6. Replace thermostat knob.

A. Turn knob to 350°F and verify increase in

flame height on burner ports.

7. Turn knob back to lowest setting. Verify decrease

in by-pass flame height on burner ports and that

burner remains lit.

STANDARD OVEN THERMOSTAT

TEMPERATURE ADJUSTMENT

NOTE: Calibration on this "modulating thermostat"

version is made using the knob for temperature

adjustments and not the inner screw as on previous

versions.

1. Place a thermocouple type temperature probe

(type K preferred) in center of oven to verify

actual temperatures throughout adjustment.

2. Turn thermostat knob to 350°F. Wait 15 minutes

for oven to heat up.

3. Turn knob to the lowest setting and check the by-

pass flame for proper adjustment as outlined

under STANDARD OVEN THERMOSTAT BY-

PASS FLAME ADJUSTMENT.

4. Turn knob back to 350°F and wait for

temperature to stabilize (approximately 30

minutes). When the temperature stabilizes take

a temperature reading. If actual temperature is

more than 15°F from knob setting, calibrate as

follows:

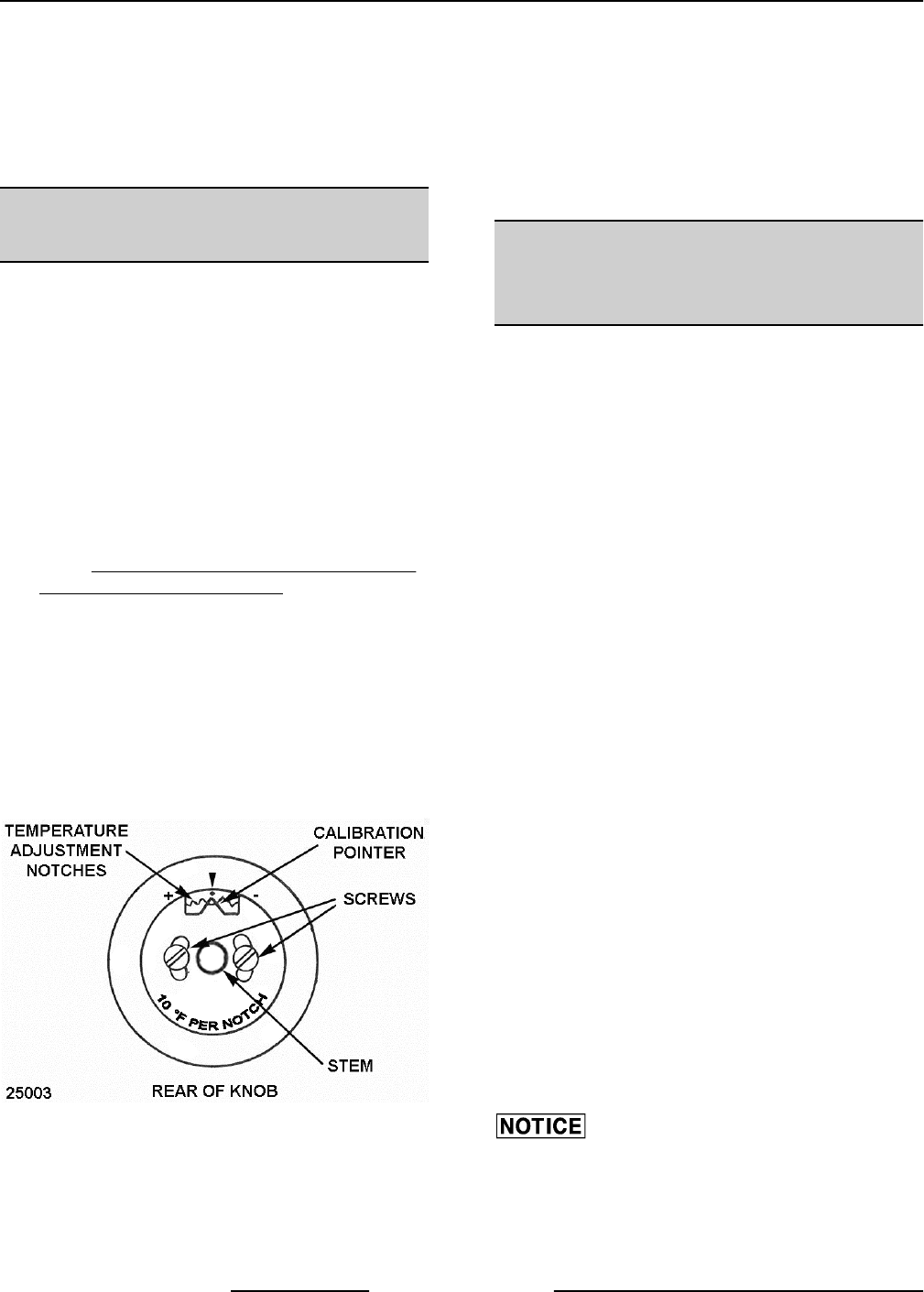

5. Pull off thermostat knob.

6. Loosen two screws on the back of knob.

Fig. 71

7. Grasp stem and push it out from knob to clear the

temperature adjustment notches. Move

calibration pointer at base of stem clockwise to

lower temperature or counterclockwise to raise

temperature as close to the desired setpoint as

possible. Each notch equals 10°F.

8. Tighten screws and replace knob.

9. Verify temperature setting at 400°F and 450°F.

Wait 15 minutes for oven to heat up at each

setting. If actual oven temperature is not within

15°F, readjust as outlined in this procedure. If

three consecutive adjustments do not produce

acceptable results, replace thermostat and verify

calibration.

CONVECTION OVEN

THERMOSTAT-COMBO VALVE

ADJUSTMENT

Operation

The "snap action" thermostat-combo valve is self-

regulating and the thermostat is internally connected

to the valve. When thermostat dial is set to 350°F and

the oven is below setpoint, the valve opens to allow

gas flow and burner lights. As the oven temperature

rises, the pressure from the sensor bulb in the oven

increases. Fluid in the capillary tube expands with the

temperature increase and presses against a

diaphragm in the thermostat. When the oven

temperature reaches setpoint, the internal valve

closes to stop gas flow to burner.

When the oven temperature decreases below

setpoint, the pressure is reduced in the capillary which

reduces the force on the diaphragm allowing the valve

to open again.

Adjustment

1. Place a thermocouple temperature probe (type K

preferred) in center of oven to verify actual

temperatures throughout adjustment.

2. Turn power switch on.

3. Turn thermostat knob to 350°F and allow oven to

cycle 3 complete times. If the customer has a

preferred temperature setting that they always

operate the oven at such as 325°, 375° or 400°,

you may calibrate to that temperature instead.

4. Take a temperature reading. If actual

temperature is more than 20° from knob setting,

calibrate as follows:

A. Pull off knob. Do not rotate knob during

removal.

Do not turn the adjustment screw more

than 3/8 turn or damage to the thermostat may occur.

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - SERVICE PROCEDURES AND

ADJUSTMENTS

F45471 Rev. A (0615) Page 30 of 38