D. ELECTRICAL INSTALLATION

1. Refer to the nameplate on the front of the fryer. Verify the ELECTRICAL SERVICE POWER.

Voltage and phase must match the nameplate specifications, and available electrical service

amperage must meet or exceed the specifications listed on page 1.

Wiring must be no less than12 ga. solid copper wire, rated for at least 75ºC.

NOTE: Wire gauge, insulation type and temperature rating , as well as type, size and

construction of conduit, must meet or exceed applicable specifications of local codes and

of the National Electrical Code.

2. Fryers are shipped from the factory wired for 3Ø electrical service. Refer to theThree-Phase

Wiring Diagram included with this fryer, and verify that field wiring conforms to this diagram .

NOTE: FRYERS are FIELD CONVERTIBLE to 1Ø. If single-phase operation is required,

refer to the 3-phase to 1-phase Instructions included with the FRYER, and verify that both

internal wiring and field wiring conform to the included single-phase wiring diagram .

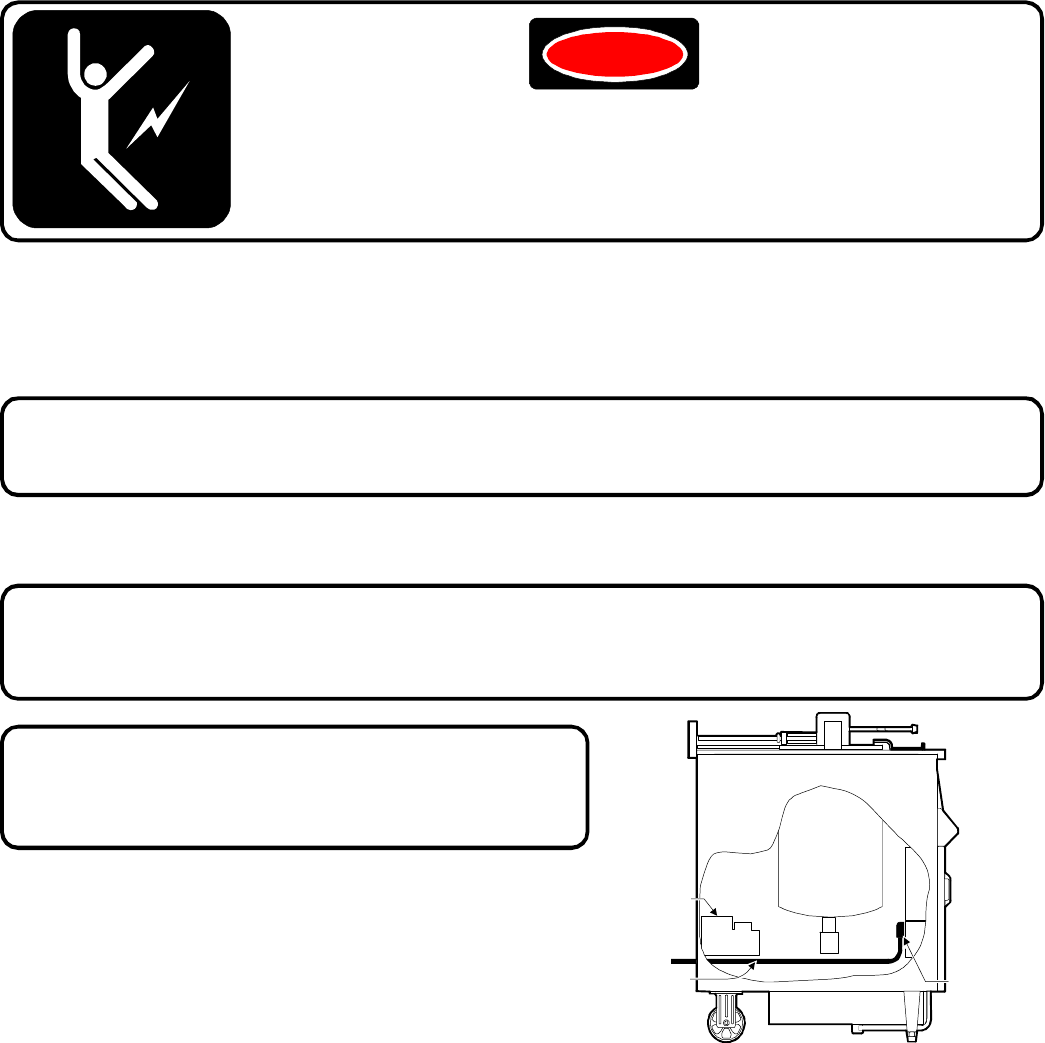

DANGER

ELECTRICAL SHOCK HAZARD

ELECTRICAL CONNECTIONS MUST BE MADE BY A LICENSED

ELECTRICIAN

Electrical shock will cause death or serious injury.

POWER

CORD

FRYPOT

90º

CONDUIT

FITTING

FILTER

PUMP &

MOTOR

6

IMPORTANT: Field wiring must be routed and

secured away from the FRYPOT, TUBING

and FILTER PUMP AND MOTOR.

C. EQUIPMENT SET-UP

1. Setup the FRYER only on a firm, level, non-combustable surface. Verify local codes for

requirements. Concrete, tile, terrazzo or metal surfaces are recommended. Metal over

combustible material may not meet code for non-combustible surfaces.

2. LEVELING: Verify that the fryer sits firmly ON BOTH CASTERS AND ON BOTH LEGS.

With a spirit level, check that the fryer is level front-to-back and side-to-side. With the

adjustable legs, adjust as required to level the fryer.

NOTE: Field wiring must allow access to the

rear of the FRYER for cleaning and for access

to the oil filter pump motor RESET BUTTON.