Kitchen or Internal Space Air Supply

Where the appliance is to be installed in a kitchen or

internal space, it does not require the kitchen or internal

space containing it to have a permanent air vent.

Installation pipes should be fitted in accordance with

current Gas Regulations. Pipework from the meter/tank to

the cooker must be of adequate size, cooker connection

size of 15mm Dia. On completion test the gas installation

for soundness and purge in accordance with current Gas

Regulations.

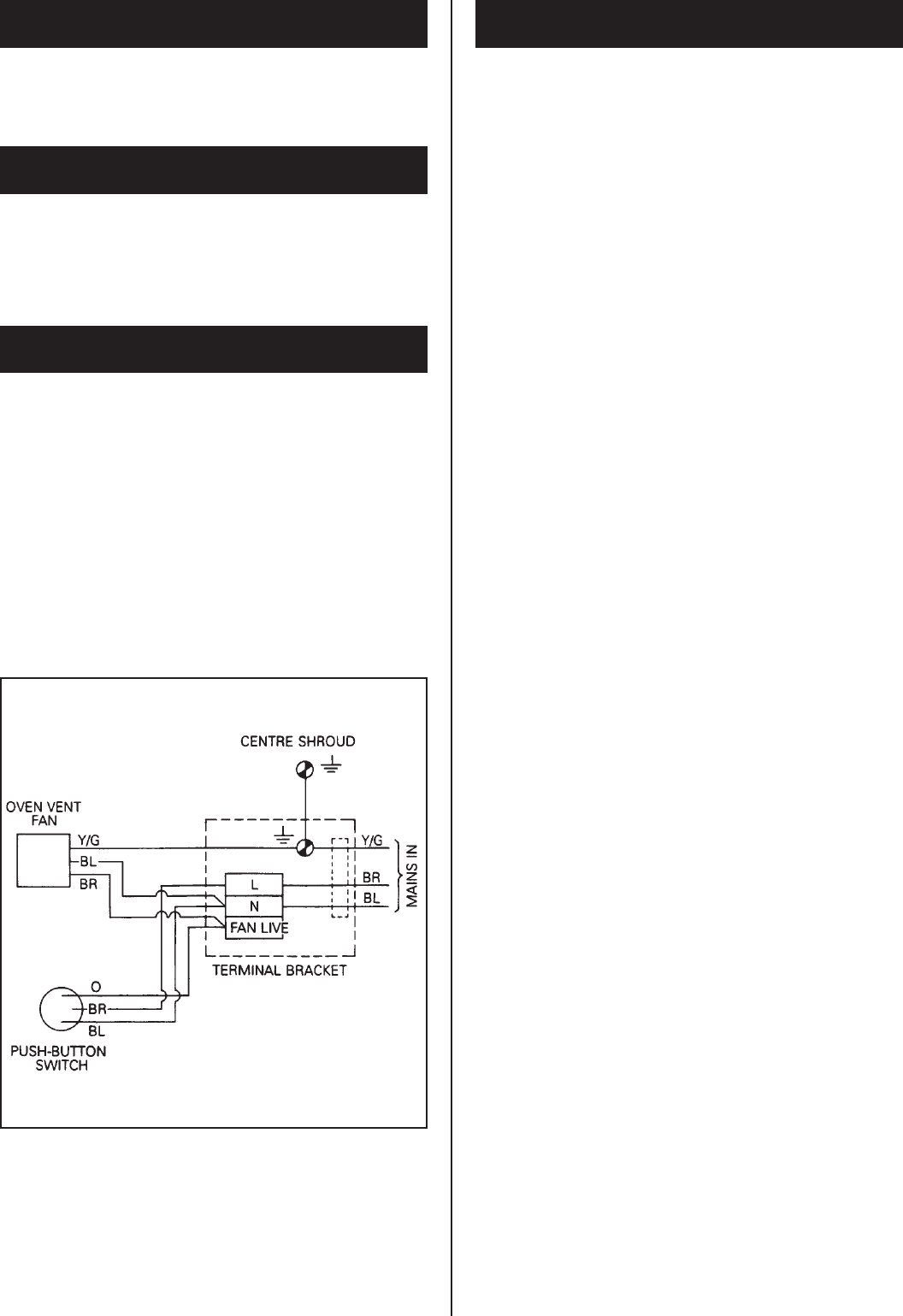

A 3Amp 230V~50Hz fused electrical supply is required

adjacent to the appliance. External wiring to the fan unit

must be installed using a 3 core heat resisting 85°C PVC

sheathed cable and in accordance with the current Wiring

Regulations and any local regulations which apply. The

wiring should be completed as indicated:

The method of connection to the mains electricity supply

must facilitate complete electrical isolation of the

appliance, preferably by the use of an unswitched

shuttered socket outlet in conjunction with a fused three

pin plug. Alternatively, a fused double pole switch, having

a contact separation of at least 3mm in both poles, serving

only the appliance may be used.

(Models GCB and GEB Only)

In a domestic hot water system, the hot water storage

vessel must be of the indirect cylinder of calorifier type.

The hot water storage vessel should be insulated,

preferably, with not less than 75mm thick mineral fibre, or

its equivalent.

Pipework not forming part of the useful heating surface

should be insulated to help prevent heat loss and possible

freezing, particularly where pipes are run through roof

spaces and ventilated under floor spaces. Cisterns

situated in areas which may be exposed to freezing

conditions should also be insulated.

Draining taps must be located in accessible positions

which permit the draining of the whole system, including

the boiler and hot water storage vessel.

Draining taps should be at least 15mm nominal size. The

use of horizontal pipe runs should be avoided wherever

possible in order to prevent the collection of air in the

system. If horizontal runs are unavoidable, the pipes

should rise upwards in the direction away from the boiler.

Hot water systems should be in accordance with the

relevant recommendations.

Water Circulation System

(Models GCB and GEB only)

The cooker boiler should be connected to a cistern water

supply and subject to a maximum head of 18.25m and

minimum 1m.

The 28mm minimum diameter primary flow pipe must rise

continuously from the cooker boiler to the cylinder to

ensure good gravity circulation and have an open vent.

The 28mm diameter primary flow and return pipes must

not exceed 5.5m in length and be well insulated.

Water Connections

(Models GCB and GEB only)

The two 28mm copper flow and return pipes from the

boiler can be obtained for right or left hand connections.

Hot Water Storage Vessel

It is recommended that an indirect 190 litre (40 gallon) hot

water storage cylinder of the double feed type should be

lagged and fixed vertically as near as possible to the

cooker.

The water draw-off pipes to the taps must be dead leg

connection from the vent/expansion pipe.

A drain tap must be fitted at the lowest point of the

system.

Cooker Boiler Heat Exchanger

The heat exchanger must be connected to a 190 litre (40

gallon) copper double feed indirect cylinder.

THE HOT WATER SYSTEM

5

INSTALLATION PIPES

ELECTRICAL

AIR SUPPLY