26 27

OPERATING YOUR BREVILLE PRODUCT OPERATING YOUR BREVILLE PRODUCT

Lock Hopper

Indicates if the bean hopper has not been

properly inserted and locked into position.

The auto grind, dose & tamp function cannot

be used during this time and 3 beeps will

sound if user attempts to activate.

Overheat Please Wait

Indicates if the grinder is used excessively

and needs time to cool. The auto grind, dose

& tamp function cannot be used during this

time and 3 beeps will sound if user attempts

to activate.

Change Filter

Indicates when the water filter in the water

tank needs to be replaced. For information

on changing the filter, refer to 'Installing

The Water Filter', page 34.

The regularity of this alert is determined

by the water hardness setting (Hrd1-Hrd5)

selected. For information, refer to 'Setting

Water Hardness', page 14 and 'Water

Hardness (Hrd3)', page 24.

TRANSPORTING AND STORING

We recommend draining both boilers

completely before transporting the machine

or storing for an extended period of time.

This procedure is also intended as an

anti-freeze measure in the event the machine

is exposed to extreme cold temperatures.

CAUTION

Never open DESCALE ACCESS valves

while machine is still hot. Always

turn off the machine and allow to cool

for at least 1 hour prior to starting

descale process.

CAUTION

During descale process, water may

flow through group head and the drip

tray will fill with water.

Step 1 – Preparation

a) Ensure the machine is off and has cooled

for at least 1 hour.

b) Empty water tank, remove water filter

then replace and lock water tank back

into position.

c) Ensure drip tray is empty and fully

inserted into position.

Step 2 – Empty Boilers

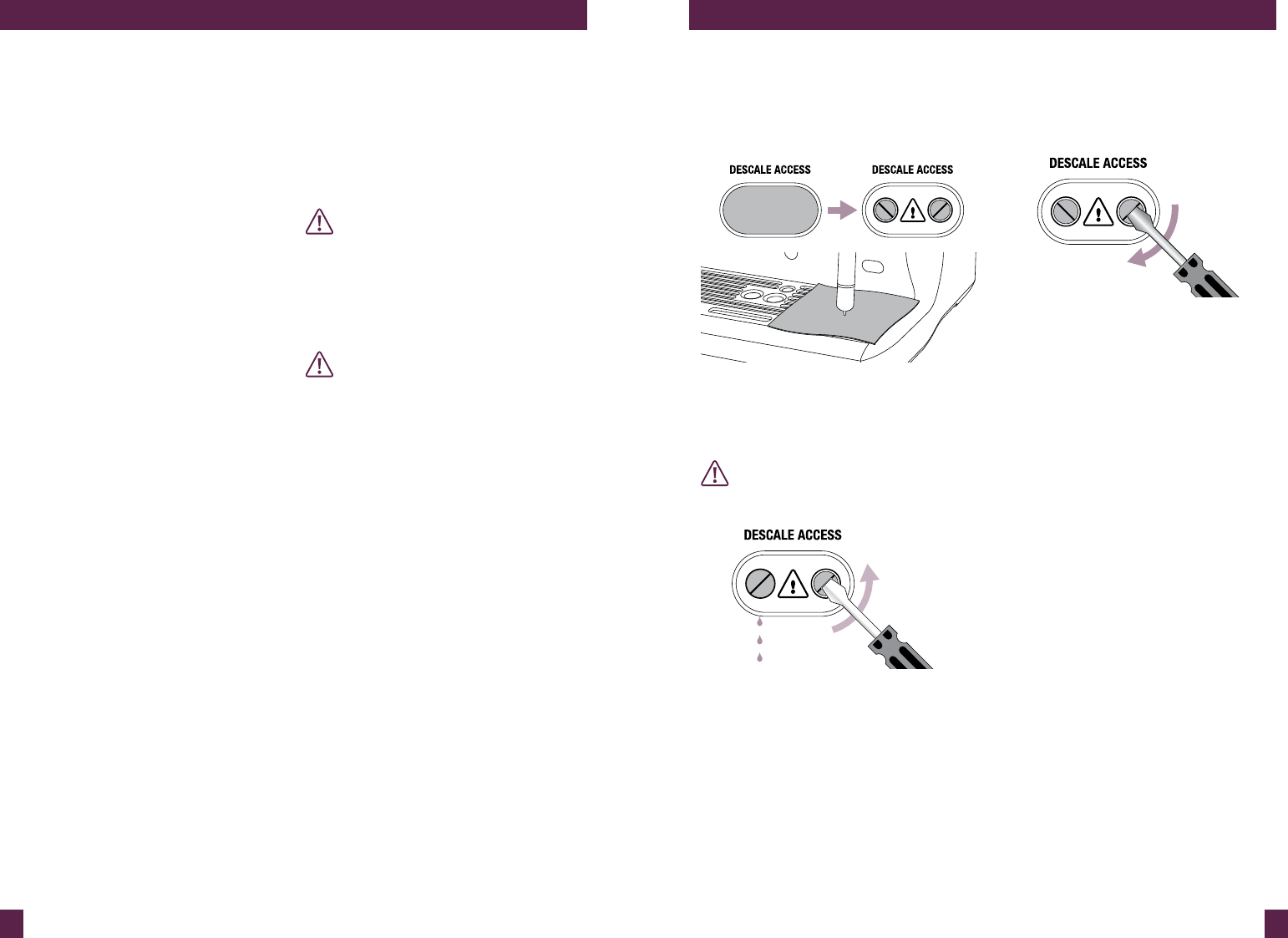

a) Remove the grey silicone cover on the

lower front panel marked DESCALE

ACCESS. Place a cloth over the

drip tray to stop steam escaping.

REMOVE

b) Use a flat-head screwdriver to rotate the

right screw counter-clockwise until the

valve is fully open. As the valve opens,

steam may be released.

CAUTION

HOT WATER & STEAM

c) Next, repeat the above process on the

left screw. As the valve is opened, water

may begin flowing into the drip tray.

d) Allow valves to remain open until no

more water or steam escapes.

e) Close both valves by rotating screws

clock-wise until seated. Do not

overtighten screws to avoid damaging

the valves. Replace the grey silicone

cover over the valves.

f) Empty drip tray and reinsert into

position. Use caution as the drip tray

may be hot due to the water and steam

from the boilers.