12

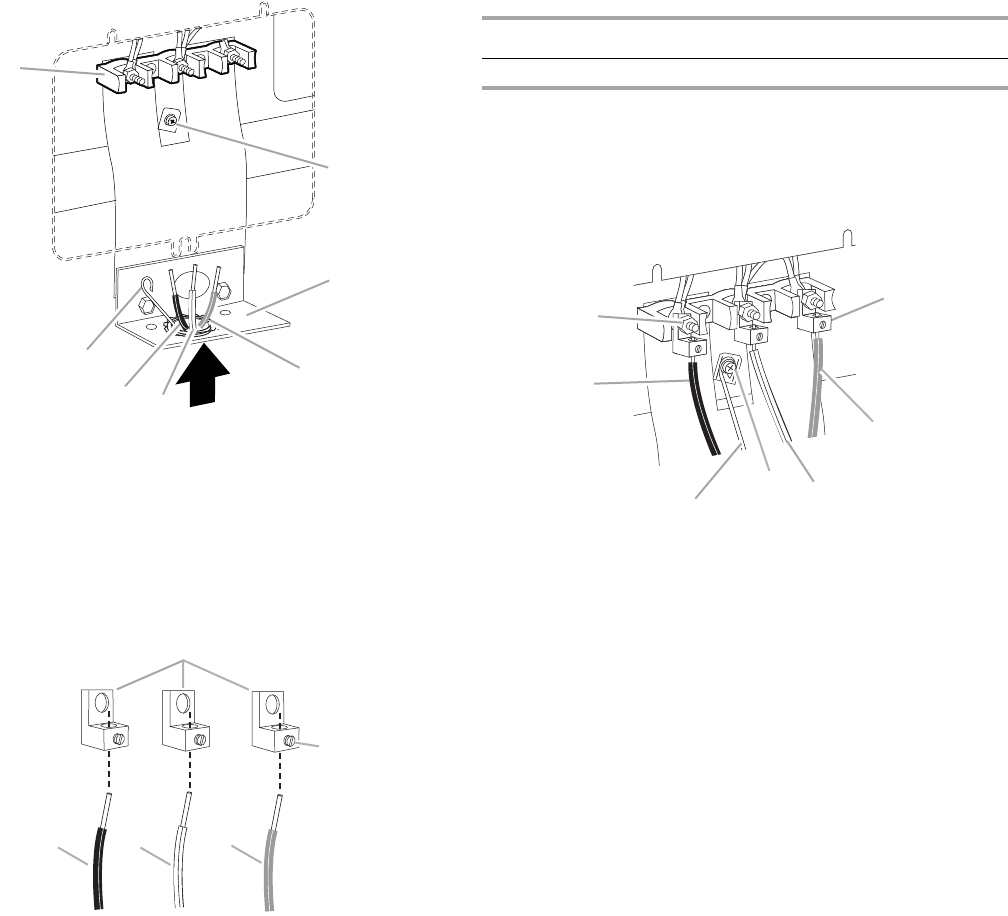

3. Pull the conduit through the strain relief on cord/conduit plate

on bottom of range. Allow enough slack to easily attach wiring

to the terminal block.

4. Attach terminal lugs to line 1 (black), neutral (white), and line

2 (red) wires. Loosen (do not remove) the setscrew on the front

of the terminal lug and insert exposed wire end through

bottom of terminal lugs. Securely tighten setscrew to

XX lbs-in. torque. See Bare Wire Torque Specifications chart.

Bare Wire Torque Specifications

Attaching terminal lugs to the terminal block - 20 lbs-in. (2.3 N-m)

5. Use Phillips screwdriver to connect the bare (green) ground

wire to the range with the ground-link screw. The ground wire

must be attached first and must not contact any other

terminal.

6. Use ³⁄₈" nut driver to connect the neutral (white) wire to the

center terminal block post with one of the 10–32 hex nuts.

7. Connect line 1 (black) and line 2 (red) wires to the outer

terminal block posts with 10-32 hex nuts.

8. Securely tighten hex nuts.

9. Replace terminal block access cover.

A.Terminal block

B.Ground-link screw

C.Cord/conduit plate

D.Line 2 (red) wire

E.Neutral (white) wire

F. Line 1 (black) wire

G.Bare (green) ground wire

A.Terminal lug

B.Setscrew

C.Line 1 (black) wire

D.Neutral (white) wire

E.Line 2 (red) wire

A

B

C

D

E

F

G

A

B

C

DE

Wire Awg Torque

8 gauge copper 25 lbs-in. (2.8 N-m)

6 gauge aluminum 35 lbs-in. (4.0 N-m)

A.10–32 hex nut

B. Line 1 (black)

C.Bare (green) ground wire

D.Ground-link screw

E.Neutral (white) wire

F. Line 2 (red)

G.Terminal lug

B

A

G

E

C

D

F