2

WIRING

SETTING THE DIAL

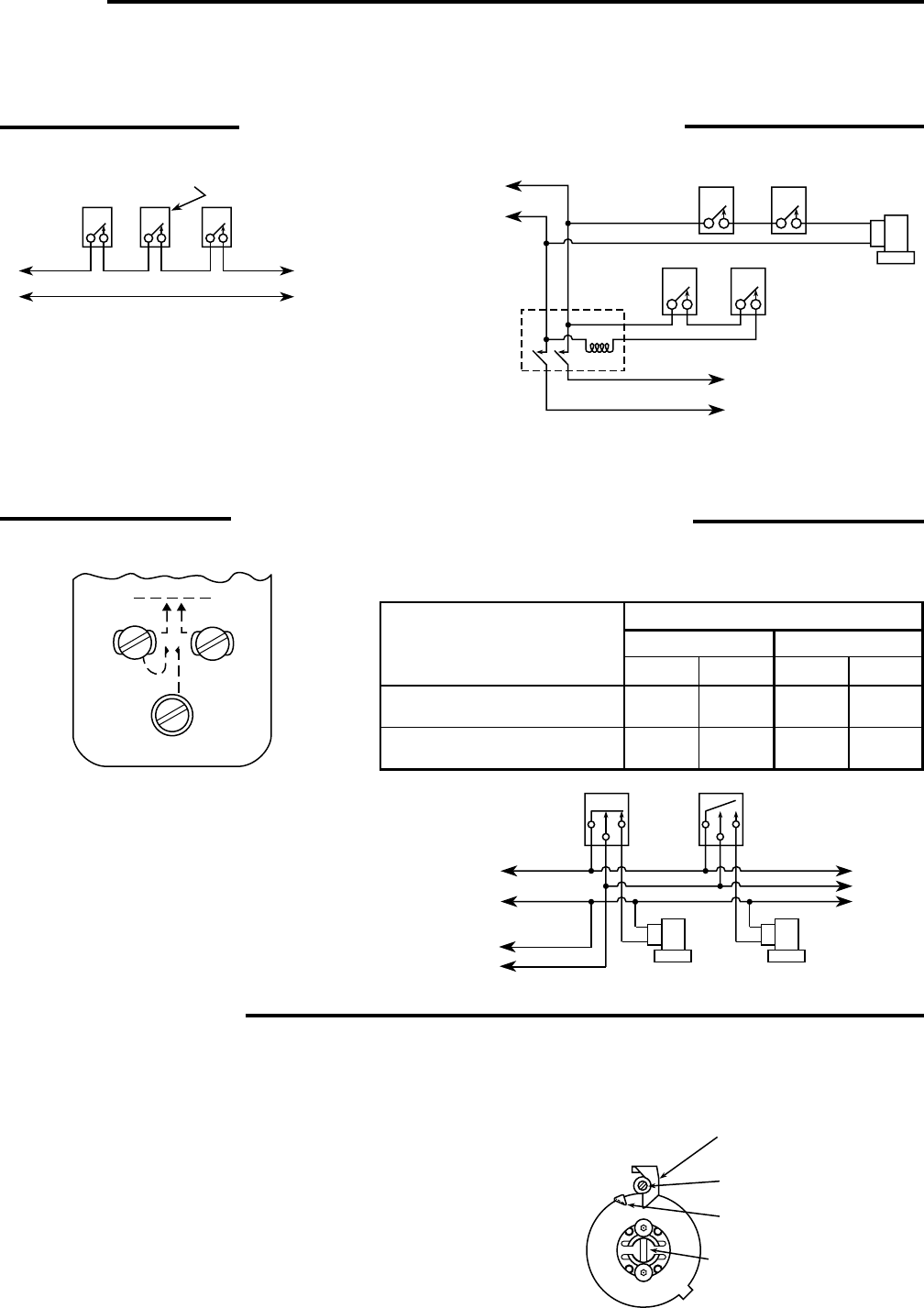

All wiring must conform to local and national electrical codes and ordinances.

Connect in accordance with wiring diagrams provided by the equipment manufacturer. If none are provided, the following

represents a typical installation.

The movable indicator (D) points to the temperature at which the

compressor starts. The fixed indicator (B) points to the tempera-

ture at which the compressor will stop. The difference between

these two indicators is the differential. Follow these instructions

to set the dial:

1. Insert a screwdriver in the adjusting slot (A) and turn the dial

until the fixed indicator (B) points to the temperature at which

the compressor is to stop.

Temperature

control

Low

temperature

limit

High side

pressure control

(if used)

To

Compressor

Motor

Line

L1

L2

Note:Make L1 “HOT” on

120V installation

Circuit showing temperature control con-

trolling compressor directly.

Temperature

control

Low temperature

limit

Suction

pressure

control

High side

pressure

control

Motor

starter

Solenoid

refrigerant

valve

To

Compressor

Motor

Line

L1

L2

Note:Make L1 “HOT” on

120V installation

Circuit showing temperature control to open and close

refrigerant valve. Suction pressure control starts and stops

compressor through motor starter.

“B” Fixed indicator

(cut-out point)

“C” Differential

adjusting screw

“D” Movable indicator

(cut-in point)

“A” Adjusting

slot

Controls with one circuit (two terminals)

Controls with two circuits (three terminals)

BLUE

RED

WHITE

240V

22.2A

22.2A

LOAD CONDITIONS

MAXIMUM ALLOWABLE RATING

Full Load Locked Rotor

120V

7.4A

7.4A

120V

44.5A

44.5A

240V

3.7A

3.7A

Load between Blue and Red

terminals must not exceed:

Load between Blue and White

terminals must not exceed:

To

Additional

Units

B

R

W

B

R

W

Valve

No. 2

Valve

No. 1To

Compressor

Motor

Line

L1

L2

Note:Make L1 “HOT” on

120V installation

This diagram shows a typical two-circuit applica-

tion. Several zones receive refrigeration from the

same compressor, but each zone requires its

own solenoid refrigerant valve and temperature

control.

The blue terminal is common. The table below shows the

maximum load allowed between terminals.

2. Turn the differential adjusting screw (C) until the movable

indicator (D) points to the temperature at which the com-

pressor is to start.