipe without the need for sealant or

screws. If desired, a #6 x ¹⁄₂" screw may be

used at the joint, but is not required as the pipe

will securely lock when twisted.

Note: An elbow may also be attached to the

appliance collar. Attach in the same manner as

you would a vent section.

C. Attach vent components to each other -

Other vent sections may be added to the pre-

viously installed section in accordance with

the requirements of the vertical vent figures

and tables.

B. Attach vent components to appliance -

Secure Vent SV4.5 direct vent system compo-

nents are unitized concentric pipe components

featuring positive twist lock connections (

see

Figure 19

).

10¹⁄₂” Min.

(267 mm)

10¹⁄₂” Min.

(267 mm)

First Vent

Component

Align the dimple (four places)

with the opening of the locking

incline channel on appliance

collar. Twist vent component

clockwise to engage and seal.

Locking

Incline Channel

Dimple

Appliance collar

Vent / Appliance Collar

Connection

Align the dimple (four places) of the

upper vent section with the opening of

the locking incline channel on the

lower vent section. Twist vent

component clockwise to engage and

seal until arrow and dimple align.

Locking

Incline Channel

Dimple

Arrow

Connected

Vent Sections

Vent / Vent Section

Connection

Arrow

Arrow

All of the appliances covered in this document are

fitted with collars having locking inclined chan-

nels. The dimpled end of the vent components fit

over the appliance collar to create the positive

twist lock connection.