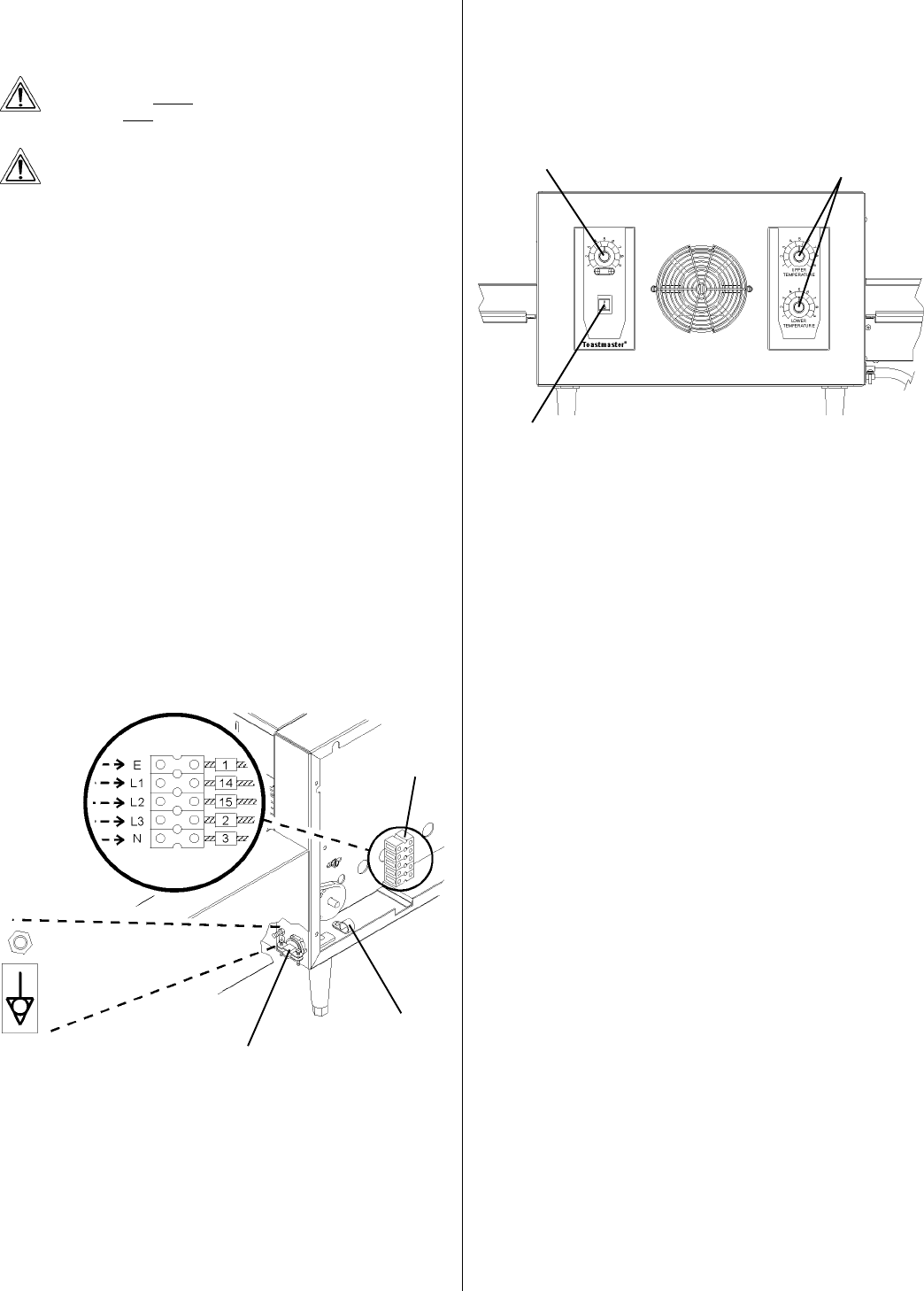

3

Equipotential ground lug

and symbol (all ovens)

Cable clamp

Terminal

block

Connector

(3-phase ovens only)

Wiring connections

(3-phase ovens

only)

1. Before proceeding with the electrical connection, check that the

electrical supply matches the ovens requirements. Refer to the

serial plate (Figure 4) and to the electrical specifications shown

on the wiring diagrams at the back of this Manual.

WARNING

ENSURE THAT BOTH THE CIRCUIT BREAKER/FUSED DIS-

CONNECT AND THE POWER ON/OFF (I/O) SWITCH ARE IN

THE O (OFF) POSITION BEFORE PROCEEDING.

WARNING

ENSURE THAT ANY PACKING MATERIAL RESIDUE HAS

BEEN REMOVED FROM INSIDE THE OVENS COOKING

CHAMBER.

2. Single-phase ovens only:

Check that the appropriate receptacle is available for the

power cord plug.

Insert the power cord plug into its receptacle.

3. Three-phase ovens only:

Remove the two screws that hold the rear cover panel in

place; then, remove the cover panel.

Insert the end of the electrical supply through the connector

shown in Figure 5.

Attach the electrical supply wires to their terminal block

connections, as shown in Figure 5.

Secure the supply wires to the floor of the electrical

compartment using the supplied cable clamp. The wires must

not interfere with the drive chain and sprocket. See Figure 5.

Secure the supply as it passes through the connector on the

outside wall of the oven.

Replace the rear wall of the oven and fasten it in place.

4. All ovens:

Connect an equipotential ground wire to the lug shown in Figure

5. The equipotential ground connection must meet current IEC/

CEE and local code requirements.

Figure 5

III. OPERATION

A. Location and Function of Controls

This section provides a basic description of the oven controls, their

location, and the functions they perform. The operator MUST be familiar

with the controls. Refer to Figure 6.

1. Power On/Off (I/O) switch

Switches the oven ON and OFF.

2. Conveyor speed control knob

Adjusts the speed of the conveyor. This controls the bake time.

1 is the minimum speed setting, which produces the longest

available bake time.

9 is the maximum speed setting, which produces the shortest

available bake time.

3-4. Upper and Lower temperature adjustment knobs

Adjust the temperature settings of the upper and lower heating

zones.

1 is the minimum temperature setting, which sets the heating

zone to the lowest available temperature.

9 is the maximum temperature setting, which sets the

heating zone to the highest available temperature.

B. Operation Procedure

1. Adjust the position of the draft curtains at the ends of the cooking

chamber (if necessary). This procedure is described in detail in

Part D, Draft Curtain Adjustment, in this section.

IMPORTANT

When cooking at very high temperatures (a setting of 8 or higher

on either temperature adjustment knob), the oven should be pre-

heated for at least 10 minutes WITH THE DRAFT CURTAINS IN

THE FULLY-LOWERED POSITION. After pre-heating, the curtains

may be repositioned as required.

2. Restore electrical power to the oven at the circuit breaker/fused

disconnect.

3. Switch the Power On/Off (I/O) Switch to the ON (I) position.

4. Adjust the bake time (if necessary) by turning the conveyor speed

control knob. Adjust the upper and lower temperature settings (if

necessary) by turning the temperature adjustment knobs.

5. Allow the oven to pre-heat for at least 10 minutes.

6. Load the entrance end of the conveyor with the food product. The

motion of the conveyor will move the food product into the cooking

chamber.

C. Shutdown Procedure

1. Switch the Power On/Off (I/O) switch to the OFF (O) position.

2. Wait for the ovens cooling fan to turn off.

3. Disconnect electrical power to the oven at the circuit breaker/fused

disconnect.

Figure 6

2. Conveyor

speed control

knob

1. Power On/Off

(I/O) switch

3. Upper and Lower

temperature adjustment

knobs