C-5

Gas Instructions

Safe handling tips for Liquid Propane

Gas Cylinders

■ Liquid Propane (LP) gas is a petroleum product as are

gasoline and natural gas. LP gas is a gas at regular

temperatures and pressures. Under moderate pressure,

inside a cylinder, LP gas is a liquid. As the pressure is

released, the liquid readily vaporizes and becomes gas.

■ LP gas has an odor similar to natural gas. You should

be aware of this odor.

■ LP gas is heavier than air. Leaking LP gas may collect

in low areas and prevent dispersion.

■ To fill, take the LP cylinder to an RV center, or look up

“gas-propane” in the phone book for other sources of

LP gas.

ƽ WARNING: We recommend that your LP cylinder be

filled at an authorized LP gas dealer, by a qualified

attendant, who fills the tank by weight. IMPROPER

FILLING IS DANGEROUS.

ƽ WARNING: If you exchange your LP cylinder, make

sure you get a similar tank in return. Your LP

cylinder is equipped with a quick closing coupling

or type 1 valve and an OPD (Overfilling Prevention

Device). Other LP cylinders may not be compatible

with your barbecue connection.

■ Air must be removed from a new LP cylinder before the

initial filling. Your LP dealer is equipped to do this.

■ The LP cylinder must be installed, transported and

stored in an upright position. LP cylinders should not be

dropped or handled roughly.

■ Never store or transport the LP cylinder where

temperatures can reach 125° F (too hot to hold by hand

- for example: do not leave the LP cylinder in a car on a

hot day).

Note - A refill will last about 20 hours of cooking time at

normal use. The fuel scale will indicate the propane supply

so you can refill before running out. You do not have to run

out before you refill.

■ Treat “empty” LP cylinders with the same care as when

full. Even when the LP tank is empty of liquid there still

may be gas pressure in the cylinder. Always close the

cylinder valve before disconnecting.

ƽ CAUTION: When transporting the LP cylinder make

sure the plastic dust cover is in place over the

valve. This will keep dust and dirt from the threaded

portion of the valve.

■ Do not use a damaged LP cylinder. Dented or rusty LP

cylinders or LP cylinders with a damaged valve may be

hazardous and should be replaced with a new one

immediately.

Liquid Propane (LP) Cylinder(s)

■ The joint where the hose connects to the LP cylinder

must be leak tested each time the LP cylinder is

reconnected. For example, test each time the LP

cylinder is refilled.

■ Be sure the regulator is mounted with the small vent

hole pointed downward so that it will not collect water.

This vent should be free of dirt, grease, bugs etc.

■ The LP cylinder and connections supplied with your

Weber

®

gas barbecue have been designed and tested

to meet government, American Gas Association, and

Underwriters Laboratories requirements.

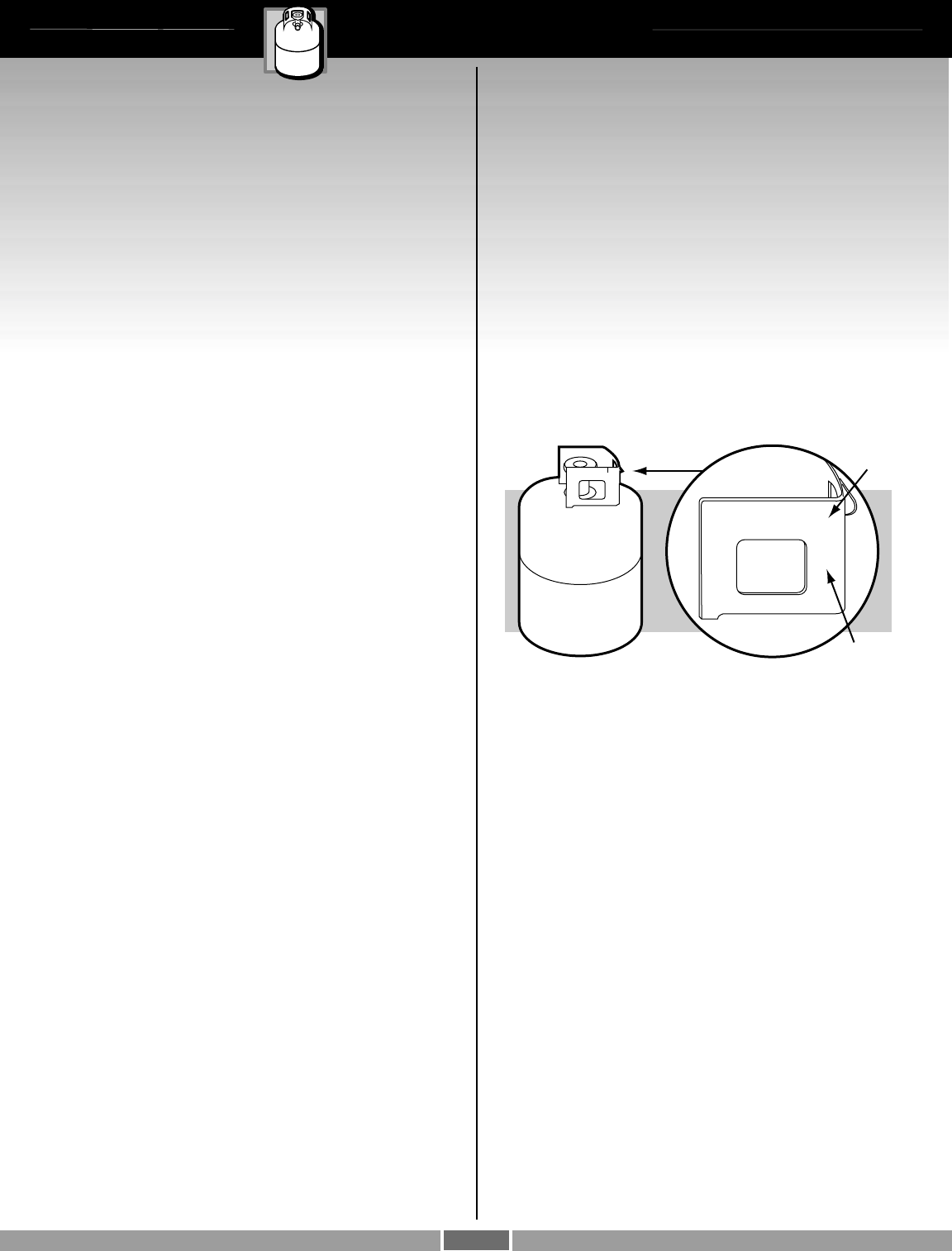

Liquid Propane Cylinder requirements

■ Replacement LP cylinders supplied by Weber satisfy

the above requirements. Check to be sure other

cylinders have a D.O.T. certification(1), and date

tested(2) is within five years. Your LP gas supplier can

do this for you.

If you have questions about spare LP cylinders

contact the Customer Service Representative in your

region using the contact information sheet provided

with your manual.

■ All LP tank supply systems must include a collar to

protect the cylinder valve.

■ The LP cylinder must be a 20-lb. size (18 1/4 inches

high, 12 1/4 inches in diameter).

■ The LP cylinder must be constructed and marked in

accordance with the specifications for LP gas cylinders

of the U.S. Department of Transportation (D.O.T.).

For Canada Only

Liquid Propane Cylinder requirements

ƽ WARNING: Replacement LP tanks must match the

regulator connection supplied with this barbecue.

Note: Your retailer can help you match a replacement tank

to your barbecue

■ All LP tank supply systems must include a collar to

protect the cylinder valve.

■ The LP cylinder must be a 20-lb. size (18 1/4 inches

high, 12 1/4 inches in diameter).

■ The LP cylinder must be constructed and marked in

accordance with the specifications for LP gas cylinders,

T.C.

DOT 4BA240

00/01

(1)

(2)