14

Control sequence

To start — Local start-up (manual start-up) is initiated by

pressing the LOCAL or CCN menu softkey, which is indi-

cated on the default international chiller visual control

(ICVC) screen. Time schedule 01 or 03, respectively, must

be in the Occupied mode and the internal 15-minute start-

to-start and the 1-minute stop-to-start inhibit timers must

have expired. All pre-start safeties are checked to verify

that all prestart alerts and safeties are within limits (if one is

not, an indication of the fault displays and the start will be

delayed or is aborted). The signal is sent to start the cooler

liquid pump. Five seconds later, the condenser liquid pump

is energized. If satisfied, it checks the chilled liquid temper-

ature against the control point. If the temperature is less

than or equal to the chilled liquid control point, the con-

denser liquid pump is deenergized and the chiller goes into

a recycle mode.

If the chilled liquid temperature is high enough, the start-

up sequence continues. The oil pump is started and waits a

minimum of 45 sec to verify oil flow. Once oil flow is veri-

fied, the VFD is energized. The control will monitor for a

phase reversal condition. At this time, the following occurs:

• The “start-to-stop” timer is activated.

• The “compressor on-time” and “service on-time” timers

are activated.

• The “starts in 12-hour counter” advances by one.

• The “total compressor starts counter” advances by one.

Once started — If the VFD average current >5% within

15 seconds after VFD start, the machine enters run mode

and speed will be ramped up to meet VFD target speed.

Once the target speed is met the controls, enter the capac-

ity control mode.

Shutdown sequence — The chiller shutdown is initiated

if any of the following occur:

• The Stop button is pressed for at least one second (the

alarm light blinks once to confirm the stop command).

• A recycle shutdown is initiated.

• The time schedule has gone into unoccupied mode.

• The chiller protective limit has been reached and the

chiller is in alarm.

• The start/stop status is overridden to stop from the

ICVC, CCN system, or building management system.

Once the controls shutdown sequence is initiated, the

compressor is stopped and the VFD target speed is set to 0.

If optional soft stop unloading is activated when the Stop

button is pressed or the remote contacts open, motor

speed decreases to a configured amperage level, and the

compressor is stopped. The display indicates “Shutdown in

Progress” while the motor speed decreases. Compressor

ontime and service ontime timers stop once the current in

all phases is <5%, indicating a VFD Stop Complete. The oil

pump and cooler liquid pump are then deenergized. The

condenser liquid pump shuts down when the refrigerant

temperature or entering condenser liquid temperature is be-

low pre-established limits. The 3-minute start-to-stop timer

starts.

Restart — Restart is permitted after both inhibit timers

have expired. If shutdown was due to a safety shutdown,

the reset button must be depressed before restarting the

chiller.

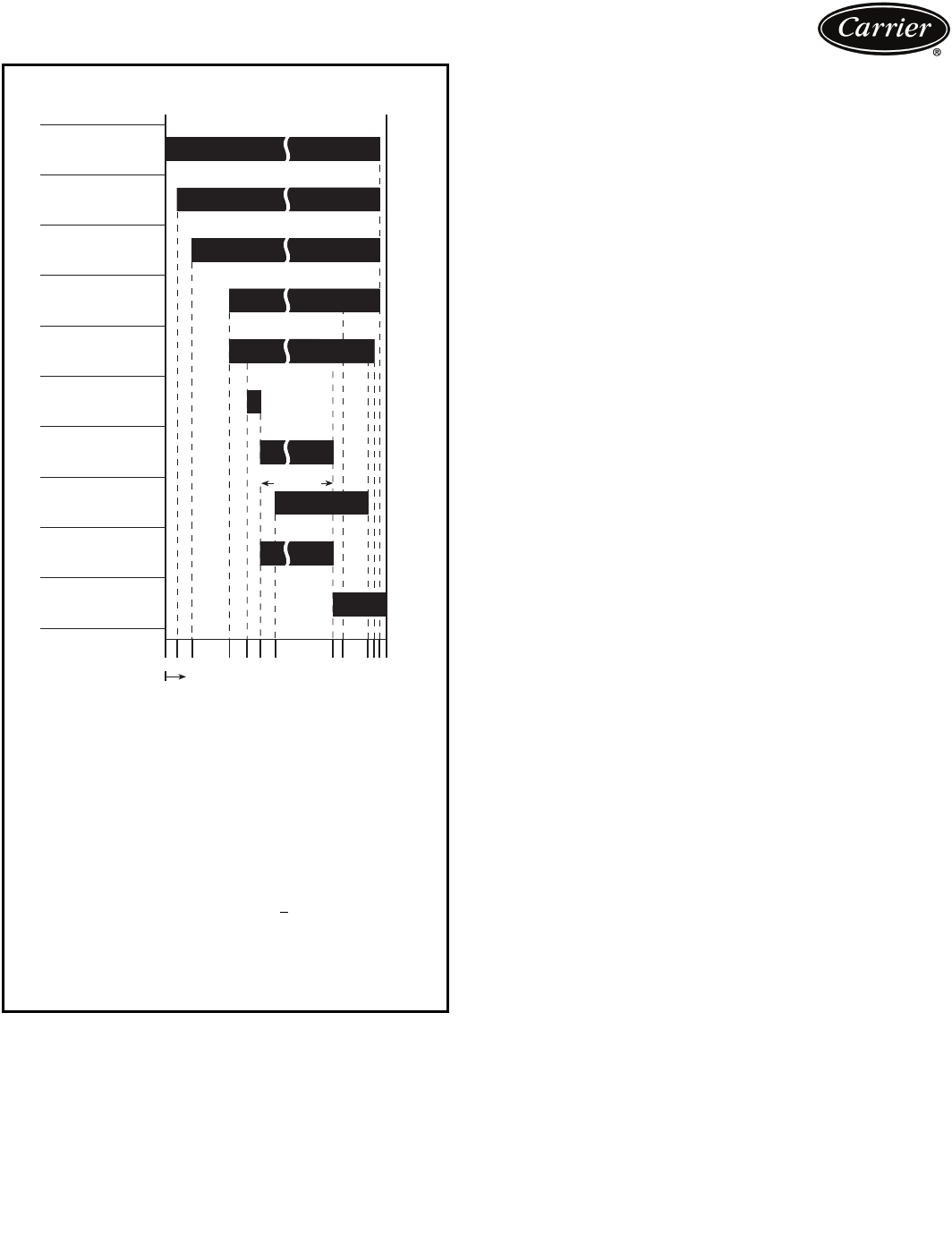

Controls (cont)

MACHINE SAFETIES,

EVAPORATOR PUMP

CONDENSER WATER

PUMP

WATER FLOWS

CHILLED WATER

TEMP,

CONTROL

OIL PUMP

OIL PRESSURE

VERIFIED

VDF FAULT TEST

COMPRESSOR, PHASE

REVERSAL,

COMPRESSOR AND

SERVICE ONTIME

1-MINUTE

STOP-TO-START

TIMER (SOFTWARE

VERSION 13)

15-MINUTE

START-TO-START

TIMER

RAMP VDF TO

TARGET SPEED

COMPRESSOR

RUNNING

A

B

C

D

E

F

G

H

IJ

K

L

O/A

TIME

TOWER FAN

0 0

CONTROL SEQUENCE

0—Phase reversal monitored

A—START INITIATED: Pre-start checks are made; evaporator pump

started

B—Condenser liquid pump started (5 seconds after A); tower fan control

enabled

C—Liquid flows verified (30 sec to 5 minutes maximum after B)

D—Chilled liquid temperature checked against control point; oil pump

on.

E—Oil pressure verified (oil pressure verified 45-300 sec after D).

F—VFD starts; phase reversal conditions monitored; compressor

ontime and service ontime start; 15-minute inhibit timer starts (VFD

fault tests for 15 sec after F)

G—Verify average current >5% within 15 sec after VFD start, ramp to

VFD target speed.

H—Compressor reaches target speed, chiller set to running status

I—Shutdown initiated: Target VFD speed to 0% (or J occurs)

J—Ramp down until percent line current <

soft stop amps threshold

(0-60 sec after I)

K—Oil pump relay off (1-20 sec after J)

L—Evaporator pump deenergized (60 sec after K); condenser pump

and tower fan control may continue to operate if condenser pressure

is high; evaporator pump may continue if in RECYCLE mode

O/A — Restart permitted (both inhibit timers expired) (minimum of 15 min-

utes after F; minimum of 3 minutes after L)