11

11. Clean all grinding burrs and mounting surfaces

before reassembly.

12. Install the four .250"-20 cage nuts on the new

motor.

13. Place the new motor with hopper collar and

bushing into position on the bushings on the

motor mounting bracket.

14. Using four .250"-20 screws, flat washers and

rubber washers secure the motor to the mount-

ing bracket.

15. Install stationary burr (9) to the grind chamber

housing using two .250"-20 screws.

16. Install burr (7) and burr auger rotor/spring as-

sembly (3) on to motor shaft.

17. Install motor shaft extension (11) on motor

shaft.

18. Align the slot in the motor shaft extension (11)

with the slot in the burr auger rotor/spring as-

sembly (6) and install shear plate (4).

19. Install burr rotor cup (5).

20. Install grind selector dial plate and grind selec-

tor knob assembly on the grind chamber hous-

ing and secure with two .250"-20 screws.

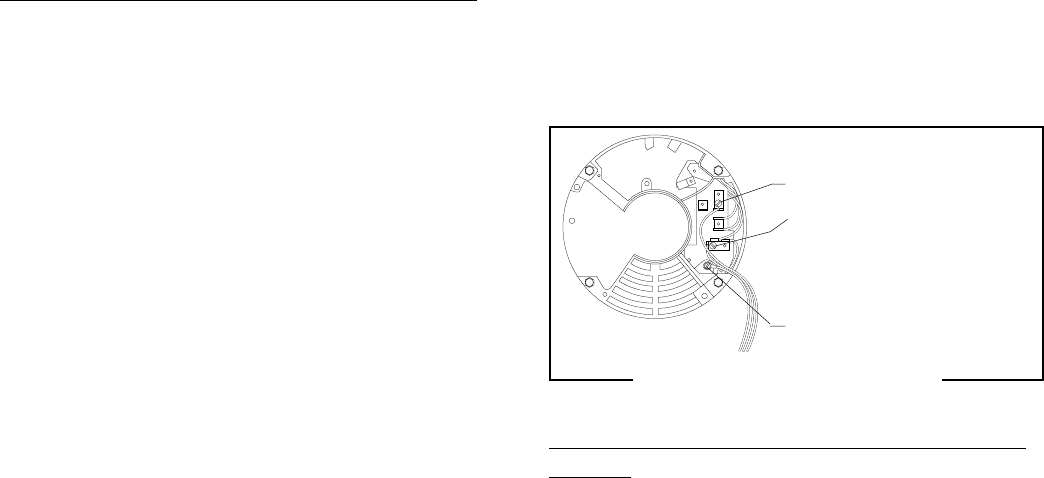

21. Refer to Fig. 5 and reconnect the wires.

22. Refer to

ADJUSTMENTS

on page 5 and reset

the burrs.

SERVICE (cont,)

AC MOTOR AND GRIND CHAMBER (cont.)

black and white/blue wires on terminals L1 &

L2 with a voltmeter. Connect the grinder to the

power source. When the Off/On/Start switch is

momentarily placed in the “START” (lower) po-

sition and then left in the “ON” (center) posi-

tion and a bag is in place behind the coffee dis-

pense chute.Plug-in the grinder. The indication

must be:

a. 120 volts ac for two wire 120 volt models.

b. 230 volts ac for two wire 230 volt models

c. 240 volts ac for two wire 240 volt models.

5. Disconnect the grinder from the power source.

If voltage is present as described replace the motor.

If voltage is not present as described, reconnect the

white, red or red/black and white/blue wires to the

motor, refer to the Wiring Diagrams and check the

grinder wiring harness.

Removal and Replacement - Motor (Refer to FIG.6):

1. Remove the plate on the rear of the motor and

disconnect all wires from the motor.

2. Remove the two .250"-20 screws (1) securing

grind selector dial plate and grind selector knob

(2) to the grind chamber. Remove dial plate and

selector knob as an assembly.

3. Slide burr (7), auger rotor/spring assembly (3),

shear plate (4) and burr rotor cup (5) off the

grinder motor shaft as an assembly.

4. Remove the two .250"-20 screws (8) securing

the stationary burr (9) to the grind chamber.

5. Remove bushing (10) and shaft extension (11)

from the grinder motor shaft.

6. Remove the two #8 thread forming screws (12)

securing the fill plate (13) to grinder housing

and remove plate (13).

7. Remove the four #10-24 screws (14) securing

the chute assembly (15) to the grind chamber

and remove chute assembly (15).

8. Remove the four .250"-20 screws, flat washer

and rubber washers securing the motor to the

mounting bracket.

9. Remove motor out the rear of the grinder hous-

ing.

10. Remove the four .250"-20 cage nuts from the

motor mount.

WHI/BLU to

Relay N.O.(K4)

WHI to Cordset (120V)

RED/BLK to Cordset (230V)

GRN to Ground (120V)

GRN/YEL to Ground (230V)

P1310

Removal and Replacement - Grind Chamber - Refer

to Fig. 6:

1. Loosen the two set screws (16) securing the

grind selector knob to the grind selector dial

plate (18) and remove knob.

2. Remove the adjusting screw w/bearing (19).

Inspect adjusting screw w/bearing for wear.

Replace if excessively worn or damaged.

FIG. 5 AC MOTOR TERMINALS