45

SERVICE (Cont.)

Left

Right

WHI/ORN to

Timer P4-4

RED/BLK to

Right Solenoid

RED/BLK to

Timer P4-7

WHI/YEL to

Timer P4-5

RED/BLK to

Left Solenoid

P612

Location:

The solenoids are located on the mounting plate

immediately beneath the hoppers.

Test Procedure:

1. Unplug the grinder.

2. Connect a voltmeter across the left or right solenoid

coil terminals. Plug-in the grinder. Momentarily

press the Off/On/Start switch to “START” (lower)

position and release (hopper selector switch must

be corresponding to the suspect solenoid). The

indication must be 120 volts ac for 120V models

and 230 volts ac for 230V models.

3. Unplug the grinder.

If voltage is present as described, proceed to #4.

If voltage is not present as described, refer to the Wiring

Diagram and check the grinder wiring harness.

4. Separate the connectors on the white/brown wires

of the solenoids from the connectors on the grinder

wiring harness (RED/BLK) and the limit thermo-

stat.

5. Check for continuity across the white/brown wires

on the suspect solenoid coil.

If continuity is present as described, reconnect the

white/brown wires to the grinder wiring harness, and

proceed to #6.

If continuity is not present as described, replace the

solenoid.

6. Check for continuity across the terminals of the

limit thermostat.

P608

If continuity is present as described, reconnect the

wires, and proceed to #7.

If continuity is not present as described, replace the

limit thermostat.

7. Check the solenoid for coil action when the control

switch is momentarily pressed to the “START”

(lower) position and released. Plug-in the grinder.

Listen carefully in the vicinity of the solenoid for

a “clicking” sound as the coil magnet attracts and

after a period of time, repels the plunger.

8. Unplug the grinder.

If the sound is heard as described and the plunger

remains unable to move or move freely, refer to the

slide plate section.

If the sound is not heard as described, replace the

solenoid.

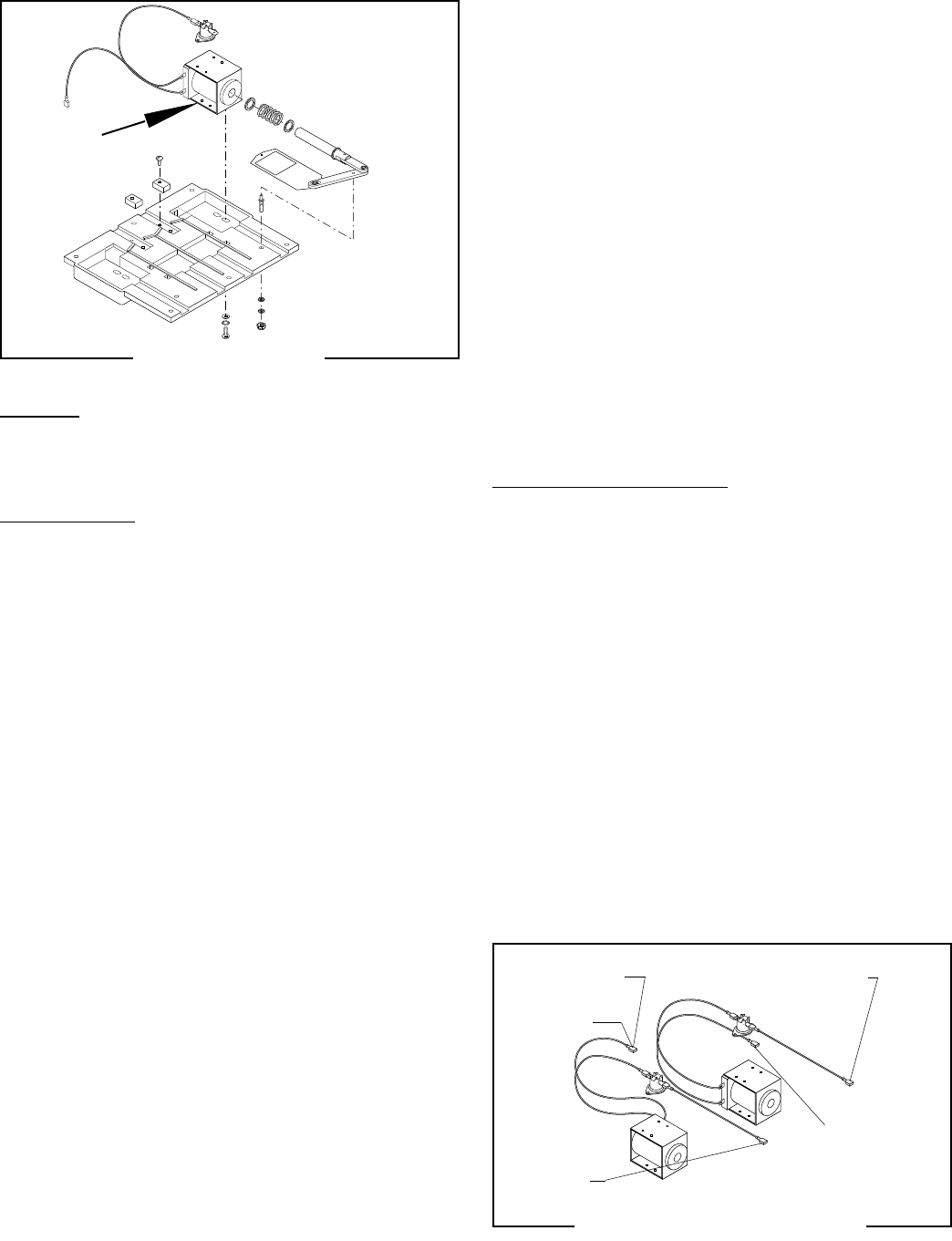

Removal and Replacement:

1. Remove the hopper assy from the grinder.

2. Remove the four 8-32 slotted-head screws holding

the solenoid coil to the solenoid panel.

3. Feed the white/brown wires through the hole in the

solenoid mounting plate and loosely install the new

solenoid coil.

4. Look through the collector on the bottom of the

assy and adjust the slide plate travel distance when

installing the solenoid coil.

5. Push the solenoid plunger into the solenoid coil

with your hand while moving the coil forward or

backward in its mounting holes.

6. Securely tighten the mounting screws when the

slide plate appears to have no metal showing in

the front or back of the hopper hole.

7. Refer to the following illustration when reconnect-

ing the wires.

Solenoids (Models MHG, FPG-2 DBC, LPG-2, G9-2, G9-2 DBC)

FIG 46 SOLENOIDS

FIG 47 SOLENOID TERMINALS

41545 122209