16

1

2

NATURAL GAS

REGULATION

LP/PROPANE

REGULATION

A

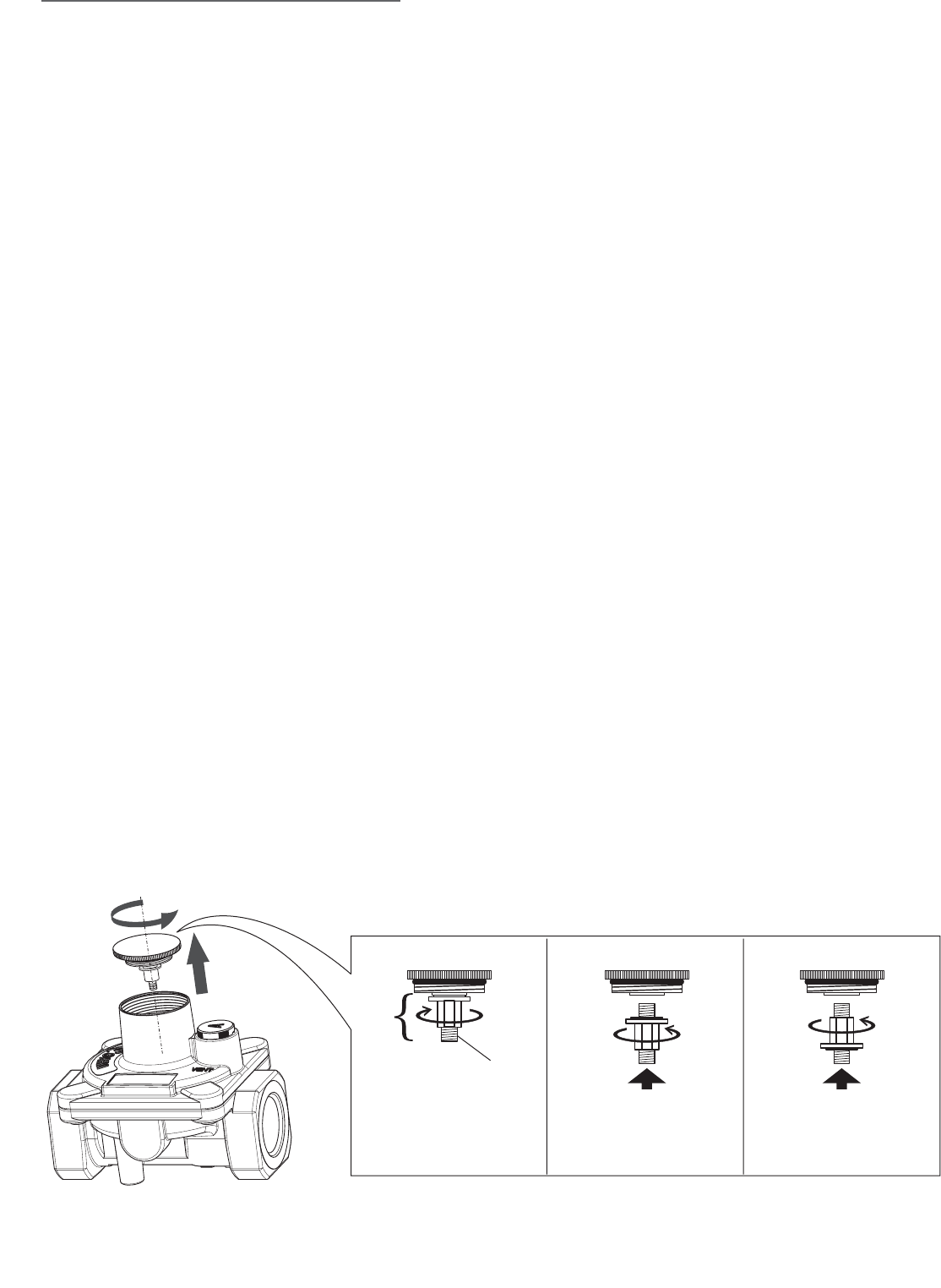

SETTING THE PRESSURE REGULATOR (fig. 5.5)

1. Unscrew the regulator cover;

2. Unscrew the A component, reverse and screw it according to the LP/PROPANE

regulation.

CONVERSION TO LP/PROPANE GAS

Every cooktop is provided with a set of injectors for the various types of gas.

Select the injectors to be replaced according to the table below.

The nozzle diameters, expressed in hundredths of a millimetre, are marked on the

body of each injector.

ቦ

Fig. 5.5

4. Rigid Pipe Connections:

If rigid pipe is used as a gas supply line, a combination of pipe fittings must be used

to obtain an in-line connection to the cooktop. All strains must be removed from the

supply and fuel lines so cooktop will be level and in line.

• Use joint compounds and gaskets that are resistant to action of natural or propane

gas on all male pipe threads.

• Do not over tighten gas fitting when attaching to pressure regulator. Over

tightening may crack regulator.

5. Leak Testing:

IMPORTANT: Leak testing of the appliance shall be conducted as follows:

• After final gas connection is made, turn on manual gas valve and test all

connections in gas supply piping and appliance for gas leaks with a soapy water

solution. During this test all appliance gas valves have to be closed.

• In order to avoid property damage or serious personal injury, never use a Iighted

match. If a leak is present, tighten joint or unscrew, apply more joint compound,

tighten again and retest connection for leak.