B. Blower high speed (15 sec. time delay) -

Vacuum pressure should be 1.91" W.C. to

1.98" W.C.

C. If vacuum pressure reading is outside of the

values stated above, check blower air inlet

for debris buildup/obstructions. If found, turn

power switch off. Remove debris and retest.

D. If vacuum pressure results are the same

after retest, replace blower. Perform GAS

VALVE/BLOWER INLET PRESSURE

CHECK.

GAS VALVE/BLOWER INLET

PRESSURE CHECK

Shut off the gas before servicing the

unit.

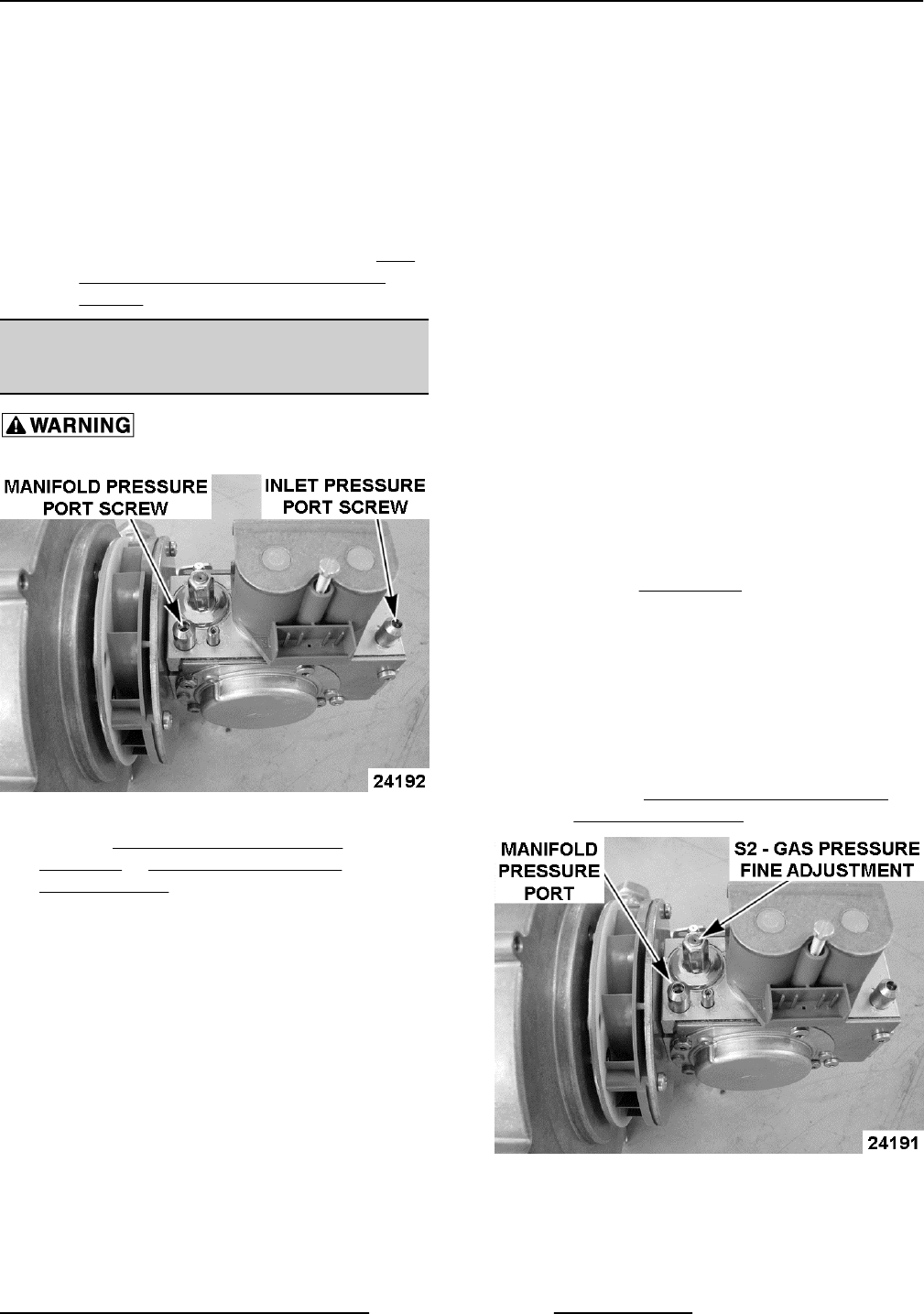

Fig. 40

1. Remove CORNER & REAR PANELS

(TILTING) or SIDE & REAR PANELS

(STATIONARY) to access blower & gas valve.

2. Open inlet pressure port. Turn screw 1 to 2 turns

CCW.

3. Attach slack tube manometer hose to inlet

pressure port.

4. Open manifold pressure port. Turn screw 1 to 2

turns CCW.

5. Attach U inclined manometer hose to manifold

pressure port.

6. Reconnect power and turn gas supply on.

NOTE: If static line pressure exceeds 14" W.C. (½

psig) the customer must supply and install a line

pressure regulator to reduce the pressure below the

maximum allowable for the valve.

7. Turn Kettle on.

8. Verify inlet pressure is 5-7" W.C. (natural) and

11-13" W.C. (propane).

9. Measure vacuum pressure.

A. Blower low speed (during trial for ignition, 7

sec) - Vacuum pressure reading should be

0.27" W.C. to 0.30" W.C. (natural or

propane).

B. Blower high speed (15 sec. time delay) -

Vacuum pressure should be 1.91" W.C. to

1.98" W.C. (natural or propane).

C. If vacuum pressure reading is outside of the

values stated above then manifold pressure

adjustment is required.

To Adjust:

1. Turn S2 gas pressure fine adjustment screw 1/4

turn (CW to increase; CCW to decrease).

2. Turn power switch off then back on and check

pressure readings. Repeat adjustment as

required.

A. If unable to achieve correct pressure, then

replace GAS VALVE. Preset S2 - gas

pressure fine adjustment screw on the

replacement valve. Turn screw fully

clockwise until it stops.

Natural - Turn screw 15 turns

counterclockwise.

Propane - Turn screw 9 turns

counterclockwise.

B. Perform GAS VALVE/BLOWER INLET

PRESSURE CHECK.

Fig. 41

K Series Gas Kettles 2/3 Jacketed Stationary and Tilting - SERVICE PROCEDURES AND ADJUSTMENTS

Page 23 of 44 F45461 Rev. A (0713)