5

INSTALLATION (continued)

WARNING: Electric Shock hazard

All servicing requiring access to non-insulated electrical components must be

performed by a factory authorized technician.

DO NOT open any access panel which requires the use of tools. Failure to follow this

warning can result in severe electrical shock.

CAUTION:

Risk of

Damage

DO NOT connect or energize

this appliance until all

installation instructions are

read and followed. Damage

to the appliance will result if

these instructions are not

followed.

CAUTION:

Electrical Shock

Hazard

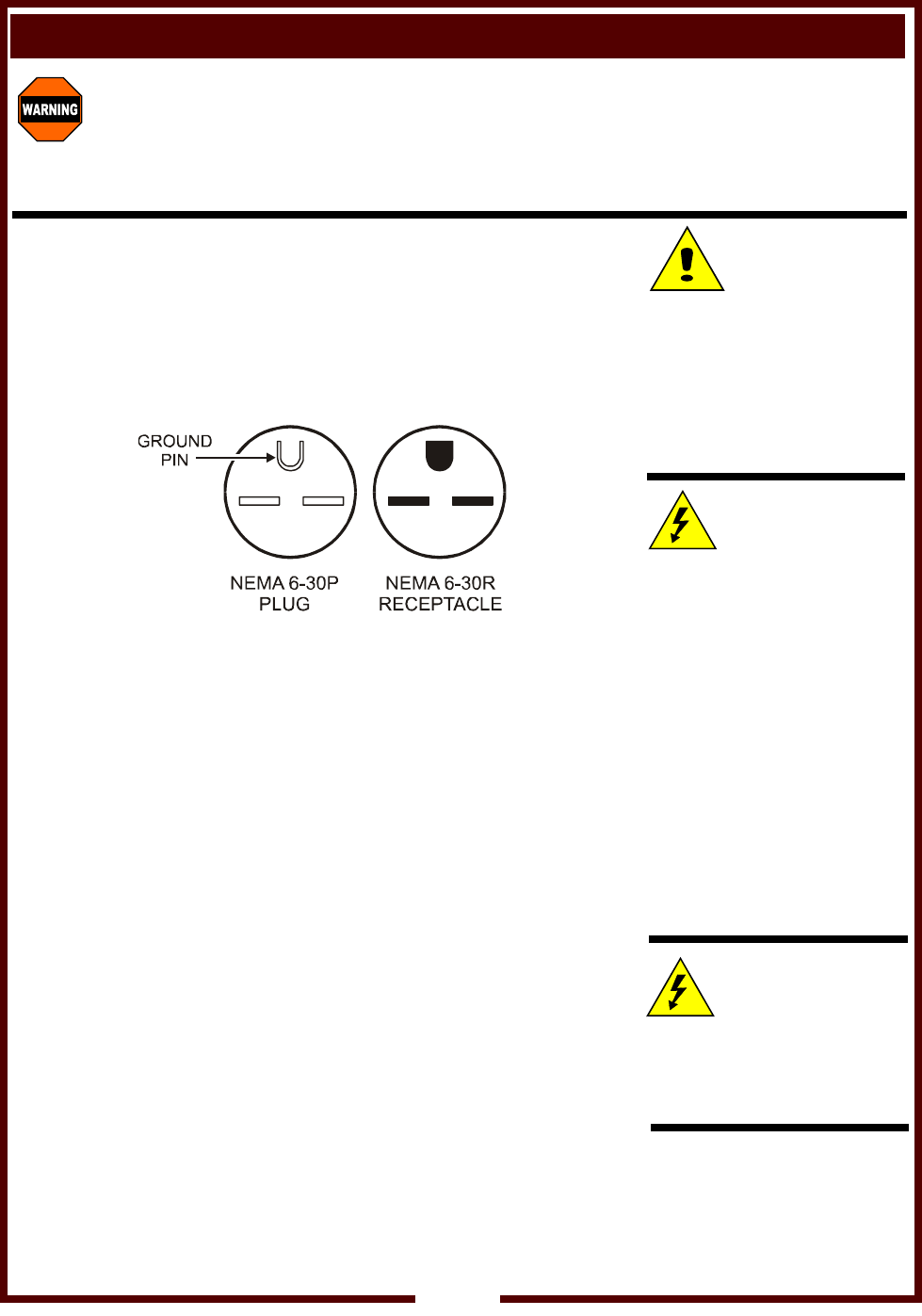

The ground pin of the power

cord plug is part of a system

designed to protect you from

electric shock in the event of

equipment damage.

DO NOT cut the ground pin

from the power cord plug in

order to fit an existing

receptacle;

DO NOT twist a blade of the

power cord plug in order to fit

an existing receptacle.

Contact a licensed electrician

to install an appropriate

electrical circuit and

receptacle.

CAUTION:

Electrical Shock

Hazard

The ground lug of F-55 and

F-67 fryers must be

connected to a suitable

building electric ground.

IMPORTANT:

Damage due to being

connected to the wrong

voltage or phase is NOT

covered by warranty.

F-49 FRYER ELECTRICAL INSTALLATION

This fryer is equipped with a cord and NEMA 6-30P plug, and requires

a properly installed NEMA 6-30R receptacle. Contact a licensed

electrician to install an appropriate 208 VAC or 240 VAC 30 amp

electric circuit and grounded receptacle.

Be sure the TEMPERATURE CONTROL KNOB is turned to the OFF

position, then plug the POWER CORD into a matching receptacle.

F-55 FRYER ELECTRICAL INSTALLATION

F-55 fryers must be connected directly to the electric circuit. Conduit

and strain relief must be provided by the electrician. F-55 fryers require

a 208VAC or 240VAC 40 amp circuit with ground.

Raise the element head, remove the frypot and the cover at the rear of

the fryer to gain access to the terminal block. The electrical inlet is

provided by a knock-out in the rear panel.

If an equipment shutdown interface is required by local fire code, the

flame sensor terminal block may be accessed by removing the back

panel. Replace the jumper of the terminal block with wiring to a

normally closed contact of the building fire management system.

DO NOT connect power to the flame sensor terminal block. Wiring and

contacts must be capable of handling 30 amps.

F-67 FRYER ELECTRICAL INSTALLATION

F-67 fryers must be connected directly to the electric circuit. Conduit

and strain relief must be provided by the electrician. F-67 fryers require

either a 208VAC or 240VAC 50 amp single phase circuit with ground;

or, a 208VAC or 240VAC 40 amp three phase circuit with ground. Units

are shipped from the factory wired for three phase. Conversion to

single phase must be performed in the field by the electrician.

Raise the element head, remove the frypot and the cover at the rear of

the fryer to gain access to the terminal block. The electrical inlet is

provided by a knock-out in the rear panel.

Fig. 3 F-49 Fryer Power Plug and Receptacle Configuration