FULL SIZE GAS CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

F32700 (February 2006)Page 21 of 64

5. Reverse procedure to install.

TEMP (°F) OHMS* TEMP (°F) OHMS*

77 90000 360 822

240 4077 380 656

260 3016 400 529

280 2266 425 424

300 1726 450 334

320 1332 475 266

340 1041

(*) Resistance in ohms ± 10%

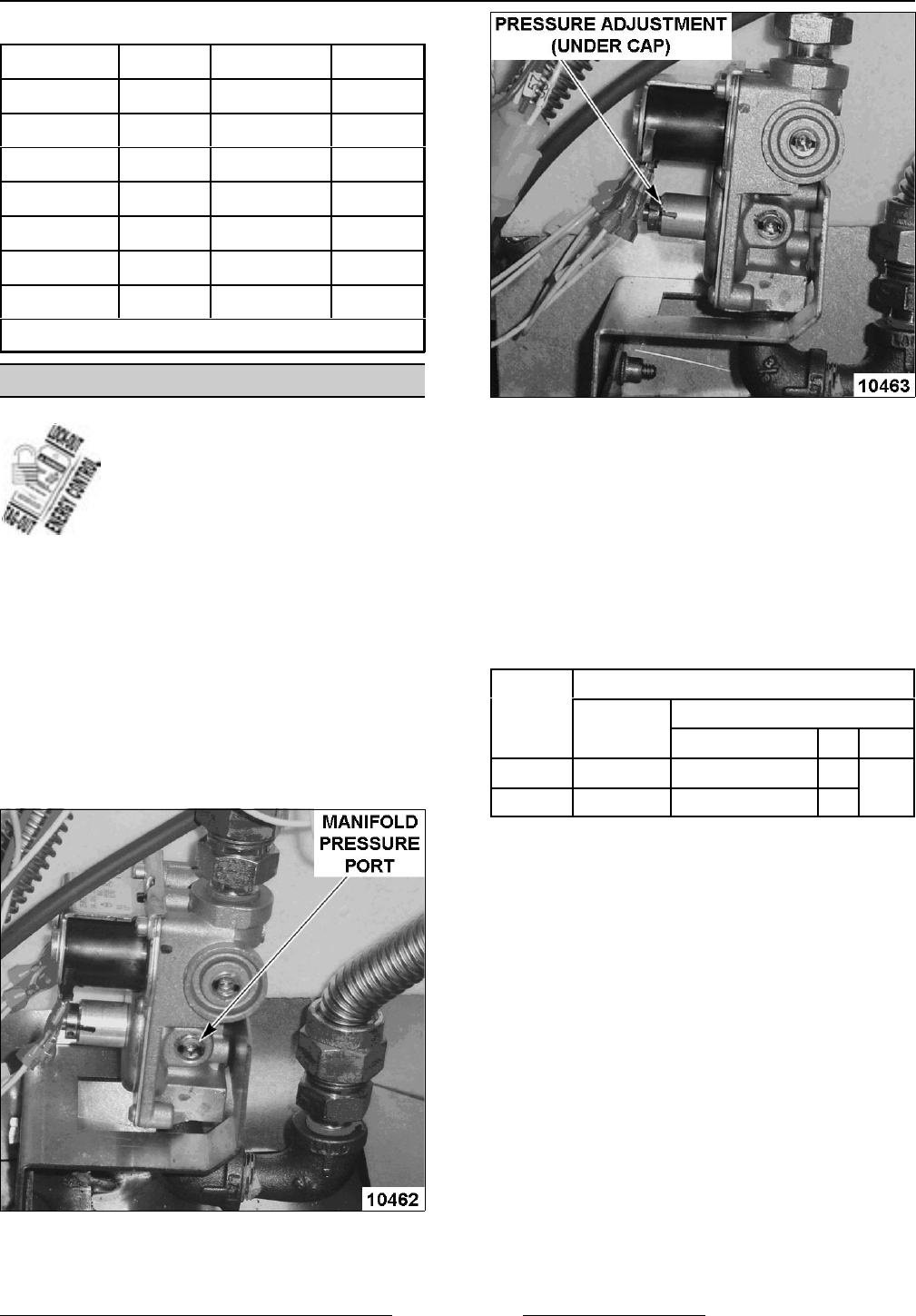

GAS PRESSURE ADJUSTMENT

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

1. Remove the right side panel as outlined under

COVERS AND PANELS in REMOVAL AND

REPLACEMENT OF PARTS.

NOTE: If right side panel is not accessible, this

component can be serviced by removing the control

panel as outlined under COVERS AND PANELS.

2. Remove the plug from the manifold pressure

port.

3. Install hose barb adapter and attach manometer

tube.

4. Remove adjustment screw cap from the gas

valve and turn gas supply to the oven back on.

5. Plug the unit in and turn the power switch ON.

6. Set the temperature control to its highest setting

and allow burner to ignite.

NOTE: Accurate gas pressure adjustments can only

be made with the gas on and the burner lit.

7. Turn the set screw to obtain the proper gas

pressure (clockwise = pressure increase;

counterclockwise = pressure decrease).

GAS

TYPE

PRESSURE READINGS (IN W.C.)

MANIFOLD

LINE

RECOMMENDED MIN MAX

Natural

3.5 7 5

14

Propane

10 11 11

NOTE: If the incoming line pressure to the valve is

less than the minimum stated, then the manifold

pressure can not be set correctly.