13

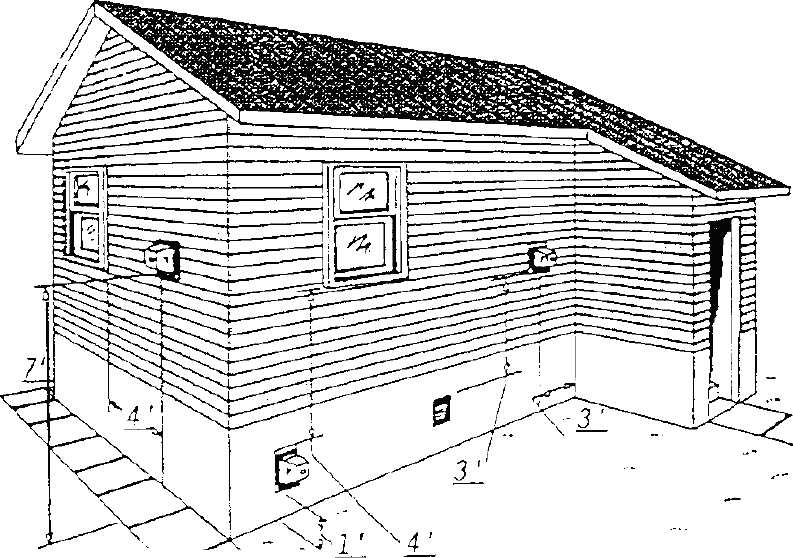

3. COMBINATION AIR INTAKE/VENT SYSTEM

The vent system consists of 10, 15, or 20 foot lengths of 5” single wall flexible stainless vent piping, or

10 or 15 foot lengths of double wall insulated flexible stainless vent piping and an equal length of 4” air

intake piping and a stainless steel intake/vent termination end.

Consult the Direct Vent manual included with the direct vent kit

for more detailed installation instructions.

The hole thru the wall for the vent termination end should be ¼” larger than the vent termination end

itself or approximately 7 ¼” square.

Install the vent termination thru the opening in the wall centering it in opening. Apply a bead of silicone

caulking around the perimeter of the vent termination end. Attach the termination to the house by

screwing it fast thru the holes in the termination end.

Install the flexible vent piping with the provided connector between the boiler and the termination end.

The joints at the boiler, vent connectors, and termination end should be securely fastened and must be

sealed with high temperature silicone to prevent leakage of flue gasses.

THE MINIMUM DISTANCE TO COMBUSTIBLE MATERIALS FROM THE 5” SINGLE

WALL VENT PIPING IS 9”. THE MINIMUM DISTANCE TO COMBUSTIBLE MATERIALS

FROM THE 5” DOUBLE WALL INSULATED VENT PIPING IS 2”. CONSULT NFPA-31

FOR REDUCED CLEARANCES.

The air intake must be installed to the air inlet collar on the combination vent hood and to the burner.

The air intake kit consists of one 4” galvanized elbow, one 4” galvanized tee, one vacuum relief valve

(barometric damper), and one length of 4” flexible piping.

The vacuum relief valve (barometric damper) is to be assembled and then installed in the 4” tee with the

hardware provided. Install the fresh air intake duct tee and damper as close as possible to the burner.