SBB00101-1-1007 Page 15

GAS CONVERSION TO NATURAL GAS

A conversion kit to natural gas is included with your grill.

1. Remove cooking grids and flame tamer from grill.

2. Use allen wrench supplied in conversion kit to remove control

knobs.

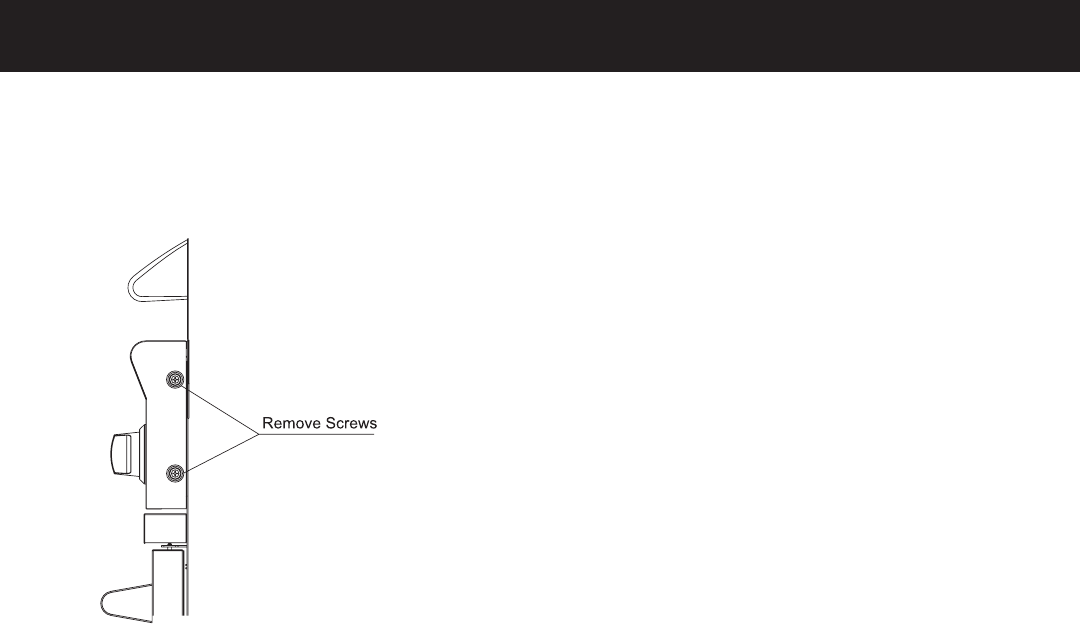

3. Remove control panel (4 Phillips screws).

Figure 18

4. Use a 7mm socket or wrench to remove all LP gas orifices

marked 1.02 from gas valves.

5. Install natural gas orifices marked 1.51 into gas valves. Apply

pipe compound to threads on orifices prior to installation.

6. Attach left side of control panel to grill with two (2) Phillips

screws from Step 3. Carefully insert left burner orifice into left

burner. Continue to carefully insert the remaining orifices into

the burners. Attach right side of control panel to grill with two

(2) Phillips screws from Step 3.

7. The low input adjustment screws are located inside the main

burner valve stems. Use small screwdriver supplied in conver-

sion kit to turn each adjustment screw clockwise 1/4 turn (90

degrees).

Attention (SBG2501 and SBG2801 Only): The valve stem

that is second from the left side of the grill is the rotisserie

valve stem and it will not be adjusted.

8. Remove rotisserie burner back cover (5 Phillips screws - four

on the back and one on inside top of the back of the grill).

9. Use a 14mm wrench or adjustable wrench to remove LP

gas rotisserie orifice marked 0.84 for SBG2501 and 1.02 for

SBG2801 from orifice fitting.

10. Install natural gas rotisserie orifice marked 1.18 for SBG2501

and 1.51 for SBG2801 into orifice fitting. Apply pipe com-

pound to threads on orifice prior to installation.

11. Remove the hose and regulator from the gas connection on

grill with an adjustable wrench.

12. Connect the grill to the natural gas supply.

13. Attention: Before lighting your grill check all gas connections

including the adjustment screws in valve stems for gas leaks

with a soapy water mixture.

Caution: Do not use the grill if a gas leak is detected until gas

leak is corrected. If a gas leak can not be stopped, do not use

grill. You must contact a qualified repair person.

14. Replace back panel (5 Phillips screws from step 8).

15. Replace all control knobs with allen wrench.

16. Apply the completed conversion label adjacent to the rating

plate label on the right side panel of the cart.

17. The natural gas inlet pressure at the grill is to be set at 7.0” of

inlet pressure.

18. Ignite burners on grill and observe flame pattern. If flame is

yellow in color or flame is lifting off burner, the air shutter on

burners will require adjustment.

19. Turn OFF (but do NOT remove) natural gas supply to grill.

20. Loosen (but do NOT remove) two (2) Phillips screws at end

of each burner. Lift upward and pivot burner out of grill.

21. Loosen Phillips screw at air shutter. Air shutter for natural gas

should have about 1/4” opening. Open air shutter for a yellow

flame or close air shutter for a lifting flame. Tighten Phillips

screw at air shutter.

22. Replace burners into grill. Tighten two (2) Phillips screws at

end of each burner.

23. Ignite burners on grill to verify burner flame characteristics.

Installation must conform to local codes or, in the absence of local

codes, with the National Fuel Gas Code, ANSI Z223.1. In Canada,

installation shall be in accordance with CAN/CGA-B149.1 Natural

Gas Installation Code, and local codes where applicable. Contact

your local gas company for code regulations, recommended pro

-

cedures, and the installation of your grill’s gas supply line.

Caution: The grill and its individual shutoff valve must be dis

-

connected from the gas supply piping system during any system

pressure testing at test pressures in excess of 1/2 PSIG.

Caution: The grill must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 PSIG.