Cleaning and caring for your ice maker

Periodically inspect and clean the ice

maker to keep it operating at peak efficiency

and to prevent premature failure of system

components.

Both the ice making system and the air cooled

condenser need to be cleaned regularly.

The minerals rejected from the circulating

water during the freezing cycle will eventually

form a hard scaly deposit in the water system

which prevents a rapid release of the ice from

the freezing plate.

Cleaning exterior surfaces

Wash the exterior enamel surfaces and

gaskets with warm water and mild soap or

detergent. Rinse and dry. Regular use of

a good household appliance cleaner and

wax will help protect the finish.

Do not use harsh or abrasive cleaners on

enamel surfaces as they may scratch the

finish.

Cleaning the condenser

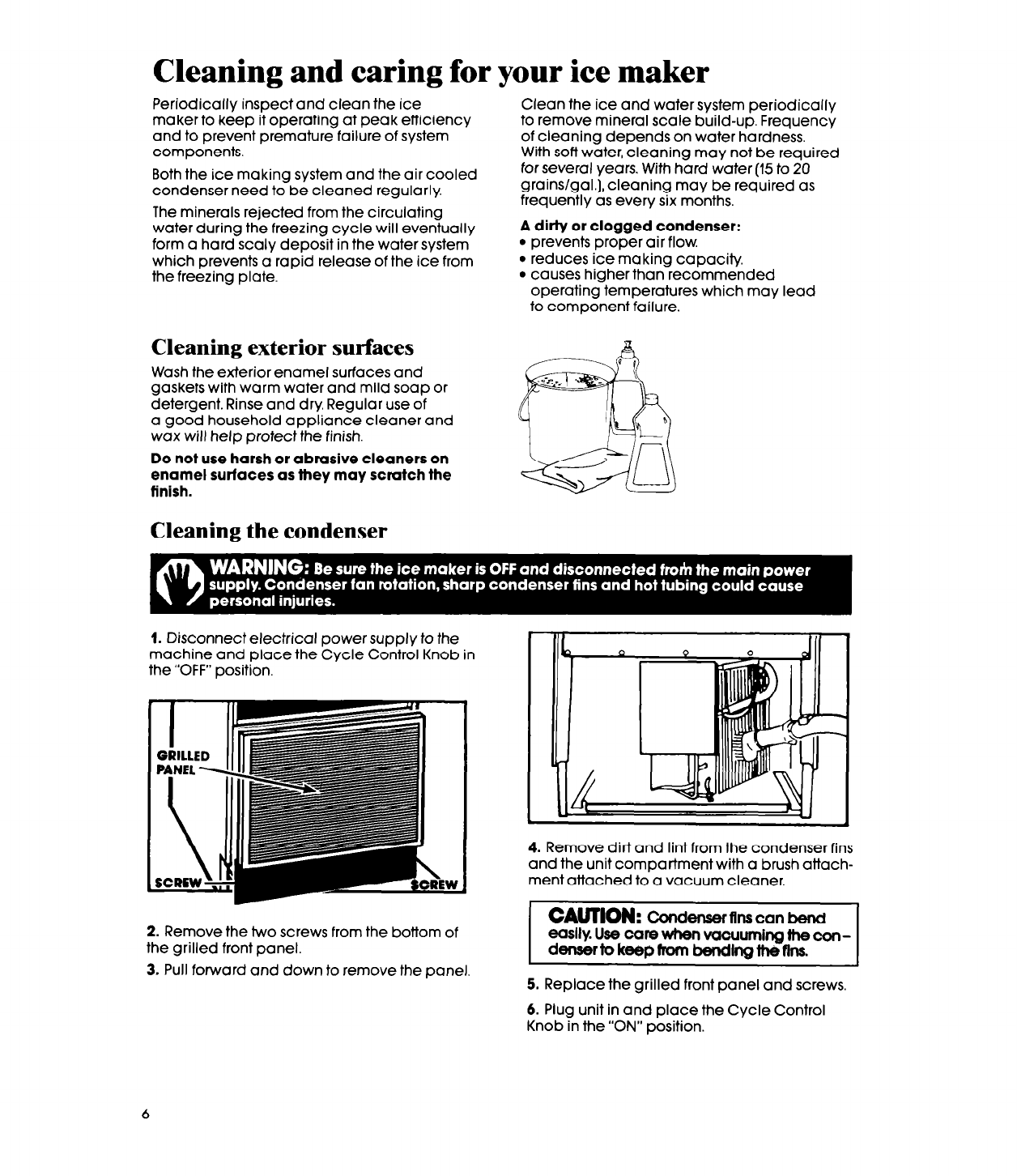

1. Disconnect electrical power supply to the

machine and place the Cycle Control Knob in

the “OFF” position.

Clean the ice and water system periodically

to remove mineral scale build-up. Frequency

of cleaning depends on water hardness.

With soft water, cleaning may not be required

for several years. With hard water (15 to 20

grains/gal.), cleaning may be required as

frequently as every six months.

A dirty or clogged condenser:

l

prevents proper air flow.

l

reduces ice making capacity.

l

causes higher than recommended

operating temperatures which may lead

to component failure.

1

L

4. Remove dirt and lint from the condenser fins

and the unit compartment with a brush attach-

ment attached to a vacuum cleaner.

I

I

5. Replace the grilled front panel and screws.

CAUTION:

~ondense~ns can bend

easily. use care when vacuuming ltle con -

densertokeepfrombendinglheflns.

2. Remove the two screws from the bottom of

the grilled front panel.

3. Pull forward and down to remove the panel.

6. Plug unit in and place the Cycle Control

Knob in the “ON” position.