INSTALL LOOSE PARTS

ICE THICKNESS

.

FLOAT

WATER LEVEL

ADJUSTMENT / ’ ;;lER PUMP

\’

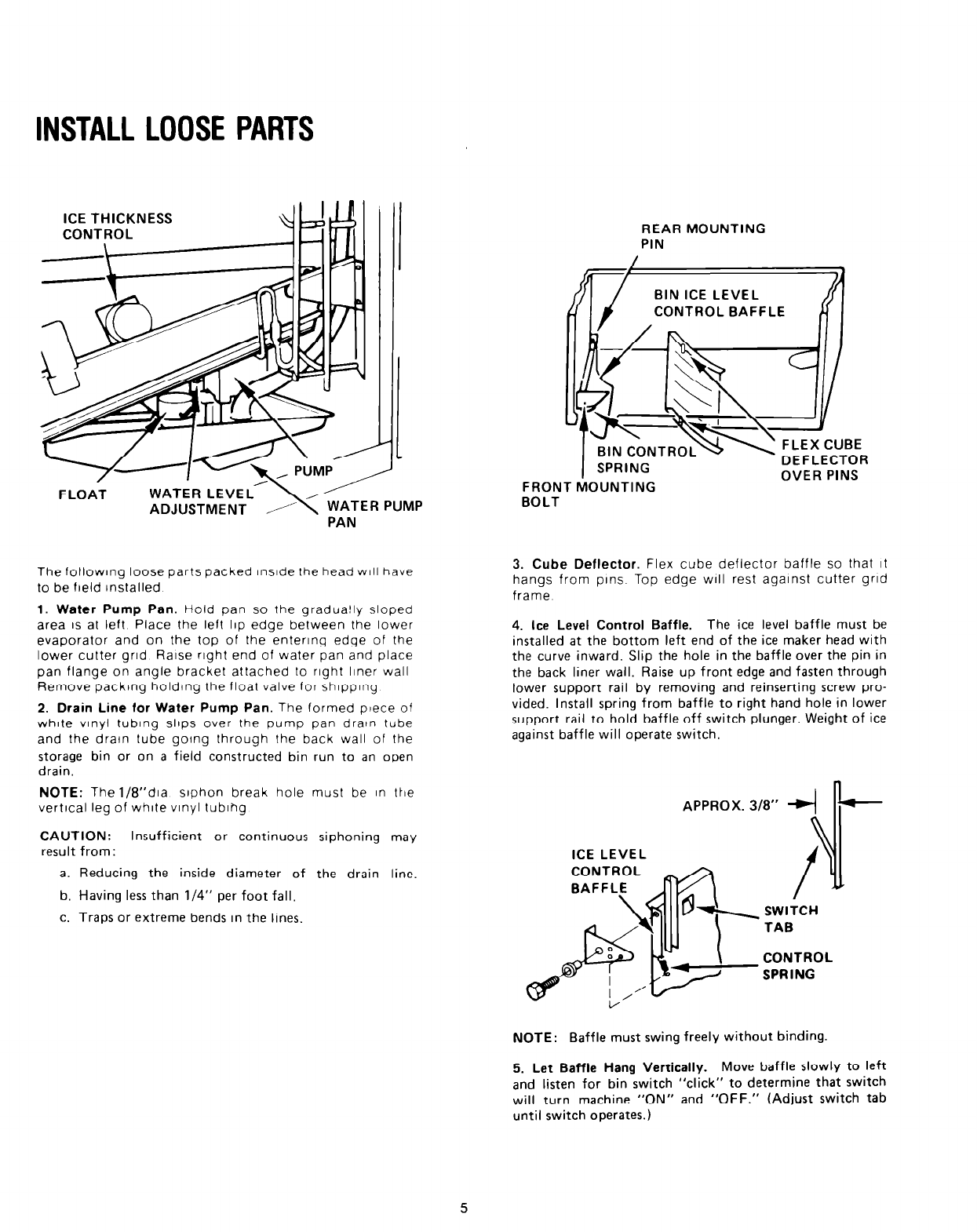

The following loose parts packed InsIde Ihe head WIII have

to be field Installed

1. Water Pump Pan. Hold pan so the gradua!ly sloped

area IS at left Place the left 11p edge between the lower

evaporator and on the top of the entering edge of the

lower cutter grid Raise right end of water pan and place

pan flange on angle bracket attached to right liner wall

Remove packing holding the float valve for shlpplng

2. Drain Line for Water Pump Pan. The formed piece of

white vlnyl tubing slips over the pump pan drawn tube

and the drain lube going through the back wall of the

storage bin or on a field constructed bin run to an open

drain.

NOTE: The 1/8”dia siphon break hole must be In IIle

vertical leg of white vinyl tubing

CAUTION: Insufficient or continuous siphoning may

result from:

a. Reducing the inside diameter of the drain line.

b. Having less than l/4” per foot fall,

c. Traps or extreme bends in the lines.

FRON

BOLT

REAR MOUNTING

PIN

T hhl

SPRING

3UNTING

- DEFLECTOR

OVER PINS

3. Cube Deflector. Flex cube deflector baffle so that it

hangs from pins. Top edge will rest against cutter grid

frame

4. Ice Level Control Baffle. The ice level baffle must be

installed at the bottom left end of the ice maker head with

the curve inward. Slip the hole in the baffle over the pin in

the back liner wall. Raise up front edge and fasten through

lower support rail by removing and reinserting screw pro-

vided. Install spring from baffle to right hand hole in lower

support rail to hold baffle off switch plunger. Weight of ice

against baffle will operate switch.

APPROX. 318”

+I”-

SWITCH

TAB

CONTROL

SPRING

NOTE: Baffle must swing freely without binding.

5. Let Baffle Hang Vertically. Move baffle slowly to left

and listen for bin switch “click” to determine that switch

will turn machine “ON” and “OFF.” (Adjust switch tab

until switch operates.)

5